Service case:

Jiaxing Processing Center Wins Praise for Processing Petrochemical Tower Inner Parts (2023)

Daming Jiaxing Machining Center has been delivering orders for tower parts in batches. The “one-stop” service of quick delivery, excellent cost and high quality has won the praise and recognition from customers.

It is understood that the processing material for the 304L, a variety of finished products, the main specifications of the 3-8mm range, need to be cut, leveling, rounding, bending, and structural parts of the welded molding and other procedures, and the customer put forward strict requirements for the processing accuracy of the product.

In order to ensure the high quality delivery of the products, Daming Jiaxing Processing Center quickly set up a special team including business, production, technology, quality, etc., and give full play to the advantages of the process performance of Daming’s advanced equipment, through the fixed machine and manpower, multi-departmental close cooperation, as well as the strength of the “one-stop” full-process processing strength, and ultimately high quality and efficiency to complete the processing! Before the formal processing, all production units were working closely with each other.

Before formal processing, each production unit based on customer demand, in-depth discussion of drawings, the development of the optimal feasibility of the processing program, followed by strict control of every gate in the processing, so that customers really experience from the material to the multi-channel processing, as well as technical support, cost control, fast delivery, quality assurance and other aspects of the heart-saving, assured, comfortable service.

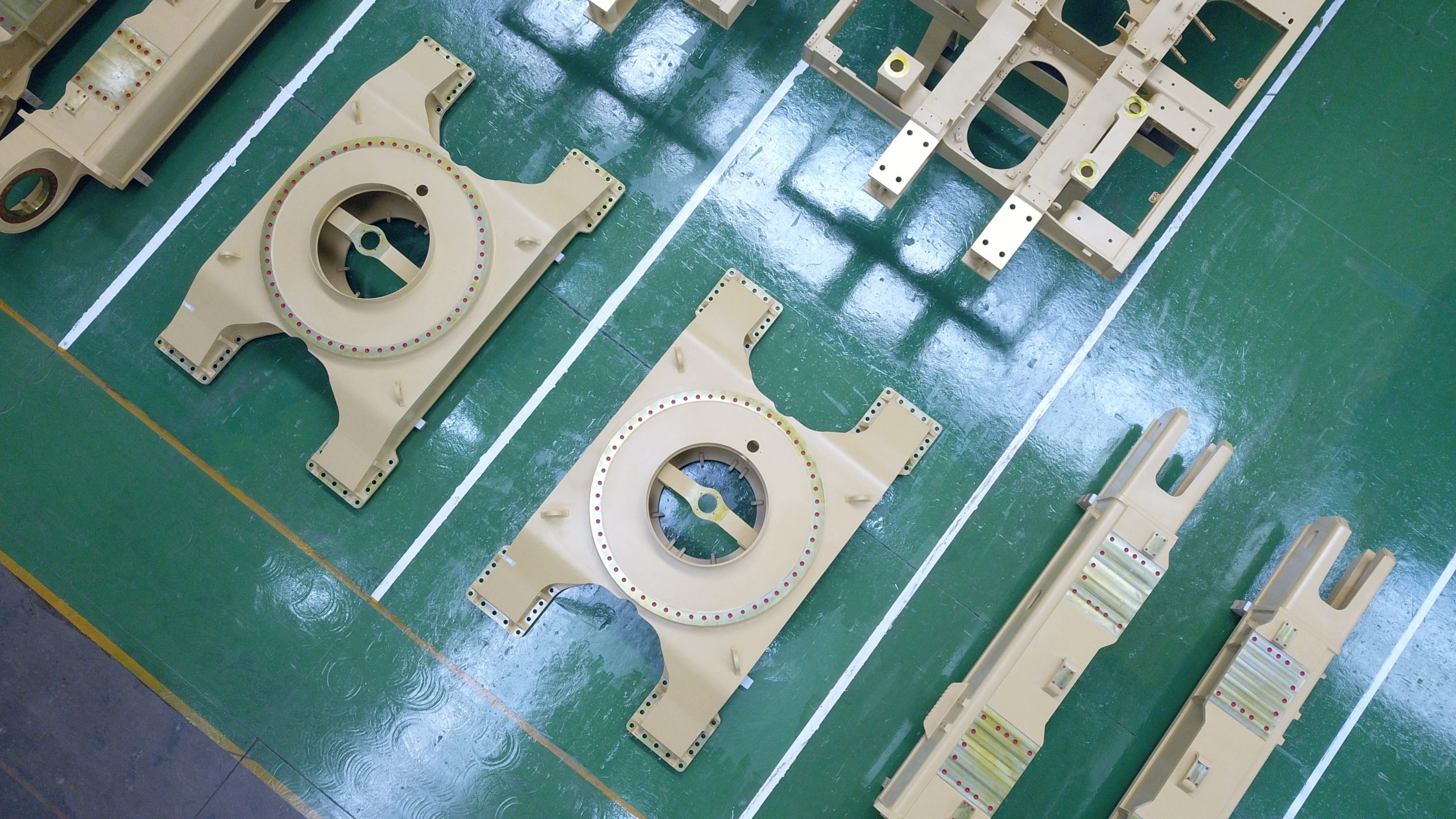

Customer on-site inspection of products

Hubei machining center was praised for the processing of petrochemical tower parts (2023)

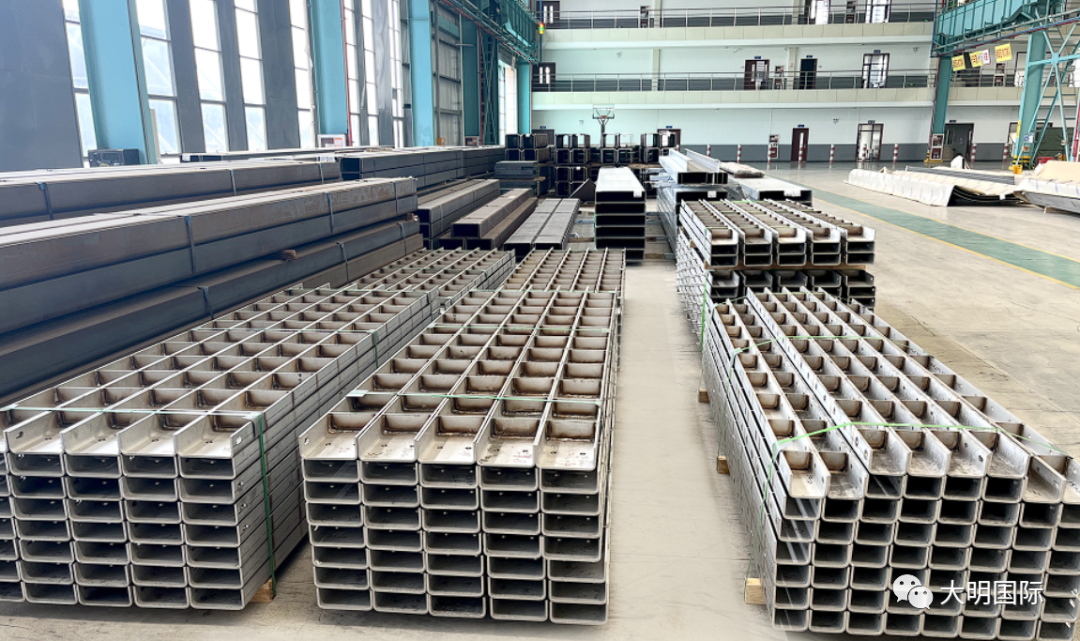

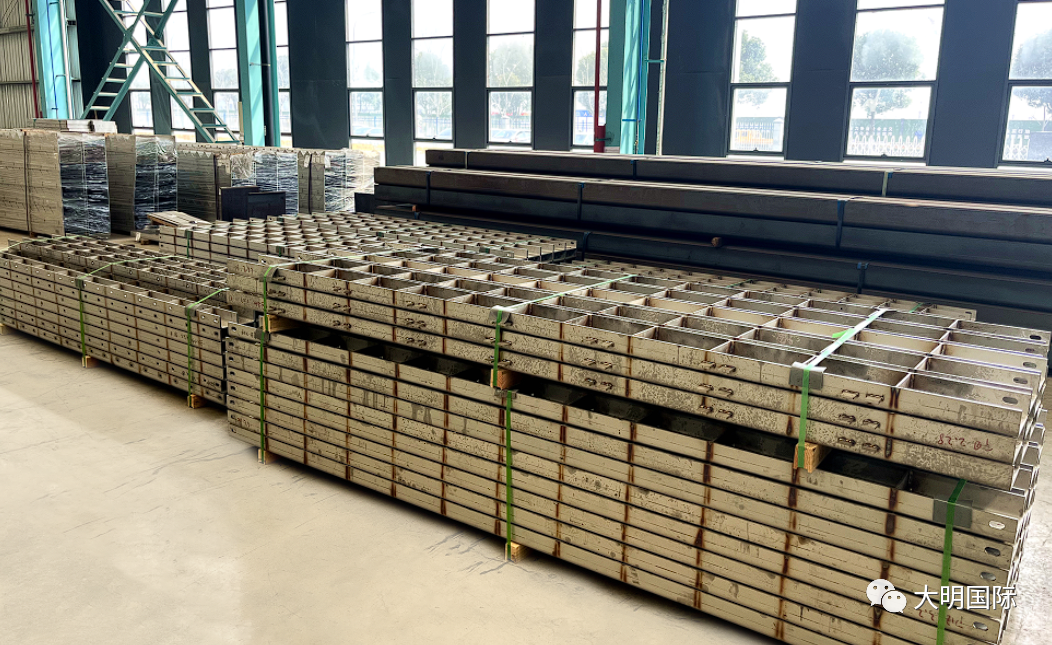

Daming Hubei Processing Center successfully completed the processing of a batch of tower parts for a petrochemical unit. Fine process control, high quality products, and detailed sorting and packaging were appreciated by the customer.

This batch of orders up to more than 1,200 pieces, will be supporting foreign projects, the surface of the processed parts, processing precision and other high requirements. In order to avoid product defects in the process of discharging, bending, packing, etc., and to ensure the machining accuracy, the company’s production department has taken a series of measures to ensure that the quality of the customer’s needs, and at the same time, the business department took the initiative to communicate with the customer, for the product specifications, the number of products, the size of the parts is similar to the use of the order and the part of the actual packaging solutions and proposals, and gained a high degree of recognition of the customer.

Customers to the production site inspection, praised the processing product quality and packaging ” excellent “, especially the detailed classification and packaging for its on-site installation to save a lot of time, will greatly enhance the processing efficiency.

“Once also processed a batch of very many parts of the product, but not like this from beginning to end of the fine control and detailed classification and packaging, so that the product to the factory after the arrangement of the three people spent a few days to sort out the classification, ‘tossing people and delay’, a comparison of the “big company details is to do well”. The customer compared and praised Daming. –The customer compared and praised Daming

The customer said that they would continue to cooperate with us for the second batch of more than 1,000 products. Daming will continue to practice the concept of “customer-centered”, and continue to provide customers with high-quality, detailed service.

Daming Hubei machining center high quality service for petrochemical enterprises (2020)

With advanced cutting and bending equipment, Daming Hubei Machining Center has been providing a lot of high-quality deep processing services for petrochemical equipment manufacturers. Recently, Daming Hubei machining center again received a batch of orders from a petrochemical equipment enterprise with high quality requirements of multiple varieties.

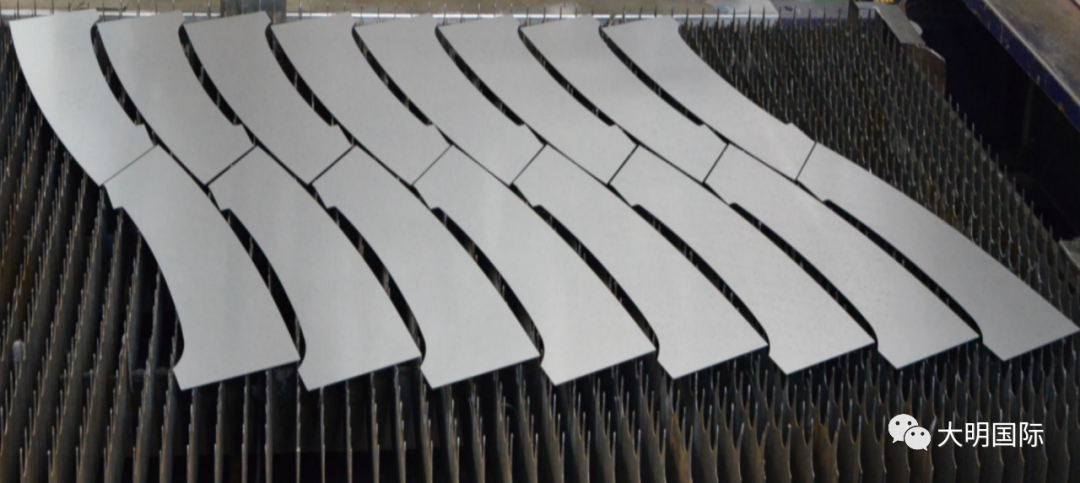

The customer was satisfied with the results of the first trial samples before placing an order for mass production, the material is made of 304 stainless steel, thickness 10-12mm, a total of more than 2600 pieces for precision tower parts. The drawing requirements are very strict, and there are many types, involving slitting, flattening, cutting, bending and other processes. Due to the petrochemical equipment companies have very high requirements for products, Daming Hubei machining center technicians in the process of processing layers of control, a combination of multiple equipment sub-blade sequence for batch processing, to improve production efficiency at the same time to ensure the stability and consistency of the size of the finished product of the bending, and ultimately the delivery of the finished product dimensional accuracy is fully qualified, which can be used for the later assembly welding to save time, and won the customer’s satisfaction.

Hubei Daming optimized processing service for tower inner parts of petrochemical equipment plant (2017)

Hubei Daming provided a batch of supporting tower inner parts for a petrochemical equipment enterprise, which was praised by the customer by optimizing the material processing mode, improving the utilization rate of the material, reducing the cost and improving the quality for the customer.

This batch of material is 3-4mm thick, 100-400mm wide and 4000-6000mm long, the traditional processing mode of the tower parts in this industry is to use 1500*6000mm size flat plate cutting and welding of the excess edge material to utilize the finished product when the width of the narrower shear plate is prone to sickle bends, which adversely affects the subsequent punching and bending process. Hubei Daming makes full use of the raw edge part of the original coil, and the utilization rate of the material is nearly doubled by mixing multiple sizes, and the flatness and dimensional accuracy of the material is ensured by slitting and flat steel leveling equipment.

The customer also purchased a batch of 3mm thick, 34mm wide slitting material for subsequent angle processing. Hubei Daming used advanced Italian VIGANOSL8.0 slitting equipment, with two rows of knives to slit 44 strips, which ensured the quality of the finished product and improved the material utilization rate.

Daming Sheet Metal Batch Matching Petrochemical Reaction Tower (2017)

Daming Sheet Metal has successfully completed the production and delivery of a batch of petrochemical equipment reactor tower internal parts for a Japanese-funded equipment enterprise.

Based on last year’s successful cooperation on two overseas projects, the customer has once again engaged Daming Sheet Metal for in-depth cooperation this year. The products processed this time were the inner parts of reaction towers for petrochemical equipment, with more than 900 tons of materials used, tens of thousands of products, and many varieties of products. The main processing techniques of the products include flattening, cutting, bending, machining, rounding, welding and so on. This project has posed a great challenge to Daming in terms of planning and scheduling, quality control, delivery schedule and transportation guarantee. By giving full play to the advantages of multi-departmental, cross-platform, and molecular company cooperation, Daming not only ensured the overall delivery date of the project, but also verified the strong execution and collaboration ability of the Daming team once again.