- mpj@jsdmss.com

- No.1518 Tongjiang Road, Wuxi, Jiangsu, China

- Home

- About DamingAbout Daming

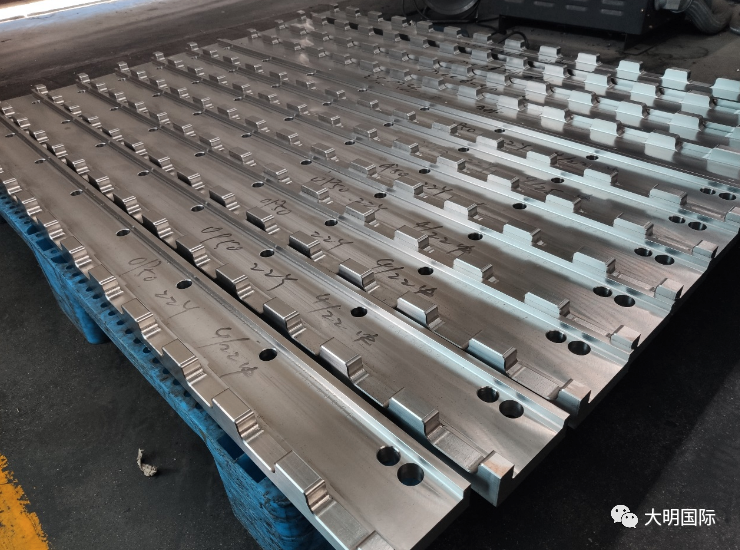

Founded in 1988, DAMING is a leading enterprise in metal processing and high-end manufacturing supporting service fields and could provide whole process services of fabrication, spare parts and finished products manufacturing and professional technical services.

Main Menu

- Material ServicesMaterial Services

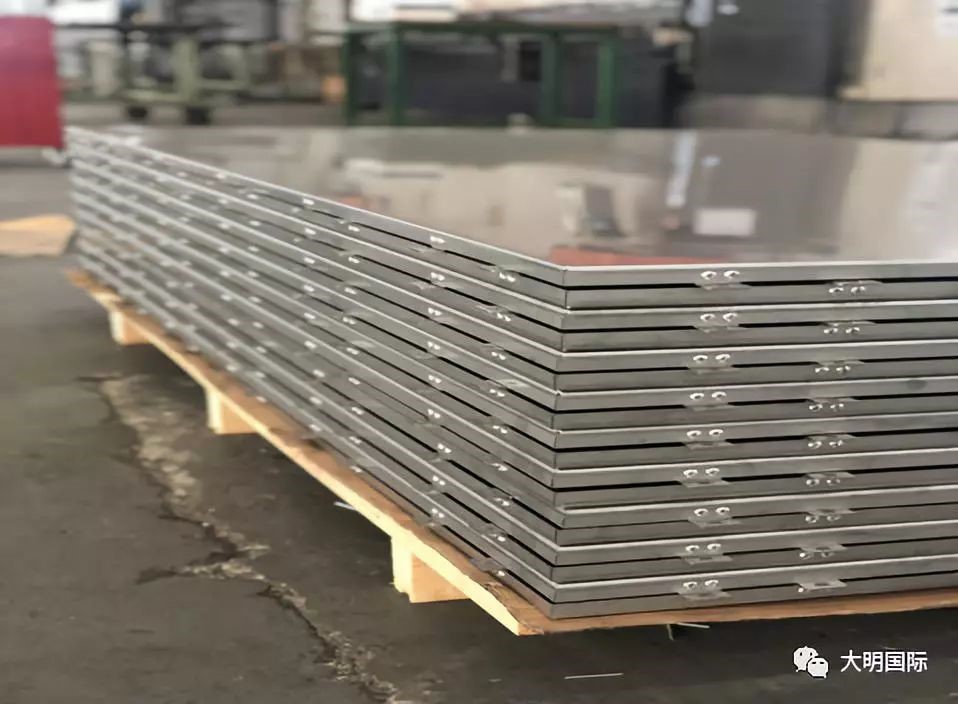

Daming aspires to become a national manufacturing steel processing and supply center and stainless steel, carbon steel spot supermarket chain, standing stainless steel inventory of 160,000 tons, carbon steel inventory of 300,000 tons, 20,000 tons of special materials.

Main Menu

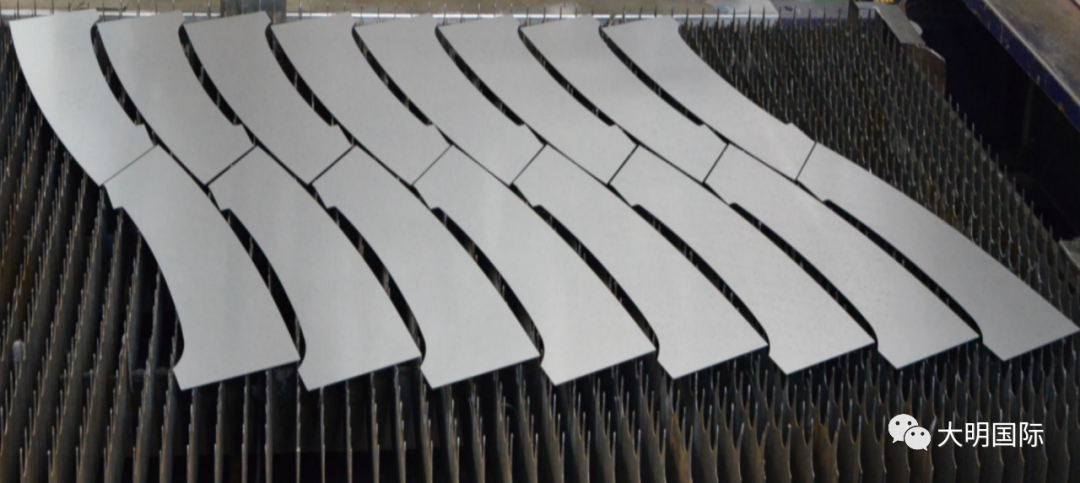

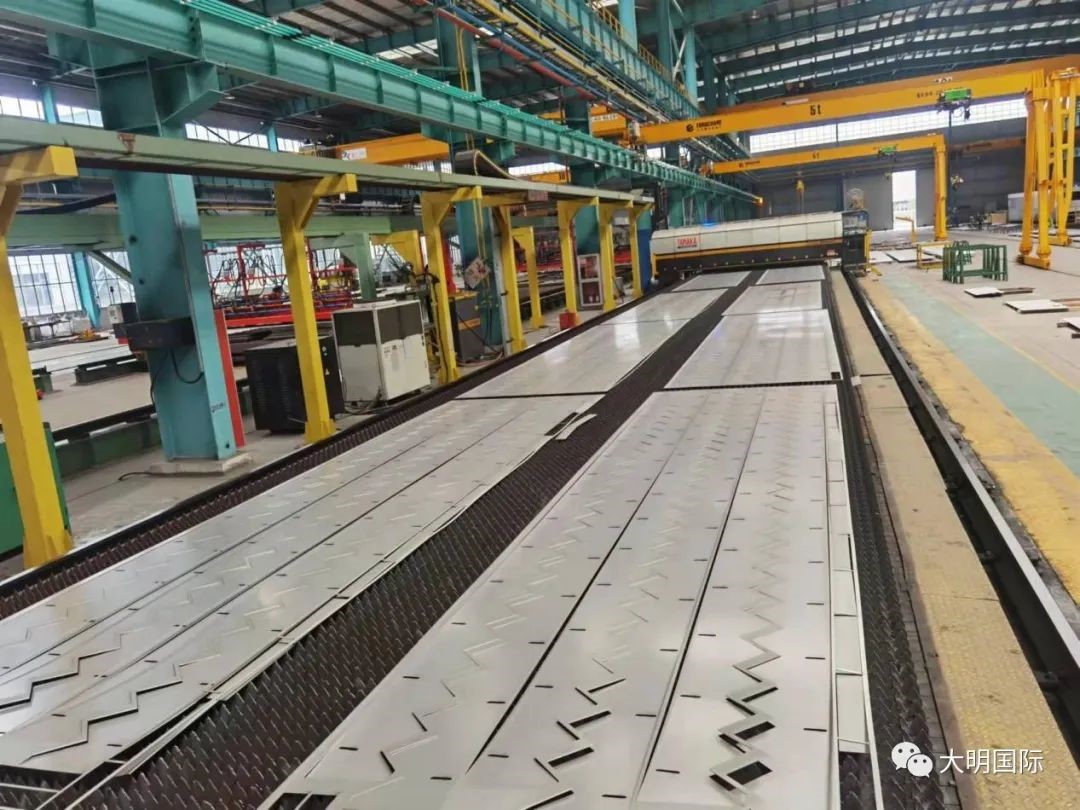

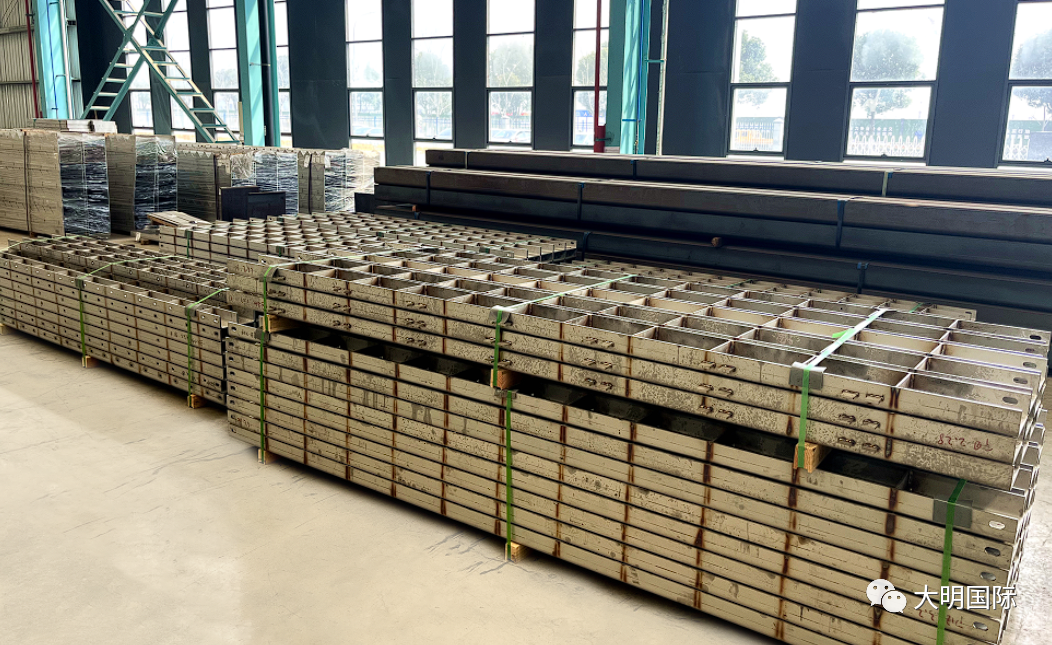

- Service scopesService scopesDaming supplies services for material processing of steel materials, fabrication of various types of spare parts, semi-finished products, and finished product manufacture supporting services.Main Menu

- Business Industry

To create “More, Faster, Better, Cost-Effective” stainless steel processing and manufacturing platform for high-quality products.

Specialist in processing services for high-strength steel and other carbon steel varieties.

Daming has outstanding competitiveness in the service field of large engineering projects represented by large tank prefabrication service.

Based on the export base in Wuxi, Daming Import & Export Company will link up Daming’s ten processing centers and manufacturing.

- News

- Contact us