In the semiconductor and solar cell equipment industry, Daming, as a professional stainless steel parts and components supplier, with the advantages of rich material resources, coherent process platform, group synergy and linkage, as well as the unique competitive “one-stop” service mode, can provide single crystal furnace base plate, cylinder cover, elliptical cavity and photovoltaic module carrier plate products, crystalline silicon furnace accessories, vacuum cavity accessories, vacuum semiconductor such as vacuum coating machine Cavity processing for projects, silicon single crystal growth furnace processing projects, semiconductor template processing projects, vacuum isolation cover projects and other diversified products of the whole process of production services, can meet the customer customization, diversified materials and processing needs.

Sharing benefits and common development, Daming’s net material processing model serves vacuum semiconductor industry

Quality, cost, delivery time, is the main advantage and solemn commitment of Daming to serve customers. 2020, Daming Group Stainless Steel Division from the perspective of sharing benefits and common development with customers, to further optimize the marketing model, the implementation of the net material processing mode has brought visible to customers.

Case Review:

On August 12, a batch of new energy photovoltaic mounting products exported to a certain country in Europe, serviced by Daming Import & Export and Daming Precision Manufacturing Company, were successfully sent out from Shanghai port.

Products loaded for shipment

This batch of photovoltaic bracket order is made of 304 stainless steel, with a total of about 25,000 pieces, the thickness of the material is 5 different specifications, which involves multiple processes such as cutting, grinding, bending, welding, color removal and deburring, packaging, etc.

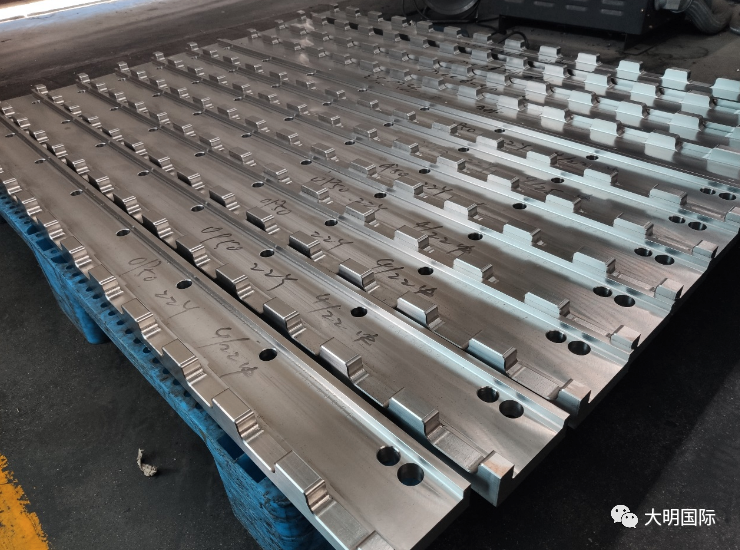

The production site of Daiming Precision’s photovoltaic bracket

Against the backdrop of Europe’s serious lack of energy, solar energy has great potential for development. The country has sufficient light resources, which is ideal for the construction of photovoltaic power stations. This photovoltaic project will help the construction of local single photovoltaic power station and improve the new energy supply service.

Daming packs with care and meticulousness

Daming closely follow up the development needs of photovoltaic energy, and in production, relying on advanced equipment and professional team service advantages, by trying a number of improvement measures, and constantly optimize the cost of photovoltaic products, process, quality and delivery, etc., and ultimately successfully completed the delivery of the order to win the customer’s full acceptance, and it is expected that the subsequent cooperation between the two sides of the order will be exponentially increased.

Case Review:

Jiangsu Daming machining center precision department is a busy scene, is for a foreign enterprise batch processing vacuum coating equipment parts.

It is understood that this batch of vacuum coating equipment selection thickness of 2.0-50mm specifications of 304 stainless steel, a total of 19 products more than 1300 pieces, processing involves polishing, leveling, laser, waterjet, bending, machining and other processes. As the vacuum coating equipment is very concerned about the quality of the supporting equipment, the flatness of the plate surface, the distance between the apertures, the uniformity of polishing, bending angle and other requirements are very high. Daiming has rich experience in supporting vacuum semiconductor equipment and has provided services for nearly 70% of the manufacturers in the industry. The quality and efficiency of this processing has been recognized by the customer again, and the completed products have passed the acceptance.

Case Review:

Vacuum semiconductor industry, equipment application environment is harsh, do not accept the welding process options, the whole plate cutting became the only choice.

Daming has served a square product outer frame length of about 1500mm, the inner frame length of about 1400mm, the shape of the characteristics of the decision of the whole plate cutting material utilization is very low, the pressure of the cost of the customer once worried. After understanding the situation, Jiangsu Daming provided a set of “net material + processing” cooperation mode for the customer, and the customer only needs to bear the cost of the actual material used. For the residual material produced during cutting, Daming can digest the material later through scientific scheduling, set of material processing, which not only reduces the loss but also optimizes the manufacturing cost for the customer, which can be said to be a win-win situation. After preliminary estimation, this program can directly reduce the material cost for the customer about 30%.

After determining the cooperation program, Daiming from the selection of high-quality 304 medium-thickness plate to the oil grinding, cutting, machining of the coherent production in one go. 20 sets of parts have been processed through the acceptance.

The advantages of the net material processing mode are not only limited to cost reduction, but also have a full grasp of the quality and delivery time, relying on the complete variety and reliable quality of the steel material service platform and many “high precision, high efficiency” advanced processing equipment clusters imported from Europe, the United States, Japan and other developed countries.

Case Review:

Daming Jiaxing machining center has processed several batches of orders for a well-known semiconductor industry veteran customer, and finally completed the work smoothly under the perfect cooperation of multiple people and multiple machines. Advanced equipment performance, efficient service team, strong processing capacity, and quality “one-stop” service, etc., have won the high appreciation of the customer.

This batch of monocrystalline silicon needs to go through multiple processes such as slitting, flattening, cutting, edge planing, etc. The customer puts forward high requirements on product precision and has a tight delivery schedule.

In order to better serve the customer, the production team discussed and formulated a suitable processing program, relying on advanced processing equipment, rich experience, overtime, while strictly controlling the production process, the implementation of the first inspection, sampling, final inspection, and ultimately the quality and quantity of one day ahead of the delivery date to complete the delivery, and get the customer’s praise.