At present, Daming has successfully accumulated experience in processing and manufacturing prefabricated parts for containers and tanks in many industries such as bio-fermentation, food and beverage, brewing and pharmaceuticals. The “package” prefabricated solution with excellent cost, high quality and quick delivery has won the recognition and praise of many leading enterprises in the industry.

Case Review:

Daming two processing centers join hands to support overseas high-end food machinery

This project is a kind of wall panels for overseas high-end food machinery. This order is jointly contracted by Tianjin TISCO Daming and Jiangsu Daming, with a total of 28 pieces of double-sided oil-ground 304 stainless steel with a thickness of 16mm. Processing involves double-sided oil grinding, laser cutting, gantry machining, clamping and other processes. The customer made clear requirements on size, shape, flatness and hollowing angle. During the production process, the two machining centers sales department, technology, production and other departments work closely together to develop appropriate production and testing standards, the use of imported advanced equipment, processing in an orderly manner to ensure that the quality meets the requirements.

Case review:

Jiangsu Daming signed an order for the first batch of nearly 1,000 tons of stainless steel products for a domestic bio-fermentation project, adding a headline to the New Year’s opening in 2021.

It is understood that the bio-fermentation project requires a total of more than 3,000 tons of 304 hot-rolled stainless steel sheet, the project team examined a number of suppliers, and finally chose to cooperate with Jiangsu Daming. Under the guidance of the company’s leadership, Jiangsu Daming hot rolling department minister Yuan Kang led the team members, around all kinds of large and medium-sized projects, the market whole single order, the customer loose single order and other needs, to “more” (stainless steel varieties and specifications, spot inventory), “fast” (“fast order, fast processing, fast delivery”), “fast processing, fast delivery”, “fast delivery”, “fast delivery”, “fast delivery”, “fast delivery”, “fast delivery”, “fast delivery”. Order fast, processing fast, pick up fast), “good” (good quality, good service), “save” (save time, save material, save heart) professional services, and constantly improve the level of service and customer satisfaction, to win more and more customer recognition.

Case review:

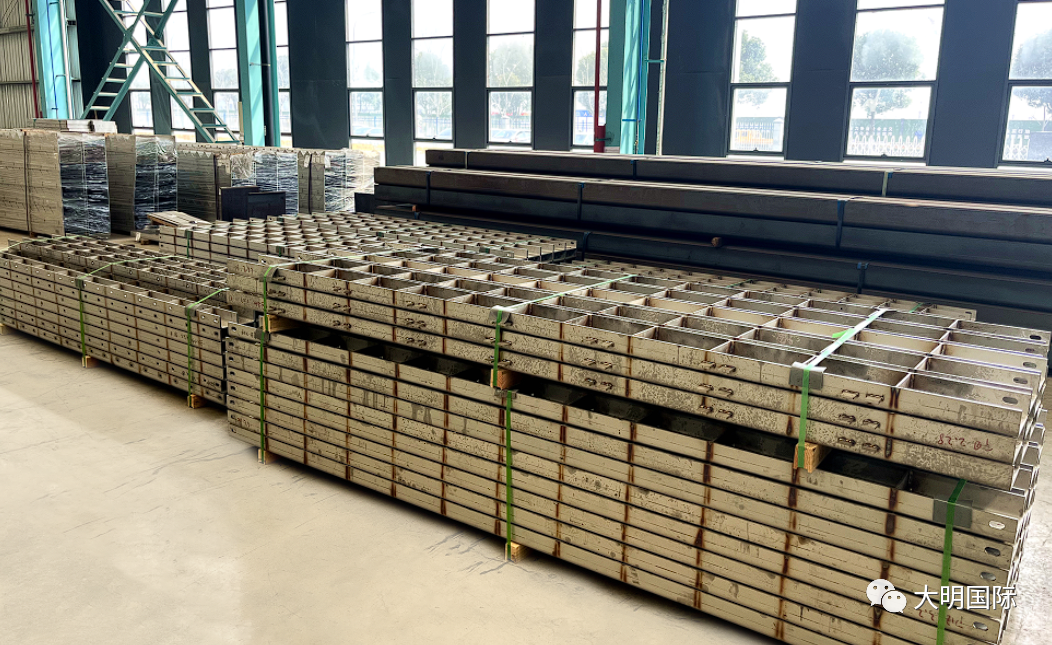

The products supporting the bio-fermentation project invested by Jiangsu Daming for a grain and oil giant in Northeast China have been processed and shipped one after another.

It is understood that this project Jiangsu Daming hot rolling department tracked for half a year, through the installation company to provide optimized processing solutions, to provide the owner with optimized material selection, joint installation company to take the project. Among them, the 304 and 316L hot rolled stainless steel materials totaled 1200 tons, thickness 5-16mm, width 1500mm, length 6000-9000mm. the processing involves the process of flattening, slitting, laser cutting and so on.

This batch of material processing requirements are high, the project delivery time is also very tight. Affected by the epidemic, the construction site resumed work in mid to late March, at this time the progress of the site has been seriously lagging behind, the project installation company and the hot rolling department of Jiangsu Daming emergency contact, hoping to coordinate support, speed up the speed of supply, and strive to catch up with the delivery date, will be delayed by the epidemic to catch up with the time back. Hot Rolling Department project staff urgently convened a project-specific meeting to discuss solution measures. After ventilating with the Planning Department, Production Department and Quality Control Department, they formulated the processing requirements and schedule, and arranged the processing in strict accordance with the customer’s requirements and delivery time nodes.

At present, Daming Steel Union Logistics has shipped the products one after another, and the first two batches have been delivered to the customer’s site, which has been well received by the project installation company and the owner.

Case review:

Daming Hangzhou machining center again for the domestic famous food machinery enterprises supporting a batch of side outer sealing plate products, with excellent processing strength to successfully complete this batch of orders.

The thickness of this batch of products is 3mm, the material is 316L, the surface is NO4+, and the length of the finished products is about 8m-12m. The products need to go through several processes such as sanding, slitting, leveling, cutting, etc. The customer has high requirements for the surface of the products, so it is very important for them to have a high quality product. The customer has high requirements for the surface of the product, and also has high requirements for the dimensional accuracy. In response to the customer’s demands, Daming Hangzhou Processing Center selected Tanaka 6000W laser equipment from Japan, giving full play to the advantages of the equipment’s large worktable and the high cutting accuracy of the equipment, and ultimately high-quality support for the customer to obtain a high degree of recognition from the customer.

Case review:

Jiangsu Daiming develops new products of stainless steel sauce bucket

A few days ago, Daming for a food group to develop and manufacture 1000 stainless steel sauce bucket new products delivery.

The food group is a well-known enterprise in the domestic industry, mainly engaged in the deep processing of agricultural and food products, and signed a contract with Jiangsu Daming for the processing of 1,000 sets of stainless steel sauce barrels, with a production cycle of 1.5 months. Processing technology involved in the leveling – laser – circle – back round – welding – assembly – grinding. The barrel body has a large mouth and small bottom, with a height of 1 meter, and is made of high-quality S30408 with a thickness of 4mm, all of which are laser welded on both sides. In the type of bending circle, using customized spiral profile bending, in order to facilitate the subsequent welding assembly. Green materials, exquisite craftsmanship, Da Ming with professional processing services to obtain customer praise.