When projects call for diverse steel part specifications, strict tolerance standards, and rapid delivery schedules, many suppliers hesitate. For Shandong Daming, however, such challenges are opportunities to showcase its leadership in steel technology, production management, and customer service.

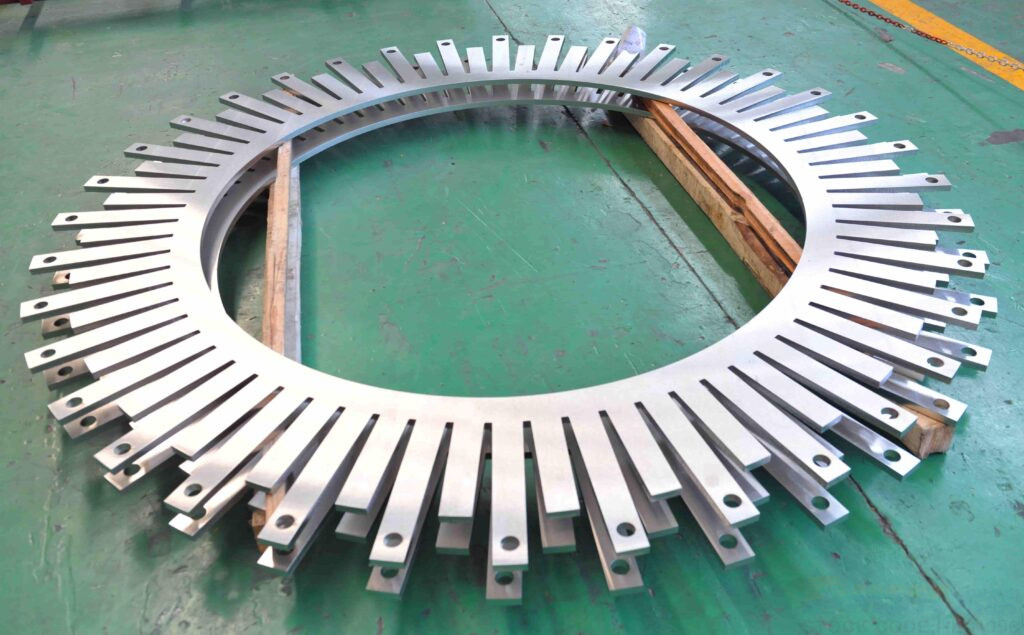

Recently, by seamlessly integrating advanced laser cutting technology with straightening and machining processes, Shandong Daming successfully completed a batch of high-precision steel components for a special equipment manufacturer. The company’s expert craftsmanship, fast response, and efficient delivery earned strong recognition and trust from the client — reinforcing a long-term partnership.

Swift Response and Seamless Collaboration

Upon receiving the client’s steel component specifications, Daming immediately formed a “rapid-response” task force, combining expertise from business, process engineering, production, and quality control.

Leveraging years of experience with high-power laser cutting of medium- and heavy-gauge steel plates, the team quickly optimized the processing workflow. By fine-tuning parameters such as laser focus, cutting speed, air pressure, and duty cycle, Daming achieved one-pass precision cutting and forming of steel plates within strict tolerances, ensuring consistent dimensional accuracy.

During production, operators maximized equipment performance while maintaining rigorous control over every cutting and straightening step. As a result, all trial steel parts passed strict inspections and met every technical requirement.

Racing Against Time: Delivering Steel Parts Ahead of Schedule

With a tight delivery deadline, the Daming team demonstrated exceptional professionalism. Continuous coordination across laser cutting, straightening, machining, deburring, and steel packaging stages enabled production, logistics, and quality teams to share real-time progress updates.

By overcoming bottlenecks, reallocating capacity, and tackling technical challenges in medium- and heavy-gauge steel, the team completed the order ahead of schedule — saving the client critical time for on-site assembly.

The client commented:

“Daming’s steel components meet the highest precision standards, and its service is unmatched.”

This project highlighted Daming’s comprehensive strength in steel technology, management, and service, reinforcing its commitment to delivering ongoing value through skilled teams and advanced equipment.

Daming Custom Steel Cutting: One-Stop, Worry-Free Service

More than just stainless steel or carbon steel cutting, Daming provides full end-to-end steel processing solutions — including leveling, beveling, forming, and welding — offering a truly one-stop experience.

By combining premium steel materials, cutting-edge equipment, innovative processes, skilled professionals, and rigorous quality management, Daming efficiently delivers tailored steel solutions for clients across multiple industries, from construction and machinery to special equipment manufacturing.

Core Advantages of Daming’s Custom Steel Services

✅ Comprehensive Steel Cutting Methods

Laser, flame, plasma, and water jet cutting capabilities allow Daming to design the optimal steel processing route for every project.

✅ Flexible Customization, Zero Minimum Order

Daming’s signature “Zero Cutting” service accepts even single-sheet steel orders. Clients can submit drawings for irregular shapes — including fan-shaped or polygonal steel parts — without batch limitations.

✅ Reliable Steel Sources

Partnering with top mills such as Taiyuan Iron & Steel, Zhangpu Steel, and Qingshan Steel, Daming guarantees consistent quality, certified steel, and full traceability.

✅ Advanced Equipment for Differentiated Steel Service

Equipped with cutting-edge machinery — including a 60,000-watt laser cutter — Daming ensures superior precision, faster cutting speeds, thicker steel processing, optimized material use, and reduced costs.

✅ Strict Process Control, Assured Quality

Every operator functions as a “steel quality inspector.” Through Daming’s 3Q full-quality chain management system, clients can trust every stage — from raw steel to final delivery.

Striving for Excellence, Creating Greater Steel Value

For years, Shandong Daming has been dedicated to delivering high-quality steel processing services — continuously refining processes and enhancing the customer experience.

Looking forward, Daming will strengthen innovation-driven development, expand technical steel capabilities, and foster interdepartmental synergy — all to provide clients with ever-improving, high-end steel solutions that truly live up to the company motto:

“No best — only better.”