Daming Jingjiang base is determined to become the largest, most professional and most authoritative pipe plate processing base in China, which can help customers in many industries to improve processing efficiency, shorten the delivery cycle, reduce manufacturing costs, and effectively ensure the high precision of the pipe plate, so that the tolerance is small and the finish is good.

Material diversification: Relying on the friendly cooperation with steel mills, we have rich and diversified material resources to choose from, which can shorten the material customization cycle for customers and save the transportation cost of repeated turnover.

Comprehensive process: Relying on the top processing equipment cluster, we can provide multiple processes from material to cutting, beveling, welding, heat treatment, vertical turning, drilling and so on;

Capable of processing tube plates and folding plates made of diversified materials such as pure titanium, stainless steel composite, high-specification stainless steel and various high-strength steels;

Provide technical support for irregular hole shapes such as jeweled holes, toothed holes, rhombic holes, etc. in addition to common round holes to meet customer customization needs;

To be able to solve the processing of pipe plate and folded flow plate with a diameter of more than 6m for customers; the maximum processing diameter of the whole circle is 10 meters, and the maximum drilling depth is 1.1 meters.

Sufficient experience and excellent quality: it has the manufacturing qualification and supervision of many products such as pressure vessels, etc. It has mature experience in manufacturing pipe plates in the industries of pressure heat exchanger, nuclear power, petrochemical and energy, etc. It has been selected in the list of qualified suppliers of CITIC Heavy Industries, Shanghai Electric and many others;

Adopting high-quality machining tools and reasonable frequency of tool change, we effectively ensure high precision and defect-free tube sheet under experienced production operation;

With material physical and chemical laboratories, flaw detection equipment, machining inspection volume and other rich quality inspection means, can ensure the high precision of the product.

High efficiency and fast delivery: multiple sets of equipment combined processing batch, high efficiency (for example, drilling can be drilled 120 kilometers per month, the peer is far ahead; deep hole drilling maximum drilling depth of 1.2 meters, double / triple-axis processing at the same time, the efficiency of the traditional method is 2-3 times. Multi-hole drilling supports multiple spacer stacking, with a large table and high efficiency); Daming’s overall strong anti-risk ability, coupled with the support of the local government and the JIT service of Steel Union’s logistic system and other guarantees, helps customers to shorten the delivery cycle.

Saving customers’ cost: We can customize scientific and reasonable pipe processing plan to improve the material utilization rate for customers;

“One-stop” service avoids the influence of multi-party procurement on customers’ management cost and delivery time;

Advantages such as complete materials (avoiding repeated turnover), excellent quality (long equipment life), etc., greatly saving customer costs.

It can not only process products in batch with high efficiency, but also meet the demand of individual customization.

This is the standard configuration of CNC machine tools in Daming Heavy Industries Precision Company.

Here, large table machine tools, multi-hole drilling, deep hole drilling, vertical lathes and other advanced machining equipment clusters, for the “one-stop” high-efficiency, fast delivery of the pipe plate processing provides strong support, really help customers to realize the cost reduction and efficiency.

Under the support of mature technology, the company has a processing capacity of 120 kilometers of drilling per month, which is the absolute leader in the industry, creating the largest and most professional and authoritative tube sheet processing base in China.

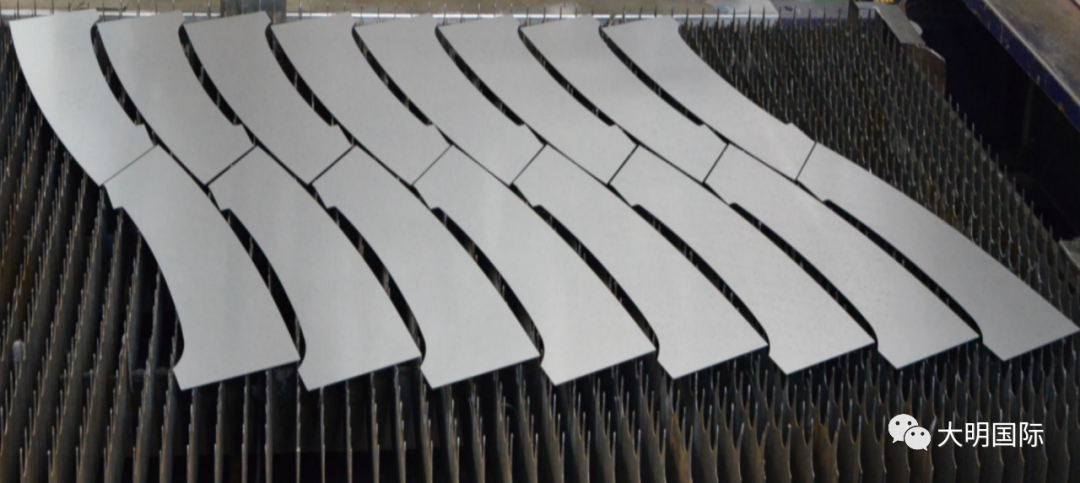

So what are the clusters of advanced equipment for precision machining such as turning and drilling with ultra-high efficiency in Daming?

The base has advanced drilling and turning equipment at home and abroad that can serve tube and plate processing, 11 deep hole drilling, 31 CNC multi-hole drilling, 11 CNC lathe equipment, realizing precision tube and plate machining services with high processing precision, full specifications and multiple functions.

Various types of lathe equipment.

The base has a turning and milling composite machining center represented by Wuzhong, which has high cutting efficiency and can easily realize the functions of turning, milling, boring, drilling, tapping and countersinking.

For example: Wushong 12.5m vertical lathe, which has a maximum machining diameter of 12.5m, a maximum machining height of 6,000mm, and a maximum capacity of 400 tons of workpieces, adopts the world’s leading Siemens 840DSL numerical control system, double-tool holder structure, constant-speed cutting, automatic indexing and clamping.

All kinds of drilling equipment:

The base has many imported multi-hole drilling and deep-hole drilling equipments such as Italian Insea, Korean Dayang, Shenyang Zhongjie and Wushong.

For example: Insea deep hole drilling, the maximum drilling depth of pipe plate is 1.1 m. The maximum drilling depth is 1200 mm, 12 mm ≤ hole diameter ≤ 55 mm, which has the characteristics of stable hole size, excellent hole wall roughness, high verticality, etc., and is capable of machining pipe plate with plate thickness of 1200 mm, realizing simultaneous machining of two-axis and three-axis, and the efficiency is 2-3 times of that of the traditional machining method. In a short period of time, the company has processed 24 pieces of 260mm thick and 6000mm diameter stacked welded pipe plates for a large-scale enterprise, and processed 12mm hole diameter high-precision pipe plates made of special materials for an energy enterprise, which is regarded as the “star product” of machining.

For example: Dayang multi-hole drilling, the maximum processing of the outer diameter of the pipe plate 10 m. Can be four-axis simultaneous processing, support for multiple spacer stacking, processing table, high efficiency, length * width 12000mm * 10000mm, the deepest 300mm, the maximum hole diameter of up to 105mm. has served the central air-conditioning, boilers, heat exchangers, seawater desalination, power plants and other industries.

It once processed the world’s largest diameter spliced welded pipe plate for Vimed Paper Project. For two large enterprises to process the diameter of about 8000mm, thickness of about 200mm pipe plate, a single machine drilling nearly 2,000 meters per day. Processed more than 400 pieces of duplex steel seawater desalination pipe bulkheads for a large chemical enterprise, serving the largest seawater desalination plant in China. A total of 5 million holes were completed in less than 2 months, which was highly appreciated by the customer.

Whether it is processing 1.5mm small holes, or more than 100mm large holes, or any hole type customized by the customer, Daiming, relying on the advanced equipment cluster and rich experience in service, the efficiency of drilling machine processing has a remarkable performance, and there are many cases of successful service, and the customer satisfaction is very high.