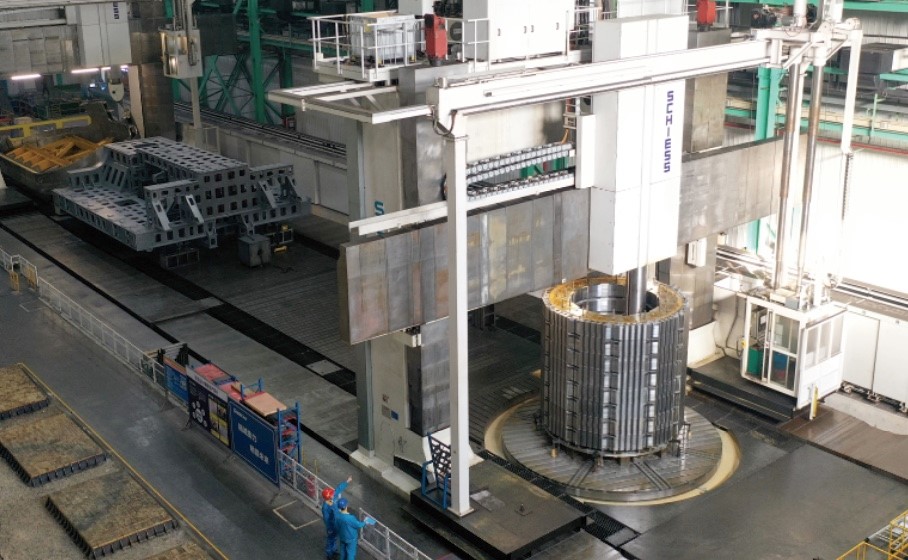

In terms of supporting services for the new energy industry, Daming is committed to building a whole industry chain supporting services system for the new energy industry, providing “package” manufacturing solutions for the new energy industry, relying on the “one-stop” service platform from materials to multi-process combined processing to semi-finished products and parts manufacturing, and helping customers effectively solve the problem of “intermittent procurement is not easy to control the quality of each process” brought about by multiple procurement. Relying on the “one-stop” service platform from materials to multi-process combined processing, to semi-finished products and parts manufacturing, and with the advantages of “excellent cost, excellent quality and excellent delivery”, we help customers effectively solve the problem of “intermittent purchasing, which is not easy to control the quality of each process” brought about by multi-party purchasing, “dispersed suppliers, long turnaround time between processes”, “large supplier management costs” and other problems, helping customers to effectively enhance competitiveness.

Relying on the uniquely competitive service model in the field of high-end equipment manufacturing, Daming International can provide a “package” of service solutions for the lithium industry chain by utilizing the group’s function of linkage and collaboration.

Daming Light Manufacturing Company, Jiangsu Daming, Daming Heavy Industry Heavy Precision Manufacturing Branch and Daming Jingjiang Processing Center have efficiently collaborated to give full play to the group’s linkage service advantages, and through the “one-stop” service of material selection, processing, distribution and after-sales service, it has successfully completed the urgent order of shells for a leading lithium battery enterprise, which was highly praised by the customer.

The customer is a world-renowned manufacturer of mixing and stirring equipment, specializing in the production of various types of industrial mixing, stirring, dispersing, emulsifying and other equipment, mainly used in new energy, chemicals, coatings, pharmaceuticals, adhesives and other industries, and has been a long-term service to the world’s top 500 companies and leading enterprises in various industries.

The lithium batteries of this cooperation will be widely used in the new energy industry, and Daming in the new energy industry lithium industry chain services to ensure the supply, relying on the unique competitiveness of the service model advantage, linkage and collaboration, and successfully provide a “package” solution:

Product drawing design;

Parts selection and optimization;

Process analysis and optimization;

JIT just-in-time logistics;

“Butler-type” attentive after-sales service;

In this lithium battery case service, Daming Light manufacturing company gives full play to its own advantages of batch welding, assembly, overall scheduling, etc., in cooperation with Jiangsu Daming and Jingjiang machining center, accurate material selection, rapid discharging, molding, machining, coupled with the advantages of high efficiency of precision manufacturing and batch production of Daiming Heavy Industry, the success of the sampling in 2 months, and completed more than 100 sets of products. 2022 will continue to work with the customer in-depth cooperation is expected to be less than 1,000 sets of this product for the whole year. The whole year is expected to be no less than 1,000 sets of this product.

This successful service is the efforts of both parties to continue to promote strategic cooperation and deepen EVI cooperation, but also the customer, as a leading lithium battery enterprise, the relentless pursuit of the ultimate quality, new materials, new processes upholding the attitude of open cooperation.

In the future, Daming will continue to link steel mills and new energy upstream and downstream industry customers for in-depth cooperation, to help the whole industry chain realize carbon neutrality as soon as possible, and Daming Light Industry will be committed to serving the needs of more new energy customers with higher efficiency and better quality.

Case Review:

Daming lithium industry chain project service;

Daming Wuxi processing center for one of China’s largest lithium materials intelligent factory EPCC service providers, a lithium enterprise integrated production line processing silo products trial samples successfully, and cooperation 100 sets of first order.

Influenced by the high boom of new energy vehicle market, the global lithium industry chain has been developing rapidly in recent years. 2022 since the beginning of the year, Daming Wuxi Processing Center for one of China’s largest lithium material intelligent factory EPCC (design, procurement, construction, drive) service provider of a lithium enterprise integrated production line supporting the silo products first trial samples completed, and has signed 100 sets of first order of the product.

On January 14, the customer quality, technical personnel came to Wuxi Processing Center and Jiangsu Daming jointly set up the welding processing workshop site, and made 2 sets of welding samples made a rigorous test, the final parts size accuracy, welding quality and so on have been recognized.

The welding process in the customer requirements of the premise of argon arc welding, Daming technology and processing staff to make bold attempts, a set of sample parts using argon arc welding, a set of sample parts using laser welding.

Finally adopted the laser welding workpiece, both welding efficiency, or weld aesthetics have been improved substantially, the customer is very satisfied. The later use of laser welding process for mass production, not only capacity and efficiency will be improved, and production costs will be significantly reduced.

Case review:

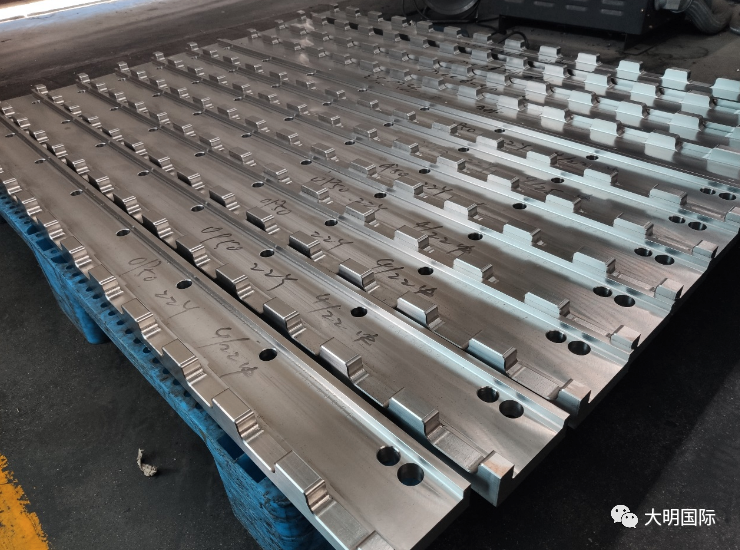

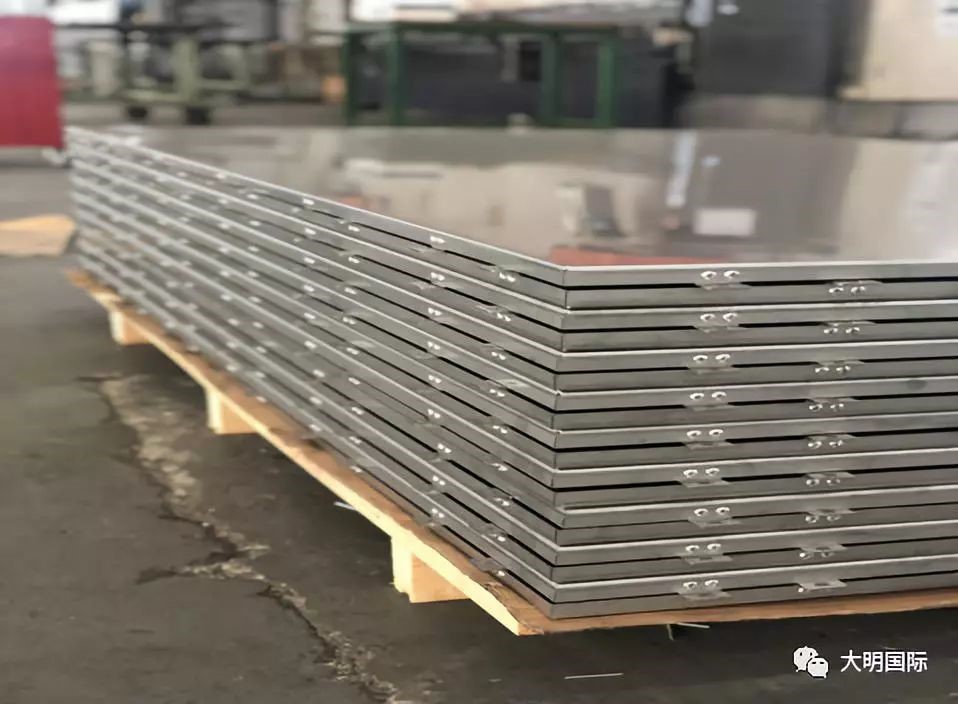

Jiangsu Daming machining division processing high-end lithium battery project container bottom plate;

A batch of container base plates for the lithium battery project is being made by the machining division of Jiangsu Daming, and is expected to be delivered on schedule in 15 days.

The lithium battery project container bottom plate processing order contracted by Jiangsu Daming Engineering Services Department, the selection of 1.0-80mm thickness of multi-series 304 stainless steel, involving fiber optic, plasma, laser, waterjet and other cutting processes. Customers have clear standards for the quality of the plate and the quality of the processing process. Through the business, production, technology and other continuous communication, Jiangsu Daming strict processing quality standards are carried out in each link to ensure that each workpiece is completed at once.

At present, Daming’s supporting services have covered a number of new energy segments such as photovoltaic power station projects, photovoltaic equipment manufacturers, new energy vehicles, etc. For example, it provides processing support for prefabricated steel sheets of photovoltaic storage tanks for the 950 MW photovoltaic photovoltaic composite power station project in Dubai; it provides supporting services for solar energy racks for foreign photovoltaic projects; it provides supporting services for polysilicon equipment and silane reactor equipment for famous new energy manufacturers; it provides supporting services for battery enclosures, battery tanks, battery cages, and other equipment for enterprises in the new energy vehicle industry chain. For the new energy automobile industry chain enterprises supporting battery box, vehicle body parts, charging pile equipment, etc., to achieve the coverage of the whole industry chain of upstream, midstream and downstream.