サービス事例:

強度のハイライト!堰き止める高性能堰き止める乗用車自動車高強度鋼加工への影響は着実に増加している(2023)

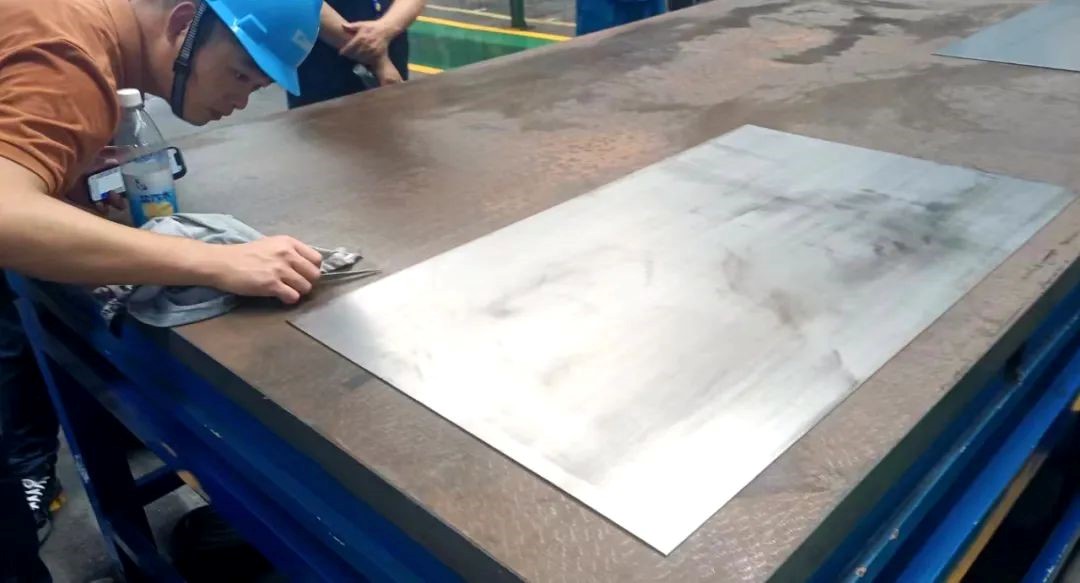

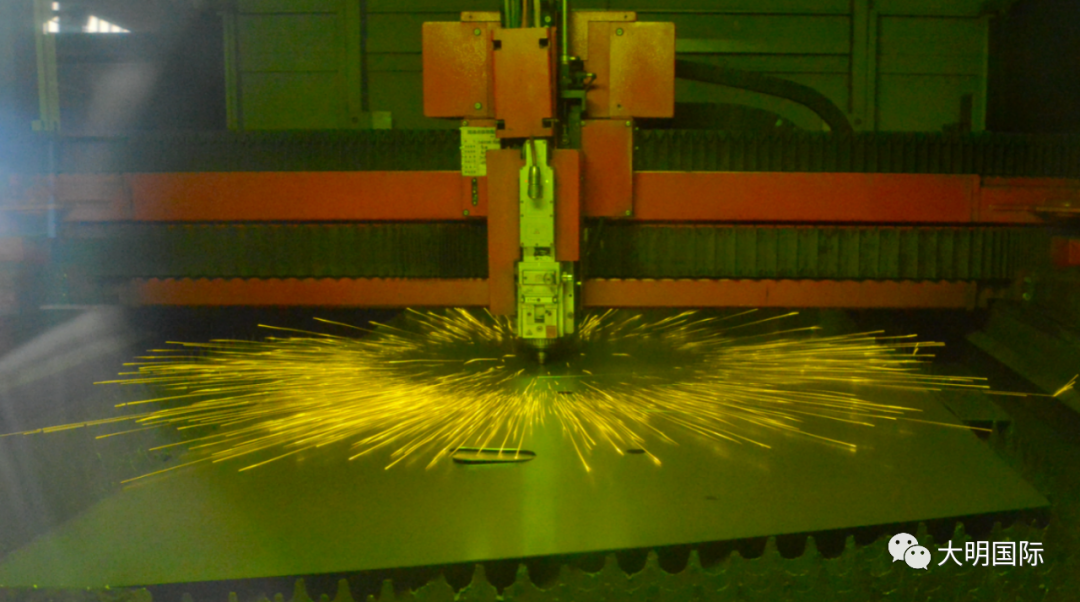

最近、大明無錫加工センターは厚さ1.6mmの自動車用マルテンサイト系高張力鋼HC1030/1300MSの加工に成功し、顧客から高い評価を得た。

この鋼材(Gipa鋼X-GPa)の速達堰き止め乗用車の実降伏強度は1,200MPaで、引張強度は1,400MPaに近く、自動車補強部品、衝突防止部品、安全部品、外装トリム補強部品、インナーサイドドアクラッシュバー、ドアシルプレートなどに使用できる。

軽量化 "だけでなく、強力な耐力と長寿命のビームや他の車体部品を確保するために、両方を行うにはどうすればよいのでしょうか?これは、ビーム鋼のような自動車鋼の処理に高い要件を提示します。

現在、大明高強度鋼、耐磨耗鋼加工「ハードコア」の強さはますます顕著になり、顧客の材料注文の問題を解決するだけでなく、長い材料注文サイクル、不十分な内部応力解放、低い材料歩留まりとその後の割れなどの顧客の悩みを解決するだけでなく、自動車鋼などの分野で大明鋼の影響力をさらに高めている。

自動車部品加工における利点

- 自動車排気システム用鋼の市場シェアは25%と高い。

- 自動車用マルテンサイト系高張力鋼HC1030/1300MSの加工を突破

- 圧延プロファイルやプレス部品などのサポートが追加され、機器の安全性が強化される。

70万台を出荷、江蘇大明が国際ハイエンド新エネ車プロジェクトを支援(2020年)

2020年上半期、江蘇大明はハイエンド電気自動車プロジェクトのために70万個の部品を加工し、週に4000個の入出荷需要があるため、工場は現在残業し、切断工程と包装を継続的に最適化している。

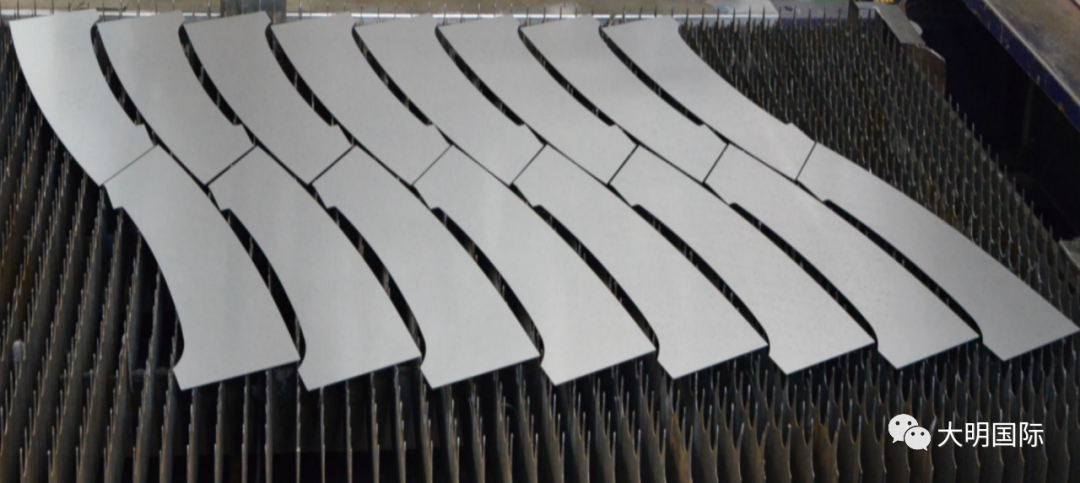

今回の製品はハイエンドの新エネルギー車の車体フレーム構造部品を支持するもので、江蘇大明が専門的で効率的な切断加工サービスを提供し、製品は9つの仕様があり、総量は数百万個に達する。製品は厚さ1.2-2mmの自動車用特殊鋼を使用し、江蘇大明が光ファイバー切断工程を経て切断加工した後、顧客はプレスなどの加工工程に入る。初期段階における広範な市場調査と審査、厳格な検査と相まって、お客様は江蘇大明のビジネス対応力、加工品質、生産管理レベルおよびサポートサービス能力に満足し、協力に至った。江蘇大明生産技術人員は前工程で、板形状、平坦度などの問題を解決し、加工品質と加工効率を向上させた。

年 江蘇大明ハイエンド新エネルギー自動車部品プロジェクト開始(年)

1月10日、江蘇大明は「高級新エネルギー自動車部品プロジェクト」の発布式を行い、江蘇大明の張峰総経理、金建東副総経理、営業、生産、品質管理、生産管理、物流各部門の責任者及び従業員代表が出席し、張峰総経理は動員演説を行った。

江蘇大明は専門的かつ効率的な切削加工サービスを提供し、製品は9つの仕様があり、総量は数百万個に達する。江蘇大明は特別プロジェクトチームを設置し、標準化された工程フローを策定し、金型と治具を最適化することで、生産能力を大幅に向上させ、顧客の需要に応じて大量生産できるようになった。このプロジェクトは2020年4月まで続く予定で、春節期間中も供給が保証される。

張峰総経理はスピーチの中で、このプロジェクトの意義と重要性を強調し、このプロジェクトを通じて、従業員の品質と技能、プロジェクトチームの運営レベル、処理品質と効率をさらに向上させ、最終的に会社の大型プロジェクトへの対応能力を高めることを期待した。彼は、技術、生産、物流などの各部門が緊密に協力し、支援サービスを成功裏に完了するよう求めた。

大明湖北加工センター絶妙な平鋼バッチ支持乗用車ビーム(2019年)

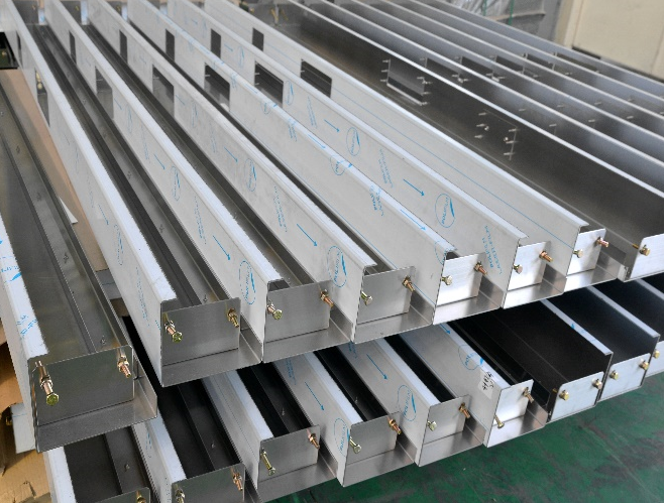

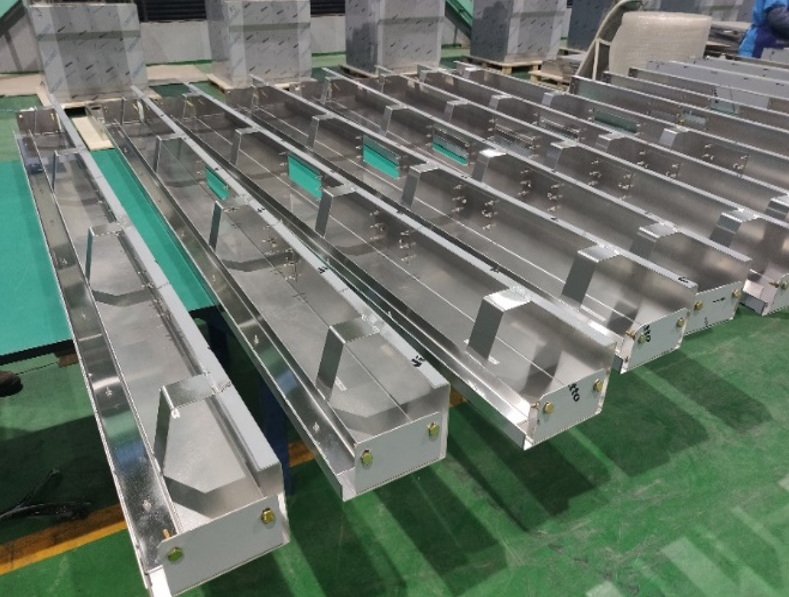

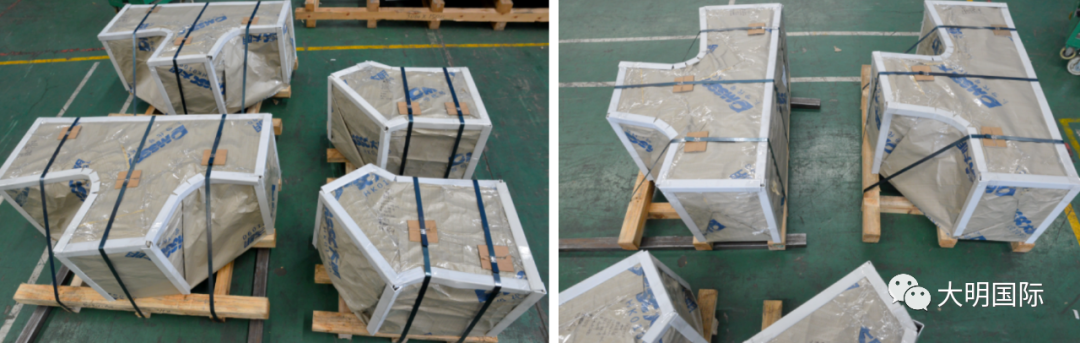

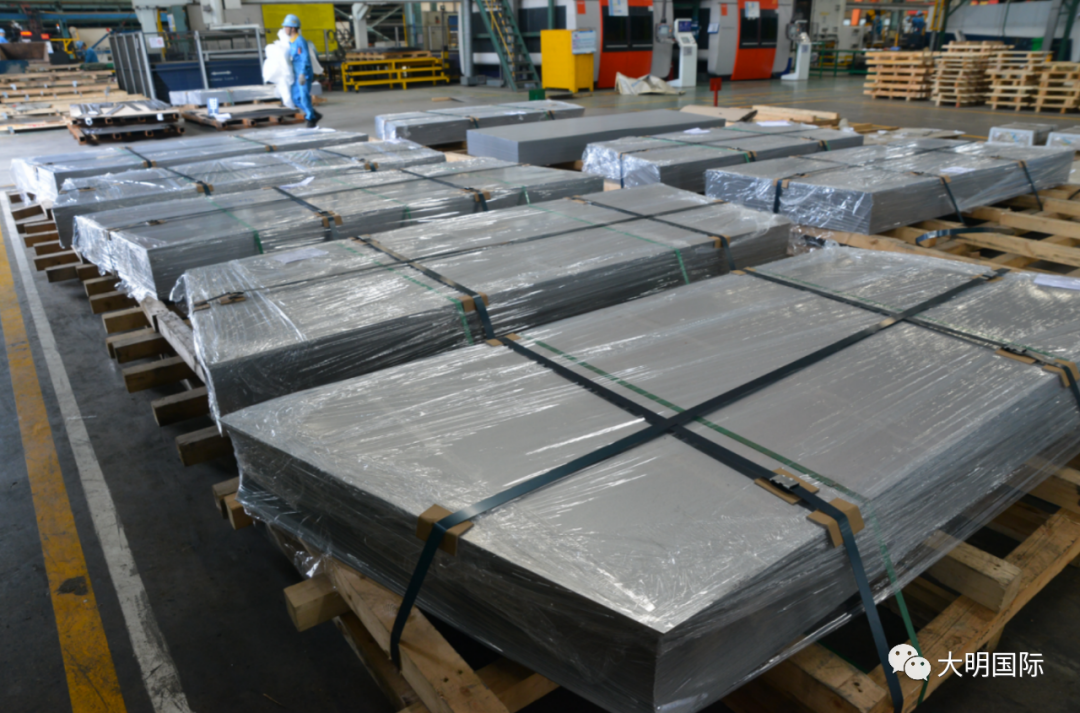

最近、大明湖北加工センターは自動車用梁平鋼の一括受注を受け、WL510 5.0/6.0*1500*C自動車用梁平鋼コイルを5*312.5*1180と6*207*760平鋼に加工する必要があり、大型乗用車工場とマッチングして、自動車のメインビームとして使用される。大明湖北大明加工センターは高強度鋼の平鋼ラインを使って、お客様に高品質、高精度の平鋼製品を提供し、完成した製品も精緻な防湿紙で包装する。大明湖北加工センター平鋼製品は、顧客の生産効率を向上させるだけでなく、顧客が製品の品質を向上させるのに役立つだけでなく、顧客は良いレビューを与え、それは長期的かつ安定的な協力になると述べた。

精巧な平鋼製品

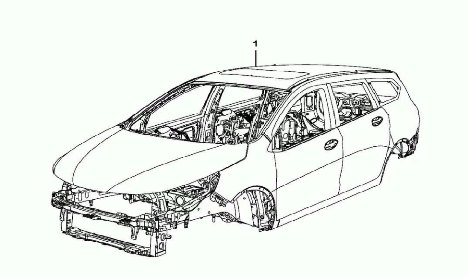

乗用車フレーム・ビームの模式図