Daming International Expands Strategic Partnership with CLK Worldwide and Zhenxin International

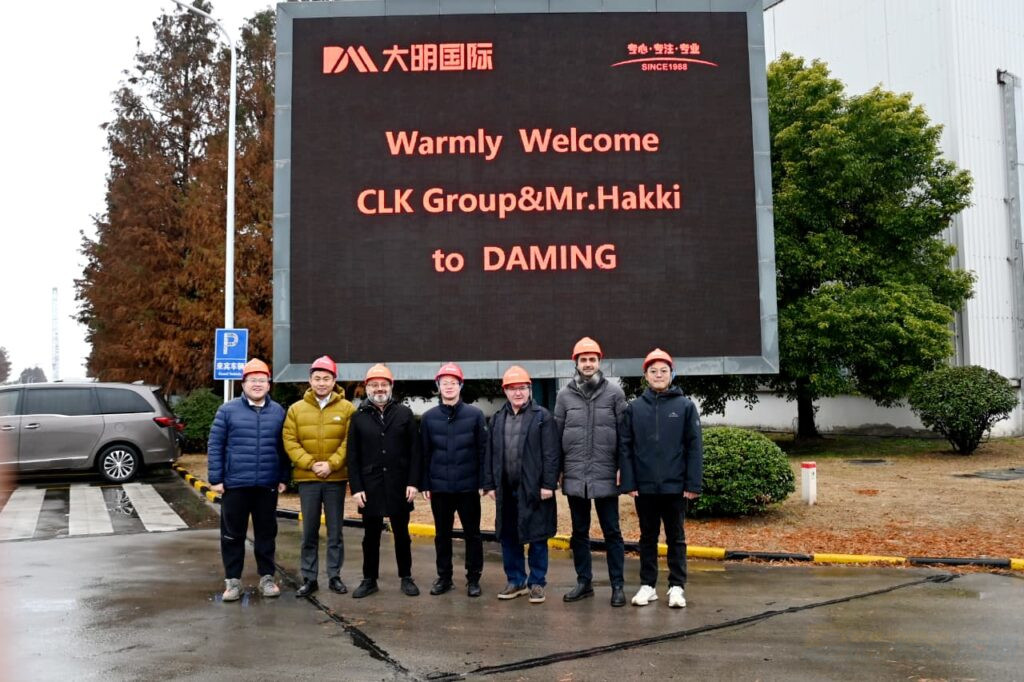

Daming International, a key player in steel material supply, steel processing, and parts and component fabrication for the mining sector, recently welcomed a delegation from CLK Worldwide and Zhenxin International. Led by Mr. Yahya GM and Mr. Okan, Purchasing Director of CLK Worldwide, along with Mr. Hakki Caglar, Managing Director of Zhenxin International, the visit aimed to strengthen ongoing collaborations and explore new opportunities in the mining industry. The meeting took place at Daming’s headquarters, where Mr. Yin Baozhu, Assistant General Manager of Daming International Import & Export, and Mr. Zheng Tao, Department Head, hosted the visiting team. The discussion focused on the increasing demand for high-strength, wear-resistant steel—an essential […]

Daming: Setting the Standard in High-Strength Steel Manufacturing

Hubei Daming, a leading name in high-strength steel processing, has once again proven its technical expertise and manufacturing prowess with the delivery of key structural components for a major domestic dump truck manufacturer. This achievement not only highlights Daming’s technical capabilities but also reinforces its ability to meet the tough demands of producing large, complex, and high-strength components crucial to the heavy truck industry. Meeting the Demands of High-Strength Structural Components The latest project saw Daming manufacturing vital bending components from high-strength steel, known for its durability and ability to withstand extreme conditions. These parts, which had a plate thickness of 6mm and lengths of 10-11 meters, needed to […]

Jingjiang Daming’s Breakthrough in Reducing Cutting Stress of High-Strength Steel

Jingjiang Daming, one of Daming’s eleven steel processing centers, has achieved a major breakthrough in improving the cutting stress of high-strength steel, through a comprehensive initiative aimed at optimizing the precision and efficiency of its steel fabrication processes. By focusing on stress control, parameter standardization, and real-time data sharing, this initiative has significantly advanced the company’s ability to produce high-quality steel products with greater consistency, reducing rework and boosting overall production performance. The initiative, executed at the company’s VIGANO237 unit, has resulted in improved cutting quality, enhanced fabrication capabilities, and a more streamlined production workflow — paving the way for future advancements in steel manufacturing. Precise Stress Control for Enhanced Steel […]

Hubei Daming Delivers Millimeter-Level Precision in Bridge Steel Components

Recently, Hubei Daming, one of Daming International’s eleven steel processing centers, completed a demanding fabrication project for a renowned bridge construction company. Through advanced processing technology, high-end equipment, and exceptional teamwork, Hubei Daming overcame multiple precision manufacturing challenges — ensuring the flawless delivery of several critical bending structural components that form the “steel bones” of large-scale bridges. This achievement once again demonstrates Daming’s strength in high-end metal component processing and its unwavering commitment to empowering national infrastructure with intelligent manufacturing excellence. Precision at the Millimeter Level: Tailoring the Bridge’s Structural Skeleton The project involved low-alloy, high-strength steel components with thicknesses of 8 mm and lengths ranging from 5 to […]

Daming Strengthens Strategic Cooperation with HBIS

A senior delegation from Daming International Holdings Limited, led by Chairman Zhou Keming, visited HBIS Group, one of China’s largest and most influential steel producers, to explore deeper collaboration in high-end steel processing, product development, and supply chain integration. The delegation included President Liang Zongren, Assistant to the President Zhang Jun, Group Technical Director Wang Xiaojian, Carbon Steel Division General Manager Jiang Suiqiang, Shandong Daming General Manager Chen Jianming, Tianjin Daming General Manager Hu Qiang, and Deputy Director of Group Supply Department Shi Feng. The Daming delegation was warmly received by HBIS Party Secretary and Chairman Liu Jian, along with HBIS Deputy General Manager Zhu Tanhua, HBIS Sales Party Secretary […]

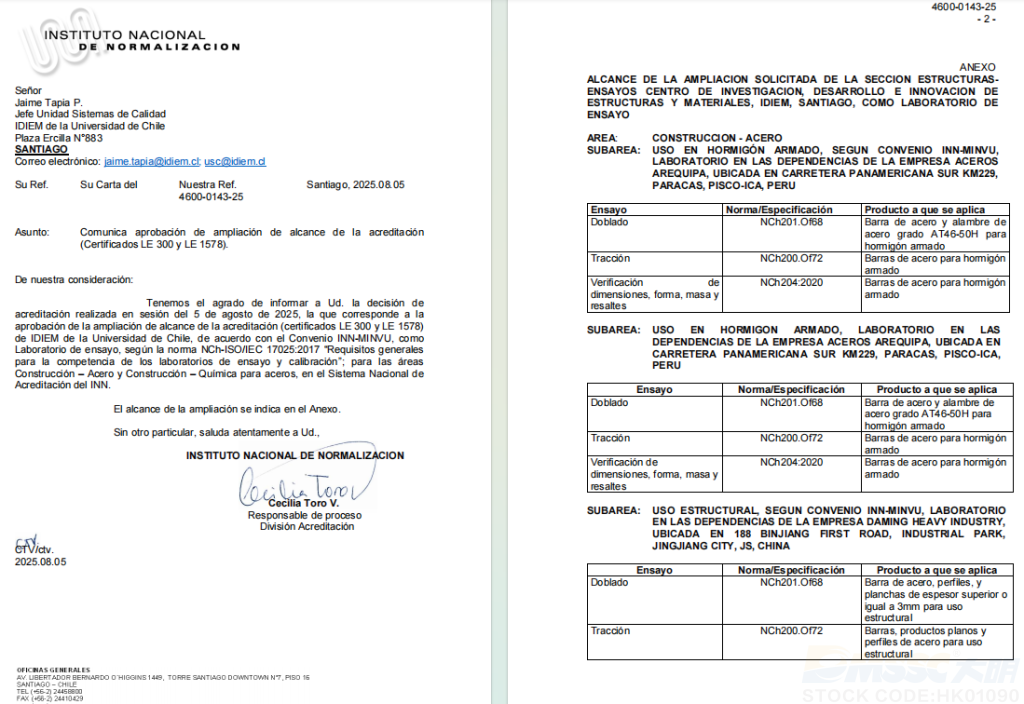

Daming Heavy Industry Secures China’s First Chilean NCh203 Material Testing Accreditation

In a major leap forward for China’s materials testing industry, Daming Heavy Industry has officially been accredited by the Chilean National Standards Committee, becoming the first and only laboratory in China authorized to conduct NCh203 material testing. This milestone marks not only a breakthrough for Daming but also China’s first international accreditation in this field, positioning the company as a global leader in materials testing. A Critical Step Toward Global Mining Supply Chains The NCh203 certification is a cornerstone standard for the mining and metallurgical sectors in Chile, one of the world’s largest mineral exporters. It covers essential performance indicators such as tensile strength and corrosion resistance for metal materials—key metrics for qualifying suppliers in mining […]

ダミングのカット・トゥ・レングス:高強度鋼の真の強さを発揮させる

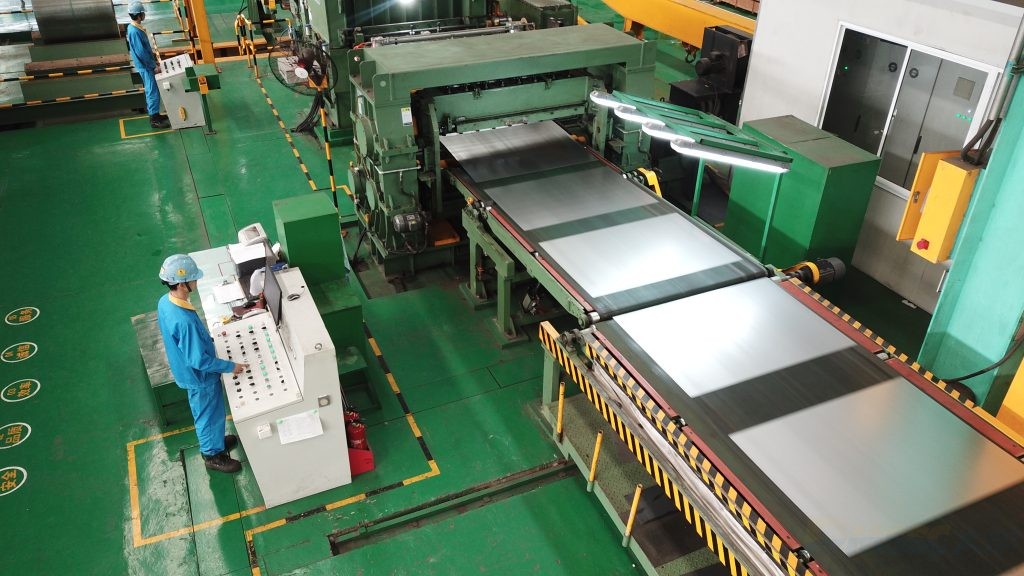

Cut to length (CTL), refers to a processing technology that processes metal coils into flat plates of the required length through uncoiling, leveling, sizing, and shearing, and then stacks them neatly. This year marks the 36th anniversary of Daming’s establishment and the 12th year of its carbon steel business. Over the years, Daming’s carbon steel business has achieved rapid growth. Among them, the cut to length, although only one of the most advanced simple processing technologies for metal materials, is the most basic business shows the most real skills! At present, the carbon steel cut-to-length production lines of Daming’s ten processing centers are all world-leading and ultra-high-strength such as FIMI, NOVA, and […]

高強度鋼と耐摩耗鋼において、なぜDamingがより有利なのか?

バルク材料価格が高騰し、エネルギー消費の二重管理政策が強化される中、大明は川上のトップ製鋼所と協力し、高強度鋼、耐摩耗鋼などの高品質資源を提供している。大明は「顧客中心」のサービスを堅持し、鉱山機械、エンジニアリング機械、特殊車両、セメント、固形廃棄物処理などの業界の市場を絶えず拡大し、耐摩耗加工を絶えず改善し、加工技術をアップグレードし、サービス能力をさらに向上させ、ユーザー体験を向上させる。加工設備と加工能力のアップグレード 大明の加工プラットフォームは、複数の手段、強力な能力、高い加工効率、低い総合コストを持っています。耐磨耗鋼、高強度鋼の表面処理、切断、曲げ、円、溝、溶接、機械加工などの加工を行うことができる。

大明が高強度耐摩耗鋼の差別化サービスブランドを確立するまで

より高く、より強く、より良く!