Daming Heavy Industry Expands Global Reach with Customized 260-Ton Mining Truck Bodies

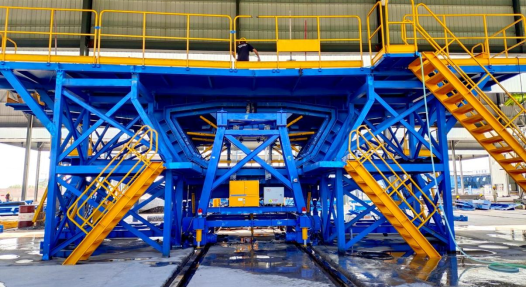

Daming Heavy Industry has completed the production and shipment of a batch of 260-ton mining truck bodies to key international markets, including South Africa, Australia, and Papua New Guinea. These units, customized for large-scale copper, gold, and silver mining projects, were shipped from the company’s Yangtze River Terminal, highlighting Daming’s capability to handle complex, high-volume manufacturing and global logistics. The mining truck bodies are designed to meet the specific needs of open-pit mining operations, where the demand for durable, high-capacity equipment is critical. These trucks will be used for transporting heavy materials over long distances, ensuring that mining projects can run smoothly in remote, high-demand environments. Overcoming Delivery Challenges with […]

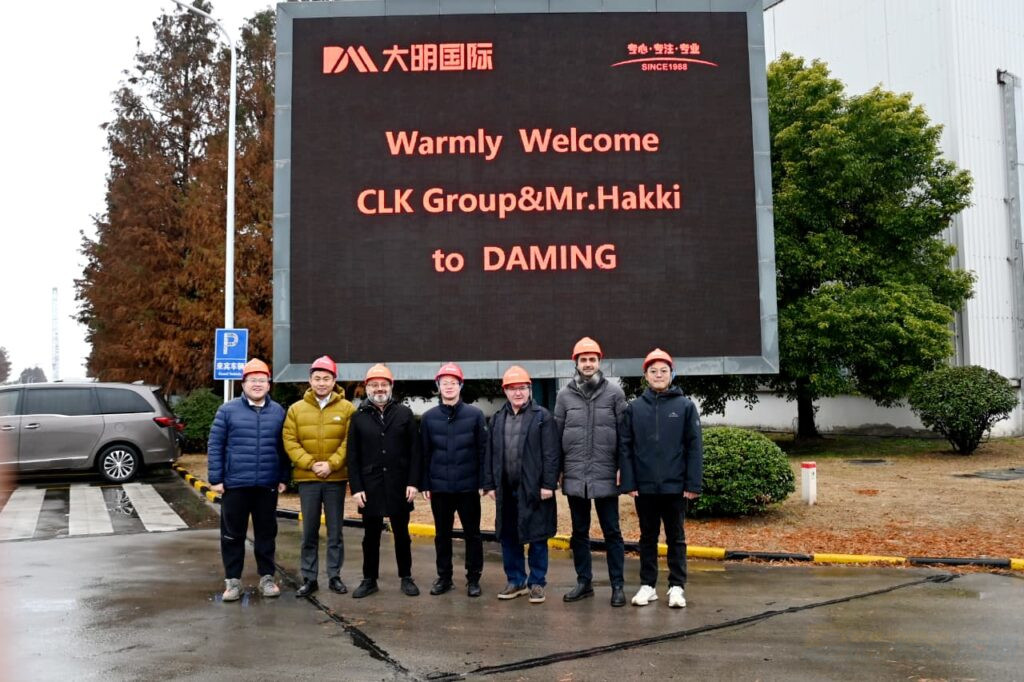

Daming International Expands Strategic Partnership with CLK Worldwide and Zhenxin International

Daming International, a key player in steel material supply, steel processing, and parts and component fabrication for the mining sector, recently welcomed a delegation from CLK Worldwide and Zhenxin International. Led by Mr. Yahya GM and Mr. Okan, Purchasing Director of CLK Worldwide, along with Mr. Hakki Caglar, Managing Director of Zhenxin International, the visit aimed to strengthen ongoing collaborations and explore new opportunities in the mining industry. The meeting took place at Daming’s headquarters, where Mr. Yin Baozhu, Assistant General Manager of Daming International Import & Export, and Mr. Zheng Tao, Department Head, hosted the visiting team. The discussion focused on the increasing demand for high-strength, wear-resistant steel—an essential […]

Ma Rui’s Journey of Growth at Daming Cut-to-Length Workshop

At Daming, growth is not just a company goal — it’s a deeply personal journey for each employee. Across departments, stories of hard work, challenges, and triumphs paint a rich picture of the transformation that happens when individuals commit themselves to both their craft and their team. Ma Rui’s story, in particular, is one of dedication and evolution, from a nervous newcomer to a skilled team leader in Daming’s cut-to-length workshop. From Uncertainty to Expertise When Ma Rui first joined the team at Daming eight years ago, the cut-to-length workshop felt like an intimidating place. The hum of heavy machinery, the complexity of the equipment, and the precision required to […]

Daming Delivers High-End Stainless Steel Plates to Malaysia

Wuxi Daming, one of Daming’s eleven processing centers, has completed a new export project as part of its ongoing international business development, delivering more than 200 tons of precision-processed flat stainless steel products to a high-end manufacturing equipment project in Malaysia. The shipment was completed on schedule and supports the company’s business targets for 2026. The order involved the processing of 316L stainless steel, a material widely used in demanding environments due to its strong corrosion resistance and high-temperature performance. More than 13,000 pieces of plates of various specifications were produced, each measuring 0.7 mm in thickness and 1,800 mm in length. Given the application in high-end equipment manufacturing, the […]

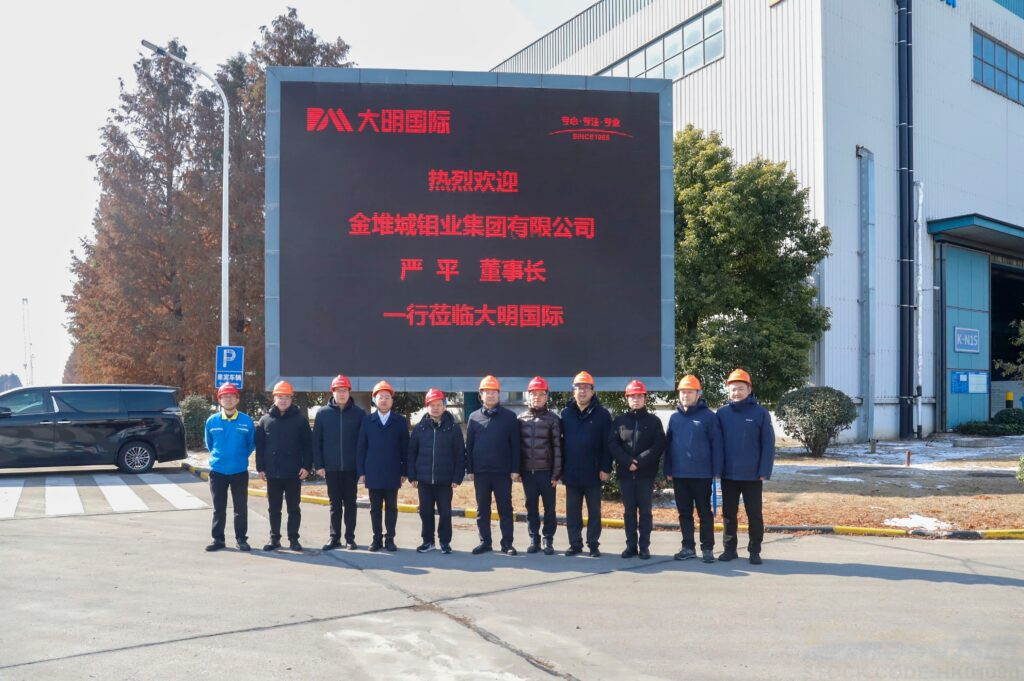

Jinduicheng Molybdenum Chairman Yan Ping Visits Daming to Explore Collaboration Opportunities

On January 21, Yan Ping, Chairman of Jinduicheng Molybdenum Co., Ltd., led a delegation to Daming. The group included Wang Jiyu, Deputy General Manager of the listed company; Zhao Meng, Deputy General Manager of the trading company; Wang Hairong, Deputy General Manager of the metal division; Li Hongbo, Manager of the Refractory Materials Sales Department; and Wang Boshi, Business Manager. They were warmly welcomed by Liang Zongren, President of Daming International; Qian Li, Executive Vice President; Luo Zhihui, Executive Vice President of Daming Heavy Industry; and Wang Xi, General Manager of Energy Equipment at Daming Heavy Industry. The visit included a tour of Daming’s facilities and in-depth discussions on potential […]

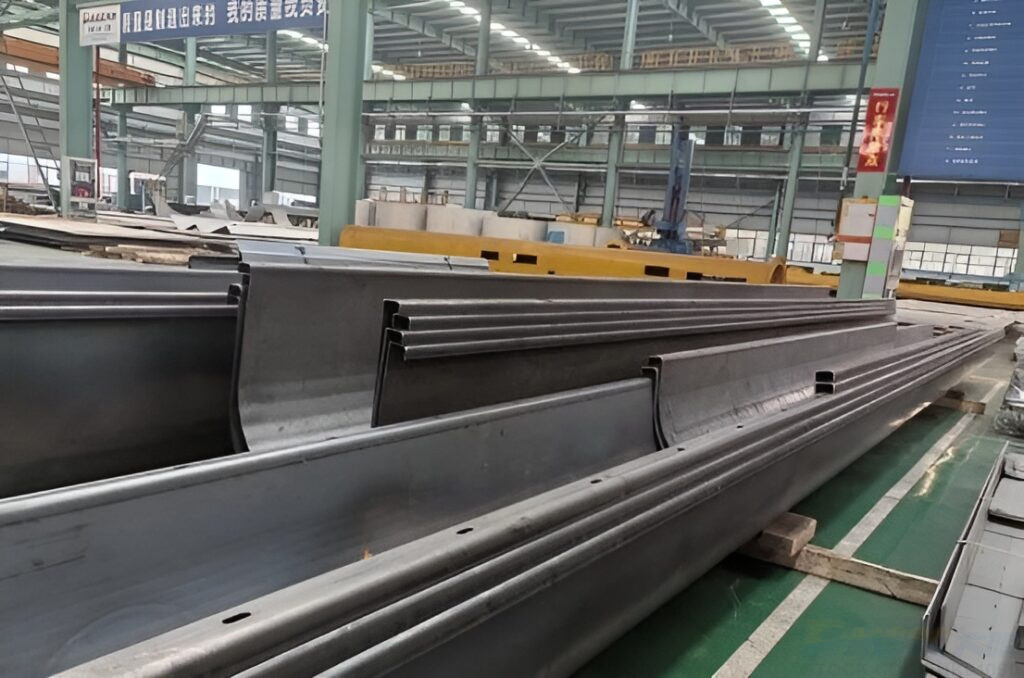

Hubei Daming Precision Sheet Metal Processing

As global equipment manufacturing continues to evolve toward larger structures, higher strength materials, and tighter tolerances, precision sheet metal processing has become a critical foundation for product reliability and performance. At Hubei Daming, one of Daming’s eleven processing centers, the broad industry experience, advanced forming capabilities, and systematic process control in Precision Sheet Metal Processing enable us to support demanding export equipment projects with confidence and consistency. Meeting the Challenges of Large-Scale Sheet Metal Forming Large-format carbon steel components present unique manufacturing challenges. Issues such as welding deformation, stress concentration during forming, and dimensional instability in ultra-wide plates can directly impact assembly accuracy and long-term structural performance. For curved and […]

Shandong Daming Delivers Customized Papermaking Equipment with Precision and Expertise

Shandong Daming has recently completed the production and full assembly of a custom-designed 304L stainless steel pressure screens for a prominent client in the papermaking industry. After a thorough on-site inspection, the client expressed strong satisfaction with the equipment’s performance, processing quality, and Daming’s technical expertise—laying the groundwork for future partnerships. Pressure scree is a crucial component of the papermaking process, playing a pivotal role in maintaining the stability and efficiency of the production line. In papermaking, where consistency and high output are vital, every piece of equipment must operate at peak performance. To meet the specific needs of this client, Daming chose 304L stainless steel—a material known for its […]

Hubei Daming Supports Russia’s First High-Speed Rail Project with Precision Manufacturing

Hubei Daming, one of Dmaing’s elven steel processong centers, has completed a major order for Russia’s first high-speed rail line, marking a significant milestone in international cooperation and infrastructure development. The company partnered with a leading domestic manufacturer to provide precision materials for this critical project, earning high praise from the client. A Key Project for Regional Connectivity The high-speed rail line, stretching from St. Petersburg to Vladivostok, is part of Russia’s long-term plan to enhance connectivity across its vast territory, particularly in the Far East. With Russia’s vast land area and growing need for modern transportation, this project represents a significant investment in both infrastructure and regional development. As […]

How Daming Cut-to-Length Supports Automotive Parts Manufacturing with Precision and Reliability

In today’s automotive industry, every component starts with the right material. For automotive parts manufacturers, carbon steel flat plates are widely used in body structures, chassis systems, safety components, and various brackets. Before these materials reach the production line, one essential process plays a key role in quality, efficiency, and cost control—cut-to-length processing. Cut-to-Length: Where Precision Begins Cut-to-length refers to the process of uncoiling, leveling, and cutting steel coils into flat sheets with precise dimensions using dedicated production lines. While it may seem like a basic step, for automotive manufacturers it directly affects downstream performance. At Daming, cut-to-length is not just about cutting steel—it is about delivering materials that are […]

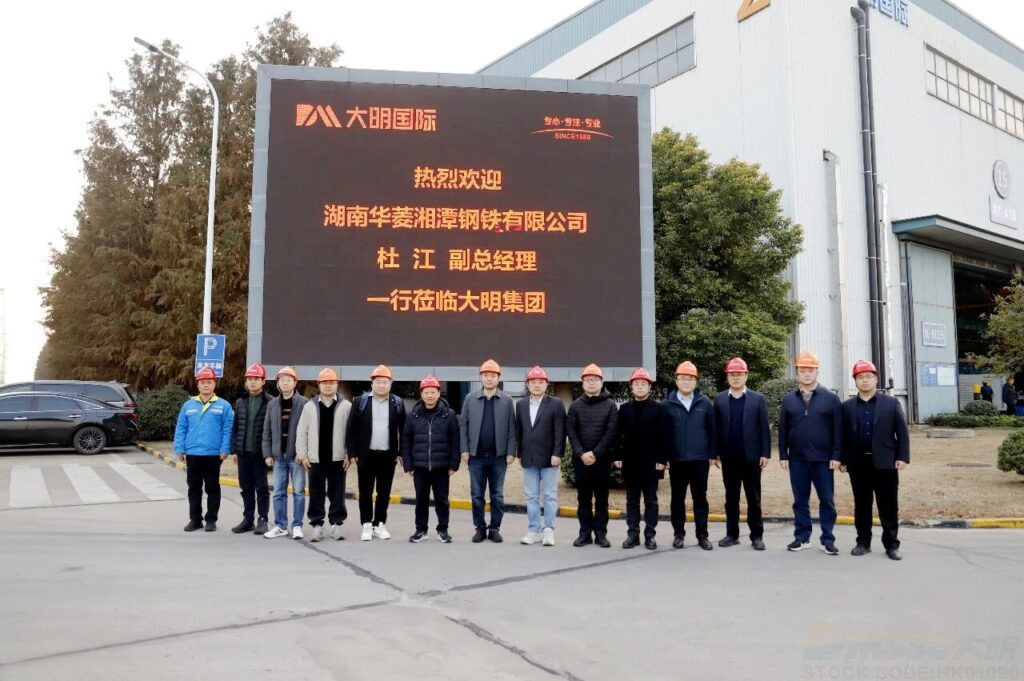

Delegation from Hunan Valin Xiangtan Iron & Steel Visits Daming

On January 13, a delegation from Hunan Valin Xiangtan Iron & Steel Co., Ltd., led by Du Jiang, Deputy General Manager, paid a visit to Daming International for exchange and discussions. The delegation included Zheng Jian, Deputy Director of the Science and Technology Quality Inspection Department; Xiao Lingyun, Deputy Director of the Sales Department; Zhang Wenqing, General Manager; and Wang Jiming, IPD Manager of the Engineering Machinery Steel Project Team. The guests were warmly received by Zhou Keming, Chairman of Daming International, together with Liang Zongren, President; Yang Shun, General Manager of Xiehao Supply Chain and Deputy General Manager of the Group’s Carbon Steel Business Unit; Wang Xi, General Manager […]