Daming Commercial vehicle beam steel processing services:

Bending Beams; Bending Auxiliary Beams; High Strength Beam Flat Steel; Rolled Beams; Rolled Profile Auxiliary Beams; Advantages: end quality, flatness, good cut; straightness, good internal stress control.

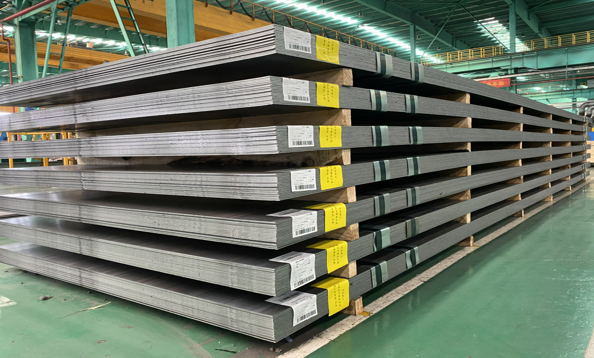

Daming fine quality four cut edge plate:

HSC Handan 450TP (yield strength 1000 MPa) Differentiated service capability : no cracking in bending, no warping in cutting.

Granskning av fall:

Daming Hubei processing center supporting automobile seat frame and livestock special vehicle beams

Beam steel service for Guangzhou auto parts enterprises

Recently, an automotive parts company, after market investigation, highly recognized the comprehensive ability of Daming Hubei processing center in terms of raw material guarantee, quality of processed products, logistics one-stop service, etc., and quickly chose Hubei machining center for supporting product processing.

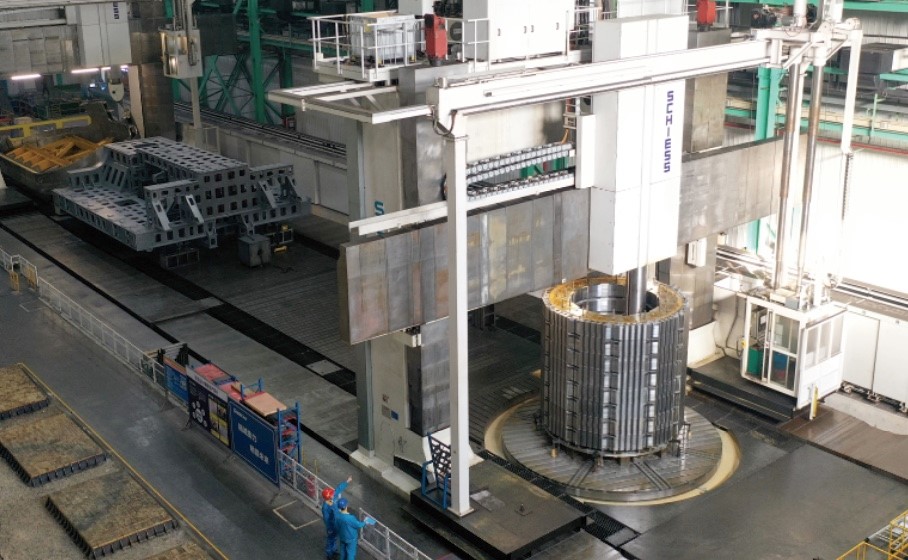

The processed product is beam steel, 10mm thick, processing length of 3000mm, the product is processed in Hubei machining center of Italy VIGANOCTL20 unit processing, the equipment specializes in processing and processing of high-strength steel and hot-rolled stainless steel, the length accuracy control in ± 1.0mm, diagonal accuracy ± 3.0mm / 6m.

Hubei machining center in a very short period of time to complete the processing and long-distance shipping arrived, the customer on the hardness of the material, tensile strength, finished straightness, geometry, flatness, surface treatment and other aspects of the inspection, fully affirmed the quality of the product.

Fallgranskning:

One-stop processing service for pastoral specialties

Hubei Daming has been entrusted to produce a batch of secondary beam bending parts for a customer of special-purpose vehicle for animal husbandry industry, and all of them have been accepted and put into use at present.

According to the model supporting the total length of processing parts ranging from 10-12m, the length and width ratio of the cut parts is large and the bending coefficient of difficulty is high, the customer has repeatedly used welding and bending and then secondary processing and other process improvements are unable to meet the load-bearing requirements, and after inquiring to Daming Hubei machining center. This batch of processed parts are all made of WL700 high-strength beam steel produced by WISCO, involving the process of sizing and leveling, laser cutting, bending. Cutting process using Italian VIGANO CTL20 leveling equipment, stress release is more complete, the cutting process is not easy to deform; cutting process using Japan Tanaka FMRII40-TF6000 fiber laser cutting machine, excellent cutting parameters can effectively control the deformation of the cut pieces and sickle bend; bending process using Hubei Sannhuan 2-PPEB500/41-5 dual machine The bending process adopts Hubei SANHUAN 2-PPEB500/41-5 double machine linkage and PPEB-H 2000/125 heavy-duty bending special two sets of equipment combination bending, not only to ensure the stability and consistency of the finished product size, but also to provide customers with one-stop convenient processing services, by the customer side of the high degree of recognition.

Granskning av fall:

Daming Wuxi machining center successfully completed the processing of a batch of 1.6mm thick automotive martensitic high strength steel HC1030/1300MS, which won full recognition from the customer.

The actual yield strength of this steel grade (Gipa steel X-GPa) is 1200MPa, and the tensile strength is close to 1400MPa, which can be used for automotive reinforcing parts, collision prevention parts, safety parts and exterior trim reinforcing parts, inner side door impact bars and door sill plates, and so on.

How to do both “lightweight”, but also to ensure that the beams and other body components of the strong bearing capacity and long service life? This places high demands on the processing of automotive steel such as beam steel.

At present, relying on the “high-quality material supply (joint steel mills) + customized processing (combined with process requirements) + JIT logistics” full-process service model, Daming high-strength steel, wear-resistant steel processing “hard core” strength is becoming more and more prominent, not only for the customer to solve the problem of material ordering This not only solves the pain points such as long material ordering cycle, insufficient internal stress release, low material yield and subsequent cracking for customers, but also further enhances Daming’s influence in the field of automotive steel.

At present, the commercial vehicle enterprises served by Daming have covered XCMG, Dongfeng, Sany Group, Zoomlion, China CNR, China National Heavy Duty Truck, Shaanxi Automobile Heavy Duty Truck, Yutong Commercial Vehicle, Jianghuai Automobile, Jiangling Automobile, Beiqi Foton, CIMC, Yuchai Dongte, Henan Juntong, Hongchang Tianma, Shiyan Chitian, Anhui Xingma, Chengli Specialized Vehicle, Shandong Yangjia, Qingtai Group, etc. Daming will continue to strengthen the linkage function and provide customers with one-stop convenient processing service.

Daming will also continue to strengthen the link function, promote the establishment of steel mills, research institutions, associations and end-users to interact with the channel, and ultimately, together with partners, strive to create the strongest ecosystem of high-strength steel, wear-resistant steel supporting the Chinese commercial vehicles, and continue to promote the industry to lightweight, high-end.