Table of Contents

1 Stainless steel manufacturing process

1.1 Raw materials

1.2 Dissolution.

1.3 Extraction

1.3.1 AOD (Argon Oxygen Decarbonization)

1.3.2 Vacuum decarburization (VOD)

1.3.3 ESR (Electroslag Remelting)

1.3.4 Vacuum arc remelting (VAR)

1.4 Continuous casting

1.5 Rolling and surface treatment

2 Stainless steel with special metal treatment, tempering and surface polishing

1. Stainless steel manufacturing process

Stainless steel is used in a wide variety of applications, from household spoons and forks to medical devices and airplane parts, and the general flow of the manufacturing process is shown below. (This article is based on the process of an electric furnace manufacturer).

We have raw materials in sizes ranging from 1-3 mm in thickness, and offer user-friendly sizes and quantities through cold rolling and other processing.

Let’s take a closer look at each of these processes.

1.1 Raw materials

Stainless steel (for example 403 stainless steel production) is a general term for steel that has a certain chemical stability in air, water, acids, alkalis, salts or other corrosive media. Special steel with excellent properties such as corrosion resistance, heat resistance, low temperature resistance. Stainless steel corrosion resistance is mainly due to the addition of chromium, under the action of corrosive media, the surface of the steel parts will form a layer of solid dense oxide film, called “passivation film”. This film makes the metal isolated from the outside world, preventing the metal from being further corrosion, and also has the ability to self-repair, once destroyed, the chromium in the steel will be with the oxygen in the medium to regenerate the passivation film, continue to play a protective role. Stainless steel in addition to adding a higher content of chromium, but also match the addition of nickel, molybdenum, manganese, nitrogen and other alloying elements, so that the steel can also obtain sufficient strength, plasticity and toughness, as well as good process properties, such as weldability, processing and molding.

1.2 Dissolution

Ferroalloys (ferroalloys such as ferrochrome and ferronickel) are used as raw materials for the production of stainless steel by melting and refining ores in electric furnaces as well as recycled materials – stainless steel scrap.

These ferroalloys and stainless steel scrap are melted in an electric furnace.

These furnaces use arc heat to melt metals at temperatures from 3000°C to 3500°C. The furnaces are designed to be used in a wide variety of applications.

1.3 Extraction

After melting, a process called refining is required to remove impurities and carbon.

The following AOD and VOD methods are typical of stainless steel refining methods.

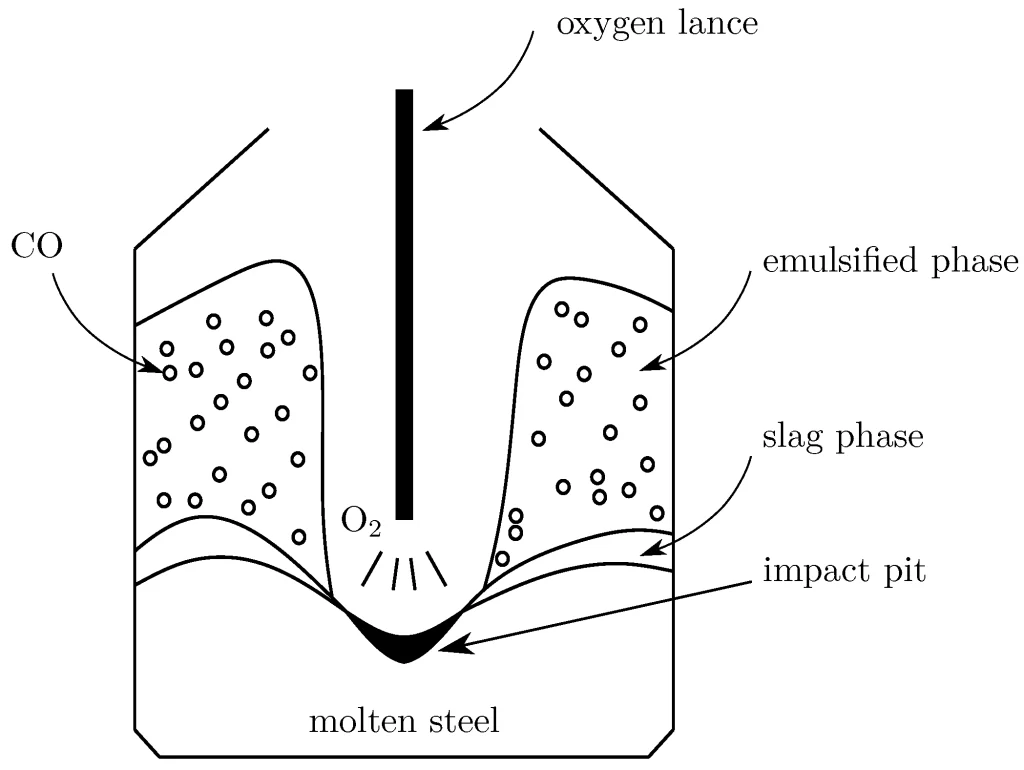

AOD (Argon Oxygen Decarbonization Process)

This is a stainless steel refining process, the main features of which are the possibility of blending high carbon ferrochrome to improve chromium recovery, very low carbon content and reduced impurities. After the raw material is melted in an electric furnace, the molten metal is transferred to a separate refining vessel and decarbonized by blowing an argon and oxygen gas mixture from the bottom of the furnace. This refines the metal with extremely low carbon content while suppressing oxidative loss of chromium.

1.4 VOD (Vacuum Oxygen Decarbonization Process)

This method is similar in characteristics to AOD, but the ladle is decarburized in a vacuum tank by blowing oxygen under vacuum through a top-blowing lance. Although not as good as AOD for large-scale production, the vacuum effect makes it suitable for producing high-purity stainless steels with very low levels of carbon, nitrogen, and hydrogen. After refining, re-melting processes, such as ESR and VAR below, can be performed to further improve cleanliness (removal of impurities).

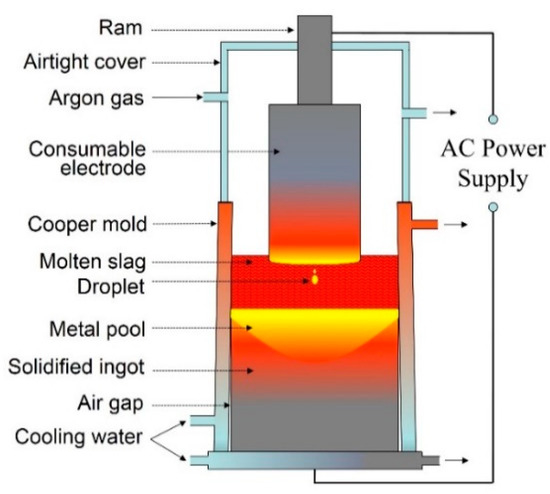

1.5 ESR (Electroslag Remelting)

The vulnerable electrode is melted under the resistance heat of slag and solidified in water-cooled copper mold. Due to the refining effect of slag, the vulnerable electrode has the characteristics of desulfurization, deoxidation and reduction of inclusions, etc. The ingot is intact, with less segregation, clean ingot skin, and no skinning in hot working.

1.6 Vacuum Arc Remelting (VAR)

The material is melted by DC arc in vacuum or inert gas using consumable electrodes and solidified in a water-cooled copper mold, resulting in a finished ingot with a well-solidified structure and very few refractory impurities and inclusions.

As consumable electrodes, these components are pre-treated in separate furnaces (atmospheric pressure furnaces or vacuum induction furnaces) and then cast in the form of electrodes.

1.7 Continuous casting

A casting method in which molten metal is placed into an open-bottomed mold for an extended period of time and the material is withdrawn from the bottom. Continuous casting is possible. Compared to the block-and-block method (in which molten metal is poured into a casting mold, hardened, reheated, rolled, and cut to specified lengths), which was the dominant method in the past, continuous casting offers many advantages, such as increased productivity and lower costs due to the omission of processes; and improved quality, such as a more homogeneous microstructure and fewer non-metallic inclusions. The advantages include, in terms of quality, a more homogeneous structure and fewer non-metallic inclusions.

1.8 Rolling and surface treatment

Rolling is the process of sandwiching the material between two rails and then stretching it into a thin layer with pressure, through which the material becomes stainless steel.

There are two main types of rolling: hot rolling and cold rolling.

Hot rolling is a method of processing at elevated temperatures between 900°C and 1200°C. It is a method of rolling that is used to produce a wide range of products. Hot rolling has low deformation resistance and good processing performance, but compared with cold rolling, hot rolling has lower dimensional accuracy and poorer surface finish.

Cold rolling is a rolling process that takes place at room temperature and is not as good as hot rolling in terms of workability, but has high dimensional accuracy and a smooth, bright surface. Hot rolling is followed by cold rolling for finishing with higher accuracy or, depending on the application, only hot rolling can be used to produce the product as is.

In this process, the surface is also treated by polishing or bright annealing to achieve the desired luster. Stainless steel treated by us, tempered, surface polished. Our company performs cold rolling and surface finishing in the above process. We offer the following products Stainless steel type, Available Tempering Surface treatment Surface Finishes For more information on these products, Check Our Product pages.