Daming ma doświadczenie w przetwarzaniu i wspieraniu sprzętu morskiego, opierając się na bogatym zespole produkcyjnym i serwisowym, a następnie na sprzedaży, technologii, produkcji, jakości i innych zespołach współpracy wielostronnej. Obecnie Daming dostarcza wysokiej jakości pakiety dla klientów z branży morskiej, takie jak wewnętrzne grodzie chemikaliowców, największa morska instalacja wiatrowa, solidna rama palowa (skrzynia biegów), morskie wieże płuczkowe, morskie zbiorniki paliwa i tak dalej.

Przegląd przypadku:

Wieża płuczkowa dla statków Yara Marine Technology (YMT)

15 stycznia 2019 r. firma Daming Heavy Industries (DHI) z powodzeniem dostarczyła pierwszy zestaw morskich wież płuczkowych wspierających YMT, a dostawa ta jest ważnym kamieniem milowym dla DHI w zakresie usług przetwarzania morskich wież płuczkowych.

YMT jest działającym globalnie, zintegrowanym dostawcą usług odsiarczania i odazotowania (FGD) z ponad milionem godzin niezawodnej pracy dla ponad stu armatorów na całym świecie. W dziedzinie morskich płuczek odsiarczających YMT zawsze miało dominującą przewagę i wiodącą pozycję technologiczną na rynku.

Jako główny sprzęt ochrony środowiska w dziedzinie żeglugi morskiej, morska wieża odsiarczająca wykonana jest z wysokiej jakości stopu na bazie niklu, którego produkcja jest trudna i ryzykowna. Daming Heavy Industry pokonał wiele trudności technicznych podczas procesu produkcyjnego, takich jak odkształcenia spawalnicze, cienkościenne połączenia cylindrów są łatwe do odkształcenia itp. Dzięki wspólnym wysiłkom wszystkich członków projektu oraz walce dzień i noc, pierwszy zestaw wieży płuczkowej został dostarczony miesiąc przed terminem.

Przedstawiciele klienta i armatora wysoko ocenili wydajność i profesjonalizm Daiming Heavy Industry i wyrazili silną wolę długoterminowej współpracy. Obecnie, kolejne produkty o dużej objętości są produkowane w sposób uporządkowany w warsztacie Daming Heavy Industry.

Przegląd przypadków:

Pomyślna dostawa największego na świecie i pierwszego w Chinach statku do instalacji morskich elektrowni wiatrowych N966 w ramach projektu stałej ramy palowej

Daming z powodzeniem dostarczył największą na świecie ramę stałego pala (skrzynię przekładniową) do Qidong COSCO Shipping Offshore Engineering Co., Ltd., co oznacza udane wejście Daming na pole produkcji dużych mechanicznych części konstrukcyjnych wykorzystywanych w morskich statkach instalacyjnych energii wiatrowej.

Projekt statku do instalacji turbin wiatrowych typu jack-up N966 europejskiego armatora zbudowany przez Qidong COSCO został specjalnie zaprojektowany do transportu, podnoszenia i instalacji morskich turbin wiatrowych, części łączących i podstaw. W porównaniu z istniejącymi statkami do instalacji turbin wiatrowych typu jack-up, statek oferuje lepszą manewrowość; nie tylko będzie w stanie przewozić turbiny wiatrowe i podstawy nowej generacji, ale większa przestrzeń pokładowa zoptymalizuje prace instalacyjne na morzu oraz zmniejszy zużycie paliwa i emisje. Statek będzie nie tylko gotowy na przyszłość morskiej energii odnawialnej, ale będzie również dostępny do użytku w przemyśle naftowym i gazowym, a także do rozbiórki konstrukcji morskich.

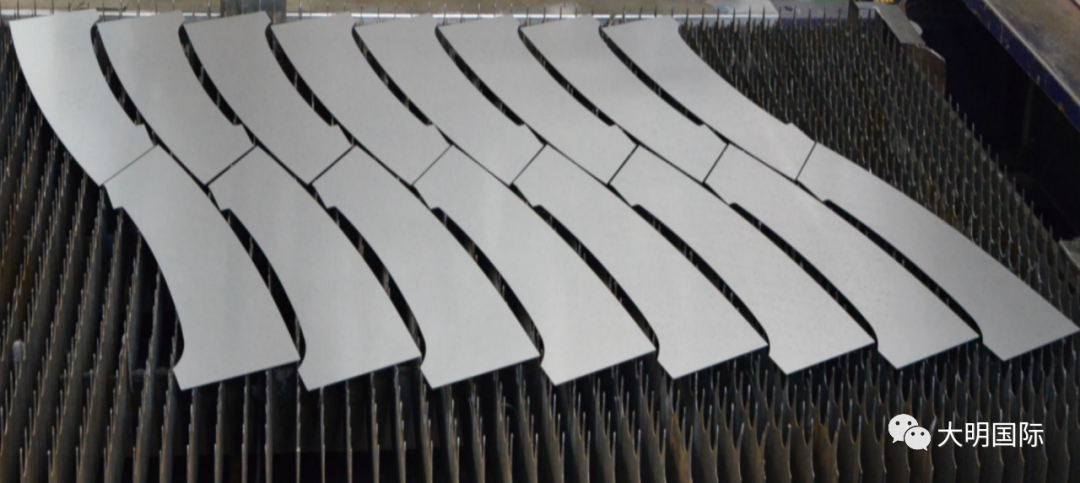

Statek składa się głównie z ponad 3000-tonowego żurawia do wbijania pali o głębokości roboczej ponad 80 metrów, ładowności około 14 000 ton i pojemności 110 osób. Statek jest wyposażony w cztery nogi palowe, aby utrzymać stabilne warunki pracy na morzu i jest wyposażony w system DP2. Produktem dostarczonym tym razem jest stała rama palowa (skrzynia biegów) dla czterech nóg palowych statku, łącznie 12 sztuk, przy wadze pojedynczego elementu sięgającej 90 ton. Daiming z powodzeniem ukończył przetwarzanie wspierające tego projektu, korzystając z możliwości kompleksowej obsługi w zakresie dostaw materiałów, cięcia, spawania, obróbki cieplnej, obróbki skrawaniem, natryskiwania i tak dalej.

Przegląd przypadków:

Pomyślna dostawa nowej morskiej wieży odsiarczania COSCO dla Daiming Heavy Industries.

Niedawno Daming Heavy Industry ukończył dwa zestawy wież odsiarczających ze stali nierdzewnej dla nowych statków pod COSCO z Nantong COSCO Group i z powodzeniem dostarczył je do Zhoushan Terminal Owner, a czwarty zestaw został zasadniczo ukończony pod koniec 28 listopada. W dniu 28 listopada właściciel, CLEAN MARINE i COSCO doceniły poziom i możliwości Daming w zakresie produkcji i wsparcia, a także zaprezentowały baner, aby okazać swoje uznanie i zachętę.

Podczas procesu produkcyjnego dział produkcyjny Daiming Heavy Industry opiera się na bogatym doświadczeniu we wspieraniu wieży płuczkowej, dziale technicznym, aby wykonać dobrą robotę w zakresie przepisów dotyczących procesu produkcyjnego i produkcji wraz z trudnościami produktu na wczesnym etapie produkcji jednego po drugim rozkładu. Wszystkie części projektu w centrum przetwarzania Jiangsu Daming i Daming Jingjiang do cięcia i przetwarzania, wysoka wydajność przepływu do następnego spawania, okrągły okrąg, gięcie i inne procesy, w pełni odzwierciedlające zalety współpracy grupowej. Ponieważ wszystkie produkty są specjalnym materiałem z cienkiej blachy ze stali nierdzewnej, należy wziąć pod uwagę łatwą deformację płyty ściennej i spawania płyty dolnej oraz inne czynniki, Daiming Heavy Industry zastosował automatyczne spawanie plazmowe, piękne formowanie spoin, dużą prędkość spawania, wysoką wydajność.

Ze względu na napięty harmonogram właściciela statku, w obliczu wysokich wymagań dotyczących jakości i dostawy, zespół projektowy dokonał rozsądnego wdrożenia dla całego postępu i pokonał trudności we wspólnych wysiłkach. Od wprowadzenia materiału do dostawy pierwszego produktu minęło zaledwie 45 dni, kończąc serię procesów od rozładunku, łączenia i spawania, gięcia, okrążania, montażu, wiercenia, wytrawiania i pasywacji. Pomyślna promocja tego projektu stanowi skok w możliwościach produkcyjnych Daming Heavy Industry i wyznacza nowy punkt odniesienia.

Ponadto Daming dopasował również wewnętrzną gródź największego na świecie 49 000-tonowego chemikaliowca Hudong-Zhonghua, który został przetworzony z dupleksowej stali nierdzewnej. Opierając się na regionalnej przewadze miejsca projektu i silnej przewadze Daming Heavy Industry w zakresie rozszerzonego przetwarzania, Daming Heavy Industry zapewnił klientom następujące usługi: "usuwanie rysunków - usuwanie materiału - ukosowanie - spawanie - gięcie - dystrybucja". Spawanie - gięcie - dystrybucja" - cały proces głębokiego przetwarzania usług wspierających "kamerdynera", ale także największy na świecie tonaż głównych elementów cysterny chemicznej ze stali nierdzewnej w ogólnej lokalizacji klasycznego przypadku.

Takie osiągnięcia wspierające są krok po kroku świadectwem reputacji usług Daming w przemyśle stoczniowym i offshore, a także wynikiem wysiłków Daming w głębokiej orce branży. Jakie są zróżnicowane przewagi konkurencyjne Daming w zakresie wspierania sprzętu związanego z przemysłem stoczniowym i offshore?