Hubei Daming, a leading name in high-strength steel processing, has once again proven its technical expertise and manufacturing prowess with the delivery of key structural components for a major domestic dump truck manufacturer. This achievement not only highlights Daming’s technical capabilities but also reinforces its ability to meet the tough demands of producing large, complex, and high-strength components crucial to the heavy truck industry.

Meeting the Demands of High-Strength Structural Components

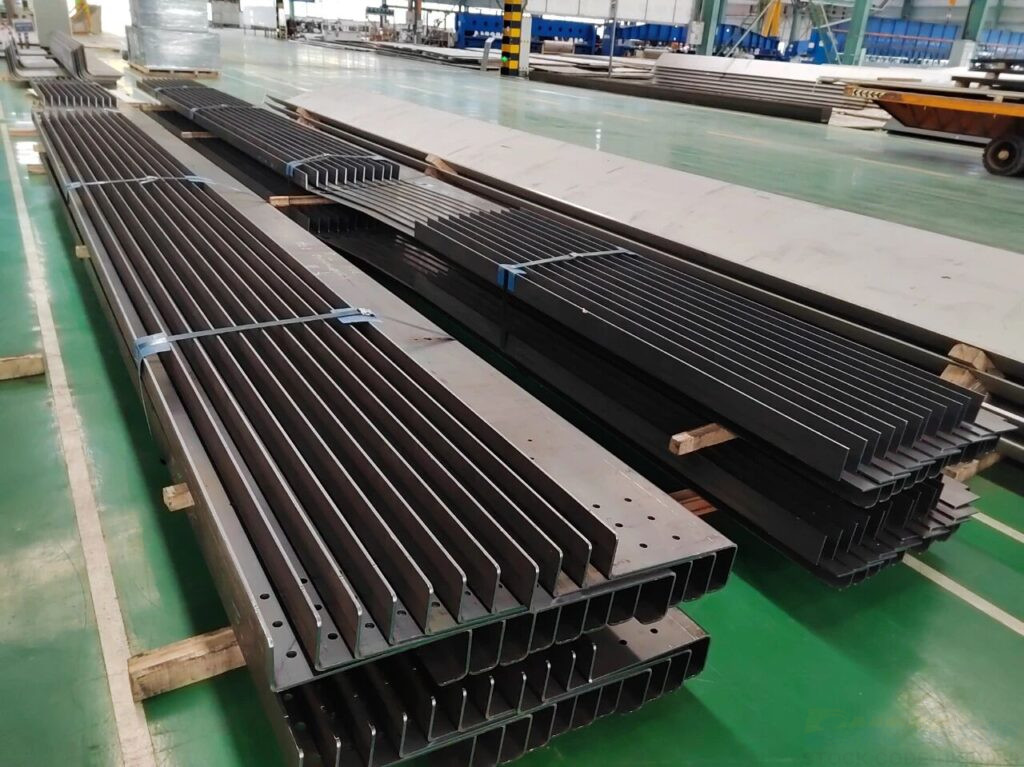

The latest project saw Daming manufacturing vital bending components from high-strength steel, known for its durability and ability to withstand extreme conditions. These parts, which had a plate thickness of 6mm and lengths of 10-11 meters, needed to meet the customer’s exacting standards for precision, cutting accuracy, bending control, and deformation management.

Given their size and irregular shape, these components were particularly challenging to produce. Daming’s team not only applied advanced technical knowledge but also demonstrated exceptional problem-solving skills and seamless collaboration across multiple departments. The customer required a perfect fit for their vehicle model, and Daming’s team rose to the occasion, leveraging their deep expertise in large-scale component manufacturing.

From Prototype to Full Production: A Seamless Journey

The customer initially requested two sets of samples to ensure the parts were compatible with their vehicle design. Daming’s integrated “business-process-production” collaboration system ensured a smooth and efficient trial production process. From cutting and blanking to precision bending and testing, the team worked closely together to deliver sample components that matched the vehicle specifications perfectly, earning the customer’s trust.

Impressed with the performance of the samples, the customer quickly placed an order for over 40 sets of components, with a very tight deadline of just three days for delivery. Under pressure from both the timeline and volume, Daming’s production, sales, and technical teams worked tirelessly to meet the demand. They optimized scheduling, mold systems, and bending parameters to solve challenges such as mold interference and deformation control. In the end, all components were delivered on time, meeting the highest quality standards and ensuring customer satisfaction.

Excellence in Rapid Manufacturing and Quality Control

This project is a prime example of Daming’s ability to manage complex manufacturing tasks with both speed and precision. The company’s success lies in its holistic approach to technical collaboration and its unwavering commitment to quality control throughout the entire process. From initial consultations and design to final delivery, Daming proved its rapid-response capabilities and manufacturing excellence, setting the stage for future high-strength steel processing projects.

In the heavy truck industry, where performance demands are high, Daming’s ability to deliver large, high-strength components quickly and accurately positions the company as a trusted partner for OEMs (Original Equipment Manufacturers) in need of reliable, high-quality steel parts. Their ability to fulfill demanding projects on tight deadlines—without compromising on quality—is a testament to Daming’s leadership in the steel processing sector.

Pioneering High-Strength Steel Services for Heavy Machinery

Since launching its carbon steel processing service platform in 2012, Daming has rapidly become a leader in high-strength steel processing. Over the years, the company has expanded its capabilities to offer cutting-edge solutions for industries ranging from construction machinery to aerospace and automotive.

Daming’s high-strength steel processing services cover a broad range of products, from ultra-thin 0.8mm materials to ultra-high-strength steels exceeding 1400MPa. Some of the company’s notable achievements include:

-

Leveling ultra-high-strength BS960E hot-rolled coils, allowing Daming to replace imported materials with domestically produced alternatives.

-

Processing near-1400MPa tensile strength automotive martensitic ultra-thin steel, such as the HC1030/1300MS used in the automotive industry.

-

Bending services for ultra-thick, ultra-high-strength steel booms used in Zoomlion’s heavy equipment.

-

Cutting services for high-strength steel parts used in aerial work platforms, supporting leading global manufacturers.

Additionally, Daming provides specialized services like leveling high-strength magnetic yoke steel and custom processing for wear-resistant steels, achieving yield rates exceeding 90% in some cases. This broad range of capabilities positions Daming as an industry leader, capable of addressing diverse customer needs across various sectors.

Building Strategic Partnerships Across the Industry

Daming’s technical expertise has made it a trusted partner for many top names in the global manufacturing and construction industries. The company is a strategic supplier for XCMG Group, the largest blanking parts supplier for Lingong Heavy Machinery, and a key service provider for Henan Juntong. Daming’s commitment to excellence has earned it numerous awards, including Zoomlion Mining Machinery’s “Best Quality Award”, JLG’s “Outstanding Performance Leader in Stable Supply Chain Delivery”, and Changzhou LiuGong’s “Excellent Delivery Award”.

Daming’s dedication to quality, efficiency, and customer satisfaction is evident in its strong partnerships with both domestic and international giants such as Manitowoc, Komatsu, and LiuGong. These collaborations solidify Daming’s position as a key player in both the heavy machinery and high-strength steel industries, driving innovation and delivering reliable solutions to industry leaders worldwide.

Looking Ahead: Advancing Steel Manufacturing Capabilities

As Daming continues to refine its operations and expand its technical expertise, the company remains committed to delivering high-end manufacturing solutions for the heavy truck and machinery industries. With a focus on process technology, equipment capabilities, and rapid-response manufacturing, Daming is well-positioned to meet the growing demands of the global market.

Looking to the future, Daming plans to further strengthen its role as a leading provider of high-strength steel components, continually improving its offerings to deliver more efficient, reliable, and cost-effective solutions for its customers. By maintaining a focus on innovation and its unwavering commitment to excellence, Daming is set to continue shaping the future of high-strength steel processing and setting the industry standard.