Damingilla on kokemusta merenkulkulaitteiden käsittelystä ja tukemisesta, ja se luottaa rikkaaseen tuotanto- ja palvelutiimiin sekä myyntiin, tekniikkaan, tuotantoon, laatuun ja muihin monen osapuolen yhteistyön tiimeihin. Tällä hetkellä Daming on tarjonnut korkealaatuisia paketteja meriteollisuuden asiakkaille, kuten kemikaalisäiliöalusten sisäisiä laipioita, suurimman merituulivoimalaitoksen asennusaluksen kiinteää paalurunkoa (vaihdelaatikko), meripesuritorneja, meripolttoainesäiliöitä ja niin edelleen.

Tapauskatsaus:

Yara Marine Technology (YMT) -alusten pesuritorni

15. tammikuuta 2019 Daming Heavy Industries (DHI) toimitti onnistuneesti ensimmäisen YMT:tä tukevan offshore-meripesuritornien sarjan, ja tämä toimitus on DHI:lle tärkeä virstanpylväs meripesuritornituotteiden käsittelypalvelussa.

YMT on maailmanlaajuisesti toimiva, integroitu rikinpoisto- ja denitrifikaatiopalvelujen (FGD) tarjoaja, joka on toiminut luotettavasti yli miljoona tuntia yli sadalle varustamolle ympäri maailmaa. Laivojen rikinpoistopesureiden alalla YMT:llä on aina ollut hallitseva etu ja teknologinen johtoasema markkinoilla.

Merenkulun tärkeimpänä ympäristönsuojeluvälineenä merenkulun rikinpoistopesurin torni on valmistettu nikkelipohjaisesta korkealaatuisesta seoksesta, jonka valmistus on vaikeaa ja riskialtista. Daming Heavy Industry voitti monia teknisiä vaikeuksia tuotantoprosessin aikana, kuten hitsauksen muodonmuutokset, ohutseinäiset sylinteriliitokset ovat helposti muodonmuutoksia jne. Kaikkien projektin jäsenten yhteisten ponnistelujen ja yötä päivää kestäneen taistelun ansiosta ensimmäinen pesuritorni-sarja toimitettiin kuukautta ennen aikataulua.

Asiakkaan ja laivanvarustamon edustajat arvostivat suuresti Daiming Heavy Industryn tehokkuutta ja ammattitaitoa ja ilmaisivat vahvan tahtonsa pitkäaikaiseen yhteistyöhön. Tällä hetkellä Daming Heavy Industryn työpajassa valmistetaan järjestelmällisesti seuraavia suursarjatuotteita.

Tapauskatsaus:

Maailman suurimman ja Kiinan ensimmäisen merituulivoimalaitoksen asennusaluksen N966 kiinteän paalurunkoprojektin onnistunut luovutus

Daming toimitti Qidong COSCO Shipping Offshore Engineering Co., Ltd:lle onnistuneesti maailman suurimman merituulivoimalaitoksen kiinteän paalurungon (vaihdelaatikko), mikä merkitsi Damingin menestyksekästä tuloa merituulivoimalaitosten asennusaluksissa käytettävien suurten mekaanisten rakenneosien valmistuksen alalle.

Qidong COSCOn rakentama eurooppalaisen varustamon N966 Jack-up-tuulivoima-asennusalushanke on suunniteltu erityisesti merituulivoimaloiden, liitososien ja alustojen kuljetukseen, nostamiseen ja asentamiseen. Nykyisiin tuulivoimaloiden asennusaluksiin verrattuna alus on paremmin ohjattavissa; alus pystyy kuljettamaan seuraavan sukupolven tuulivoimaloita ja tukikohtia, ja suurempi kansitila optimoi offshore-asennustyöt ja vähentää polttoaineen kulutusta ja päästöjä. Alus ei ole valmis ainoastaan uusiutuvan merienergian tulevaisuutta varten, vaan sitä voidaan käyttää myös öljy- ja kaasuteollisuudessa sekä offshore-rakenteiden purkamiseen.

Alus koostuu pääasiassa yli 3 000 tonnin paalunosturista, jonka käyttösyvyys on yli 80 metriä, hyötykuorma noin 14 000 tonnia ja kapasiteetti 110 henkilöä. Alus on varustettu neljällä paalujalalla vakaiden työskentelyolosuhteiden ylläpitämiseksi merellä, ja se on varustettu DP2-järjestelmällä. Tällä kertaa toimitettu tuote on aluksen neljän paalujalan kiinteä paalurunko (vaihdelaatikko), joita on yhteensä 12 kappaletta, ja yhden kappaleen paino on 90 tonnia. Daiming saattoi onnistuneesti päätökseen tämän hankkeen tukikäsittelyn hyödyntämällä yhden luukun palvelukykyä materiaalitoimituksista, leikkauksesta, hitsauksesta, lämpökäsittelystä, koneistuksesta, ruiskutuksesta ja niin edelleen.

Tapauskatsaus:

COSCO:n uuden merenkulun rikinpoistotornin onnistunut toimitus Daiming Heavy Industriesille.

Hiljattain Daming Heavy Industry on saanut valmiiksi kaksi sarjaa ruostumattomasta teräksestä valmistettuja rikinpoistotorneja uusiin aluksiin Nantong COSCO Groupin COSCOn alaisuudessa ja toimittanut ne onnistuneesti Zhoushanin terminaalin omistajalle, ja neljäs sarja valmistui periaatteessa 28. marraskuuta lopussa. Marraskuun 28. päivänä omistaja, CLEAN MARINE ja COSCO tunnustivat Damingin valmistuksen ja tuen tason ja kyvyn ja esittivät banderollin osoittaakseen arvostustaan ja kannustustaan. kannustusta.

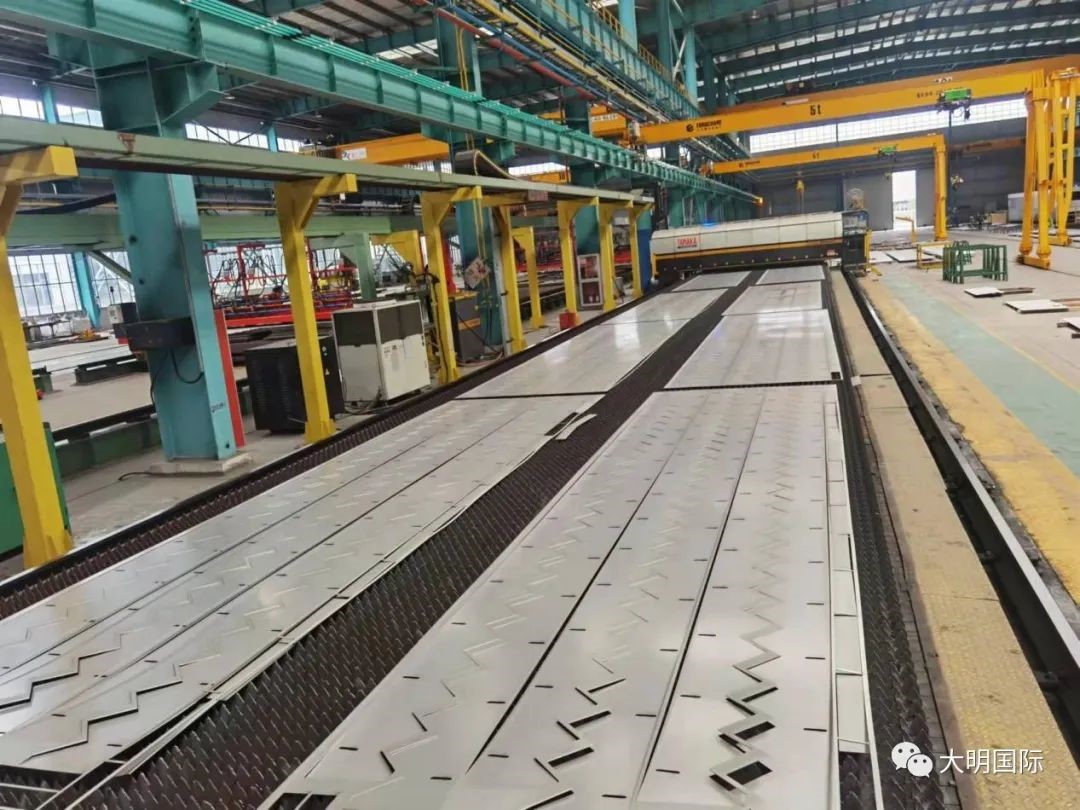

Tuotantoprosessin aikana Daiming Heavy Industryn tuotanto-osasto tukeutuu pesuritorni-tuen rikkaaseen kokemukseen, teknisen osaston tekemään hyvää työtä valmistusprosessin säännöksistä ja tuotannosta yhdessä tuotteen vaikeuden kanssa tuotannon alkuvaiheessa yksi kerrallaan hajoamisen kanssa. Kaikki osat projektin Jiangsu Daming ja Daming Jingjiang käsittelykeskus leikkaus ja käsittely, korkea tehokkuus virtaus seuraavaan hitsaus, ympyrä pyöreä, taivutus ja muut prosessit, täysin heijastavat etuja ryhmäyhteistyön. Koska tuotteet ovat kaikki ohutlevyisiä ruostumattomasta teräksestä valmistettuja erikoismateriaaleja, on otettava huomioon seinälevyn ja pohjalevyn hitsauksen helppo muodonmuutos ja muut tekijät, Daiming Heavy Industry käytti plasma-automaattihitsausta, hitsauksen muotoilua kauniisti, nopeaa hitsausnopeutta, korkeaa tehokkuutta.

Omistajan tiukan aikataulun vuoksi ja korkeiden laatu- ja toimitusvaatimusten vuoksi projektiryhmä otti kohtuullisen käyttöön koko edistymisen ajan ja voitti vaikeudet yhteisin ponnistuksin. Materiaalin saapumisesta ensimmäisen tuotteen toimittamiseen kului vain 45 päivää, ja prosessit saatiin päätökseen purkamisesta, liittämisestä ja hitsaamisesta, taivuttamisesta, kiertämisestä, kokoamisesta, poraamisesta, peittämisestä ja passivoinnista. Tämän hankkeen menestyksekäs edistäminen merkitsee harppausta Daming Heavy Industryn valmistuksen tukikapasiteetissa ja asettaa uuden vertailuarvon.

Lisäksi Daming sovitti myös Hudong-Zhonghuan maailman suurimman, 49 000 tonnin kemikaalisäiliöaluksen sisäisen laipion, joka käsiteltiin ruostumattomasta duplex-teräksestä. Daming Heavy Industry tarjosi asiakkaille seuraavat palvelut tukeutuen hankepaikan alueelliseen etuun ja Daming Heavy Industryn vahvaan laajennettuun jalostusetuun: "Piirroksen poisto - materiaalin poisto - viistäminen - hitsaus - taivutus - jakelu". -Hitsaus - Taivutus - Jakelu" koko prosessi "butler" syvä käsittely tukipalvelut, mutta myös maailman suurin tonnimäärä ruostumattomasta teräksestä valmistetun kemikaalisäiliöauton ydinkomponentit yleisen lokalisoinnin klassisen tapauksen.

Tällaiset tukisaavutukset ovat vaiheittainen todiste Damingin palvelumaineesta laivanrakennus- ja offshore-teollisuudessa, ja se on myös tulos Damingin ponnisteluista alan syvällisessä kyntämisessä. Mitkä ovat Damingin kilpailuedut laivojen offshore-teollisuuteen liittyvien laitteiden tukemisessa?