As global equipment manufacturing continues to evolve toward larger structures, higher strength materials, and tighter tolerances, precision sheet metal processing has become a critical foundation for product reliability and performance. At Hubei Daming, one of Daming’s eleven processing centers, the broad industry experience, advanced forming capabilities, and systematic process control in Precision Sheet Metal Processing enable us to support demanding export equipment projects with confidence and consistency.

Meeting the Challenges of Large-Scale Sheet Metal Forming

Large-format carbon steel components present unique manufacturing challenges. Issues such as welding deformation, stress concentration during forming, and dimensional instability in ultra-wide plates can directly impact assembly accuracy and long-term structural performance. For curved and irregular components in particular, maintaining consistent geometry across batch production requires both robust equipment capacity and precise process management.

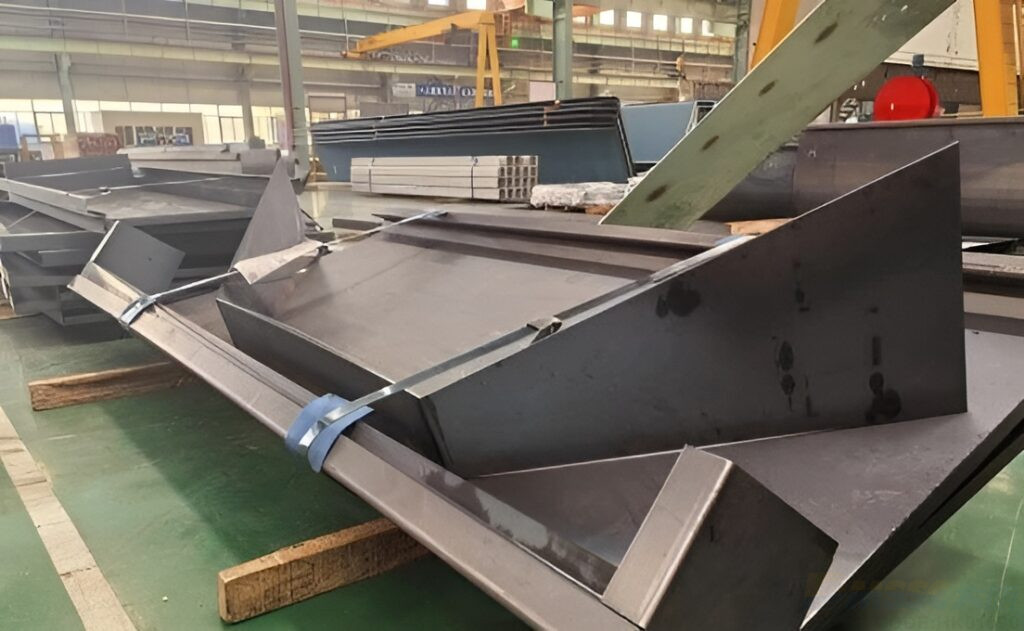

Recently, Hubei Daming undertook a complex curved component project for large-scale export equipment. Leveraging a comprehensive lineup of CNC bending machines ranging from 50T to 2000T, the carbon steel processing team combined digital process data with hands-on production experience to develop a stable, repeatable manufacturing solution.

Key technical challenges addressed during the project included:

-

Control of welding deformation to maintain structural integrity

-

Safe and stable lifting of irregularly shaped components

-

Precision straightening of thin plates without surface damage

-

Prevention of sagging and loss of accuracy in ultra-wide plate forming

Through detailed process planning and continuous on-site adjustment, each steel plate was formed to closely match the required design curvature, ensuring compatibility with downstream assembly.

Process Integration and Precision Under Tight Timelines

With both delivery deadlines and quality standards clearly defined, Daming’s production team focused on improving efficiency without compromising accuracy. By integrating forming and correction processes, optimizing bending parameters, and developing customized tooling, the team successfully compressed production cycles while maintaining stable quality output.

The final results demonstrated the effectiveness of this approach:

-

Over 500 curved components delivered on schedule

-

Dimensional tolerances controlled within ±1mm

-

100% pass rate during customer on-site acceptance

These results highlight Daming’s ability to handle batch production of complex components while maintaining consistent accuracy across large volumes.

A Systematic Approach to Quality and Project Execution

Beyond individual manufacturing steps, Daming emphasizes end-to-end project management. From early-stage technical review and process simulation to in-process quality inspection, final verification, and export logistics coordination, each department works closely to ensure smooth execution and risk control.

This cross-functional collaboration allows Daming to respond quickly to design changes, production challenges, and delivery adjustments—an increasingly important capability in today’s fast-paced equipment manufacturing environment.

Building Long-Term Value for Equipment Manufacturers

As industries such as energy, infrastructure, heavy machinery, and industrial automation continue to demand larger, more complex metal structures, precision sheet metal suppliers must offer more than basic fabrication. They must provide engineering support, stable quality systems, and the ability to scale production without sacrificing accuracy.

Hubei Daming’s competitive strength lies not only in its advanced equipment and processing capacity, but also in its commitment to understanding customer applications and translating technical requirements into reliable, manufacturable solutions.

Delivering Confidence Through Precision

At Hubei Daming Precision Sheet Metal Processing, every project is approached with the same goal: to deliver components that perform reliably in real-world applications.

We don’t just supply sheet metal parts—we support our customers’ products, timelines, and reputations.

Contact Hubei Daming Precision Sheet Metal Processing to learn how our precision engineering capabilities can support your next large-scale manufacturing project.