On January 13, delegations from CB&I and SNP visited Daming Jingjiang for a site tour and business exchange.

The visiting team included Mr. Ajay Mathew, Mr. Gufran Maruf, and Mr. Rollin Ding from CB&I, as well as Mr. Larry Zhao and Ms. Alice Kim from SNP. The delegation was warmly received by Mr. Deng Liangfeng, General Manager of Jiangjiang Daming, one of Daming Group’s 11 processing centers; Mr. Zhou Yingyu, Assistant General Manager of Jiangsu Daming Engineering Technology Service Company; and Mr. Chen Hequn, Assistant General Manager of Jingjiang Daming.

Strengthening Collaboration Across the Global Storage Tank and Steel Industries

The global storage tank industry is experiencing sustained growth, driven by rising demand for energy storage, LNG infrastructure, petrochemical expansion, and the ongoing transition toward cleaner and more efficient energy systems. Large-scale storage tanks—particularly cryogenic and low-temperature tanks—place increasingly stringent requirements on material quality, processing precision, delivery reliability, and project coordination. High-performance steels such as 9Ni steel play a critical role in ensuring safety, durability, and long-term operational stability in these applications.

At the same time, the steel industry is undergoing structural transformation, with customers seeking integrated solutions that combine material supply, advanced processing, prefabrication, quality assurance, and logistics. Against this backdrop, close collaboration among engineering companies, steel service providers, and fabrication specialists has become essential to improving project efficiency, reducing overall costs, and ensuring on-time delivery for complex international projects.

Comprehensive Capabilities Supporting Storage Tank Projects

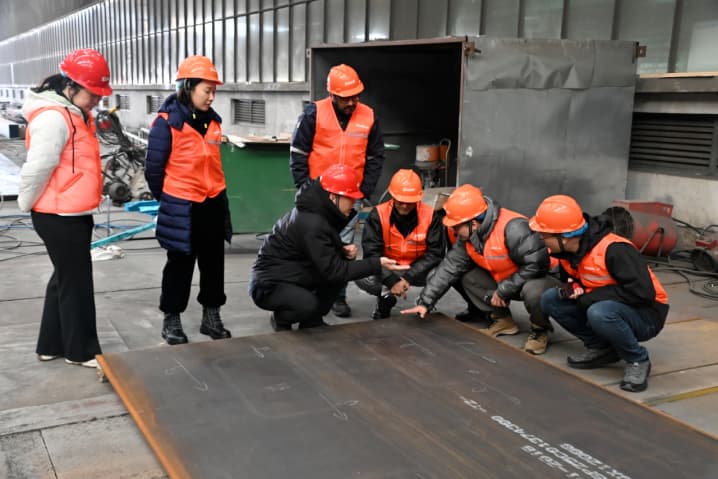

During the visit, the CB&I and SNP representatives toured Daming’s Jingjiang manufacturing base and Yangtze River dock, gaining a comprehensive understanding of Daming’s operational capabilities and its integrated one-stop service model. This model covers the entire value chain—from material sourcing and steel processing to prefabrication, inspection, packaging, and logistics—enabling Daming to support storage tank projects from early-stage preparation through final delivery.

With extensive experience in serving major global energy and infrastructure projects, Daming has developed strong capabilities in the processing and prefabrication of high-grade steels, including 9Ni steel for inner tank applications. By providing precision cutting, forming, welding, and surface treatment under controlled conditions, Daming helps customers enhance construction efficiency, reduce on-site workload, and improve overall project quality.

Advanced Quality Management and Supply Chain Integration

At the subsequent business meeting, Mr. Zhou Yingyu expressed his appreciation for the visit and shared Daming’s accumulated experience in prefabrication for large storage tank projects, emphasizing the company’s deep technical expertise and continuous investment in advanced equipment and skilled personnel.

Mr. Deng Liangfeng further elaborated on Daming’s comprehensive quality management system. Dedicated quality control teams monitor and record production data in real time across every stage of the process, including raw material preparation, cutting, forming, welding, anti-corrosion treatment, final inspection, and packaging. This closed-loop quality management approach ensures stable product performance, strict compliance with international standards, and full traceability throughout the production lifecycle—key requirements for storage tank and energy infrastructure projects.

In addition, Daming’s strategic location along the Yangtze River provides significant logistics advantages. Efficient river transportation, combined with coordinated land and sea logistics solutions, allows for the safe and timely delivery of oversized and heavy steel components, further supporting global tank projects with demanding schedules.

Industry Recognition and Future-Oriented Cooperation

The CB&I and SNP representatives spoke highly of Daming’s service model, on-site management, mature production processes, and efficient logistics system. They noted that Daming’s integrated capabilities align well with the evolving needs of the global storage tank and steel industries, particularly in projects requiring high-quality materials, strict quality control, and reliable delivery performance.

Both sides engaged in in-depth discussions on ongoing projects, delivery planning, logistics coordination, and potential areas for expanded cooperation. Looking ahead, all parties expressed a strong commitment to establishing long-term, mutually beneficial partnerships. Discussions focused on building a collaborative model centered on industrial chain integration, joint technology development, capacity sharing, and coordinated market expansion.

By leveraging their respective strengths—CB&I’s global engineering leadership, SNP’s steel trade expertise, and Daming’s advanced processing, prefabrication, and logistics capabilities—the three companies aim to deepen cooperation across the storage tank and steel industries, jointly enhance project execution efficiency, and create greater value for customers worldwide.

About CB&I

CB&I is the world’s leading designer and builder of storage facilities, tanks, and terminals. With more than 60,000 structures completed over its 135+ year history, CB&I delivers world-class storage solutions for some of the most complex energy infrastructure projects worldwide. CB&I is owned by a consortium of financial investors led by Mason Capital Management LLC.

About SNP LIMITED

SNP LIMITED is a global steel service company and a leading player in Korea’s steel trade industry. Since its establishment in January 2008, SNP has pursued future-oriented and innovative development through the dedication and expertise of its professional team, supported by extensive experience across the steel industry.