Jingjiang Daming has recently completed the prefabrication of a critical component for a large export storage tank — marking another milestone in the company’s pursuit of innovation and precision manufacturing. This project not only represented a major order, but also a rigorous test of Daming’s technical strength and engineering craftsmanship.

The project’s greatest challenge centered on forming the massive spherical head of the tank — a complex melon-shaped top cover requiring exceptional accuracy and surface quality. Meeting these high standards pushed the limits of traditional fabrication methods and called for a new approach.

01. Early Challenges: From Setback to Insight

At the start, Daming’s team adopted the conventional “contour tooling + rib welding” process. However, as fabrication progressed, problems emerged. While areas supported by dense ribs held their shape, sections near the tail of the fan-shaped structure suffered from stress release. The stored elastic energy in the steel plate caused rebound and distortion, destroying the smooth curvature required for the spherical head.

Recognizing that traditional methods were working against the material’s internal stress, Daming’s engineers shifted perspective. Instead of resisting the steel’s natural behavior, they sought to guide it — allowing the plate to form more uniformly and predictably.

02. Process Innovation: Guiding the Steel to Take Shape

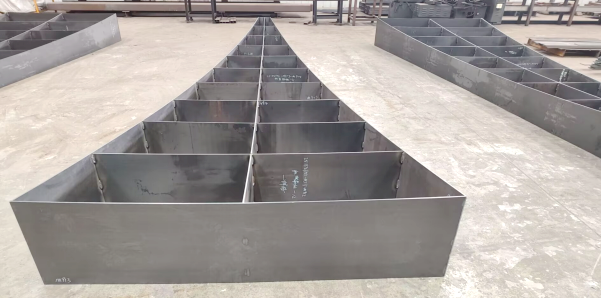

After careful analysis and testing, Daming’s technical team developed an innovative “multi-blade bending pre-forming” process. By introducing multiple controlled bends during forming, the internal stress within the steel plate is gradually released and evenly distributed.

This change turned the forming process from “passive correction” — forcing the steel into shape — into “active guidance,” allowing the material to flow naturally into its designed curvature. The very first prototype produced with this method achieved a perfect fit with the tooling, marking a fundamental breakthrough in forming large spherical heads.

03. Proven Results: Efficiency, Quality, and Recognition

The new process delivered outstanding results. The first sample passed inspection on the initial attempt and received high praise from project supervisors. The improved technique not only solved the springback issue but also boosted forming efficiency and improved product consistency.

Since implementation, the batch qualification rate of tank heads produced using this method has reached 100%, reflecting the stability and reliability of the new process. These gains also translate into shorter production cycles, smoother assembly, and higher overall quality — key advantages in the competitive global storage tank market.

Driving Progress Through Innovation

Daming’s success in overcoming this manufacturing challenge showcases the company’s deep expertise in large-scale steel fabrication and its commitment to continuous process improvement. By tackling complex forming problems and developing practical, efficient solutions, Daming continues to raise the bar for quality and innovation in the storage tank industry.

This achievement not only ensures the smooth delivery of the current export project but also strengthens Daming’s technical foundation for future international collaborations — reinforcing its position as a trusted partner in high-end steel structure and pressure vessel manufacturing.

Jingjiang Daming — Shaping Steel, Driving Innovation, Delivering Excellence.