Innovative forming techniques, cross-team collaboration,

and high-precision manufacturing redefine what’s possible

in oversized gutter fabrication.

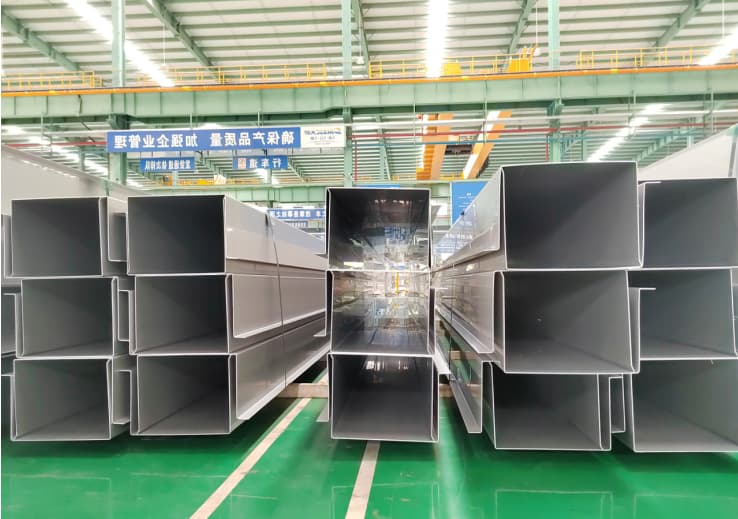

In a powerful demonstration of advanced manufacturing capability and process innovation, Hubei Daming, one of the eleven regional processing centers under Daming International, has completed a technically demanding order for ultra-long, precision-bent stainless steel gutters. Each component, measuring an impressive 9 meters in length and 3mm in thickness, was delivered with flawless results—meeting the customer’s strictest standards and securing immediate follow-up orders.

This accomplishment underscores not only Hubei Daming’s manufacturing excellence but also the broader strength of Daming International’s national processing network, which is positioned as a leader in high-end stainless steel and carbon steel fabrication, supply chain integration, and customized metal solutions.

Why Stainless Steel Gutters?

Stainless steel gutters play a vital role in modern steel structure systems, particularly in large-scale industrial and commercial applications such as logistics centers, factories, airports, and infrastructure projects. Their high corrosion resistance, structural durability, and low maintenance requirements make them a preferred choice for long-term performance, especially in harsh or chemically exposed environments.

However, to achieve these advantages in real-world applications, gutter systems must be fabricated with extreme dimensional precision, uniformity, and smooth surface finishes. Any defects—such as warping, misalignment, or residual stress—can compromise water flow, create installation challenges, or shorten service life.

This is where advanced steel processing capabilities become crucial. Long, thin stainless steel sheets are especially prone to deformation during forming. Achieving consistent angles and curvature along a 9-meter span requires exceptional control over bending force distribution, tool alignment, and stress management. Only a small number of manufacturers in China possess the integrated capabilities—both in equipment and expertise—to produce such components at scale and with reliable repeatability.

Overcoming the Limits of Conventional Equipment

Despite the availability of 1,000-ton twin press brakes at Hubei Daming, the equipment’s effective length (8.2 meters) was insufficient for the 9-meter gutter requirement. Rather than outsourcing or segmenting the panels—solutions that would compromise both cost and quality—the engineering team took an innovative approach.

They developed a custom mold spacing process, which cleverly redistributed forming forces to extend effective bending length beyond physical machine limits. By strategically placing dies and controlling stroke sequences, they achieved accurate, smooth bending across the entire length without deformation or unevenness.

This solution not only allowed for the single-piece forming of oversized panels but also preserved surface integrity and geometric consistency, exceeding the client’s expectations.

Teamwork and Process Integration Across Departments

The success of this project was also due to the seamless collaboration between Hubei Daming’s key departments—business, technology, and production—each playing a pivotal role in the end-to-end execution.

- The business team translated complex customer needs into a clear technical brief and ensured continuous alignment throughout the project cycle.

- The technical team designed and validated the specialized bending process, incorporating stress analysis and precision tooling strategies.

- The production team, leveraging years of hands-on experience with long, irregular parts, executed the operation with high skill and consistency—ensuring defect-free results.

- The production team, leveraging years of hands-on experience with long, irregular parts, executed the operation with high skill and consistency—ensuring defect-free results.

Such cross-functional coordination reflects the process integration philosophy of Daming International, where customer requirements are addressed through a combination of innovation, quality control, and engineering precision.

Customer Trust Earned, Second Batch Underway

The client—a steel structure company with extremely high quality standards—not only accepted the first batch with satisfaction but also placed a second round of orders shortly after delivery. This growing relationship is a direct reflection of the confidence Hubei Daming has earned through its performance and a testament to the long-term value created through technical capability and execution excellence.

Hubei Daming: A Strategic Hub Within Daming International

As one of Daming International’s eleven processing centers, Hubei Daming plays a strategic role in serving Central China’s industrial base. With access to shared group resources—including advanced equipment platforms, digital production systems, and centralized R&D expertise—Hubei Daming delivers localized responsiveness backed by national-level manufacturing strength.

Daming International, a leader in China’s metal processing industry, specializes in high-end stainless steel and carbon steel distribution, fabrication, and supply chain services. The group operates a network of processing centers across the country, enabling scalable solutions for construction, shipbuilding, energy, heavy machinery, and infrastructure sectors.

Looking Ahead

This recent success marks another milestone for Hubei Daming as it continues to push boundaries in high-precision, large-format metal fabrication. As the second batch of ultra-long gutters enters production and customer collaboration deepens, the future looks bright for both the client partnership and Hubei Daming’s continued contribution to innovation within the Daming International group.

About Hubei Daming

Hubei Daming is a regional processing center under Daming International, specializing in high-precision metal fabrication, sheet processing, and customized stainless steel solutions. Serving clients across Central China, the facility combines advanced equipment, skilled talent, and a culture of innovation to deliver top-tier results in challenging and high-demand applications.

About Daming International

Daming International Holdings is one of China’s leading enterprises in the metal processing industry. With eleven regional processing centers nationwide, the company offers comprehensive services—from raw material distribution to high-precision metal forming and customized fabrication—supporting key industries, including infrastructure, energy, shipbuilding, and industrial equipment.