Service cases:

Strength highlights! daming high performance daming Passenger Vehicles influence on automotive high-strength steel processing is steadily increasing(2023)

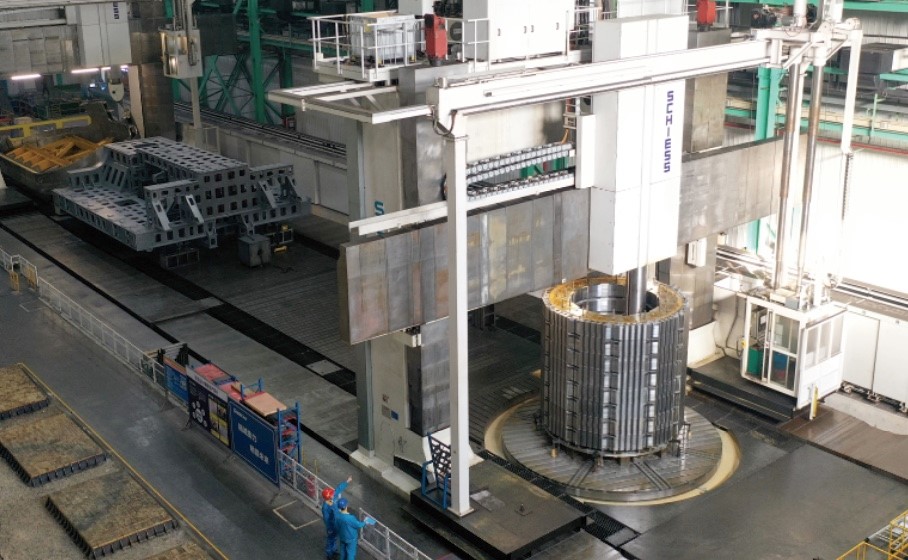

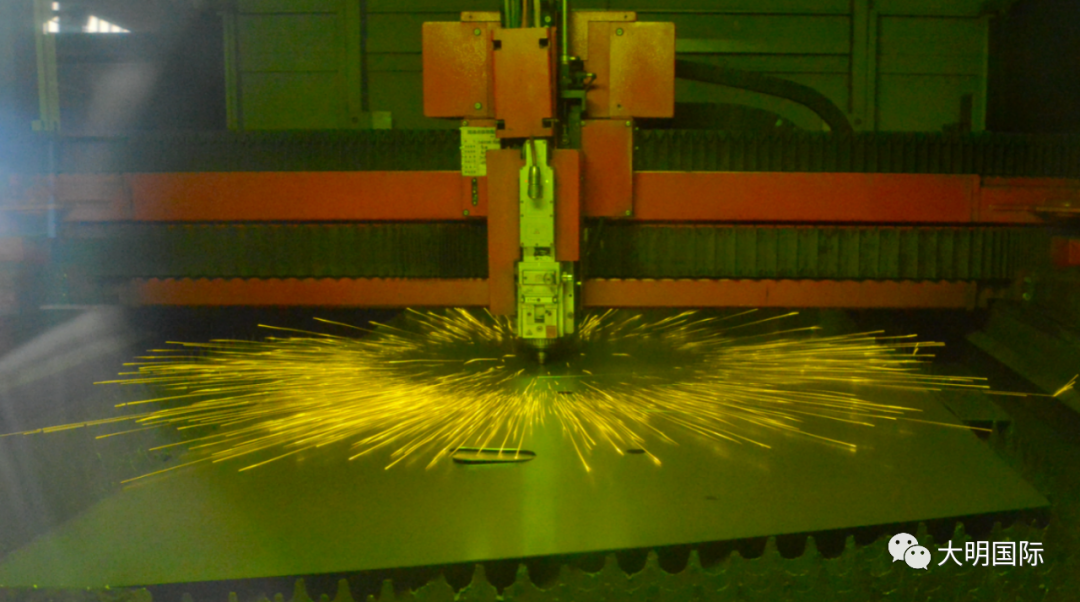

Recently, Daming Wuxi Processing Center successfully completed the processing of a batch of 1.6mm thick automotive martensitic high strength steel HC1030/1300MS, which won full recognition from the customer.

The actual yield strength of this steel (Gipa steel X-GPa) from fast delivery daming Passenger Vehicles is 1,200MPa, and the tensile strength is close to 1,400MPa, which can be used for automotive reinforcement parts, collision prevention parts, safety parts and exterior trim reinforcement parts, inner side door crash bars and door sill plates, etc.

How to do both “lightweight”, but also to ensure that the beams and other body components of the strong bearing capacity and long service life? This puts forward high requirements for the processing of automotive steel such as beam steel.

At present, relying on the “high-quality material supply (joint steel mills) + customized processing (combined with process requirements) + JIT logistics” full-process service model, Daming high-strength steel, wear-resistant steel processing “hard core” strength is becoming more and more prominent, not only for the customer to solve the problem of material ordering It has not only solved the pain points such as long material ordering cycle, insufficient internal stress release, low material yield and subsequent cracking for customers, but also further enhanced Daming’s influence in the field of automotive steel and other fields.

Advantages in automotive parts processing

– The market share of steel for automotive exhaust systems is as high as 25%.

– Has broken through the processing of automotive martensitic high-strength steel HC1030/1300MS

– Supporting support such as rolled profiles and stamped parts will be added to enhance the equipment security power

700,000 pieces have been shipped, Jiangsu Daming supporting international high-end new energy vehicle project (2020)

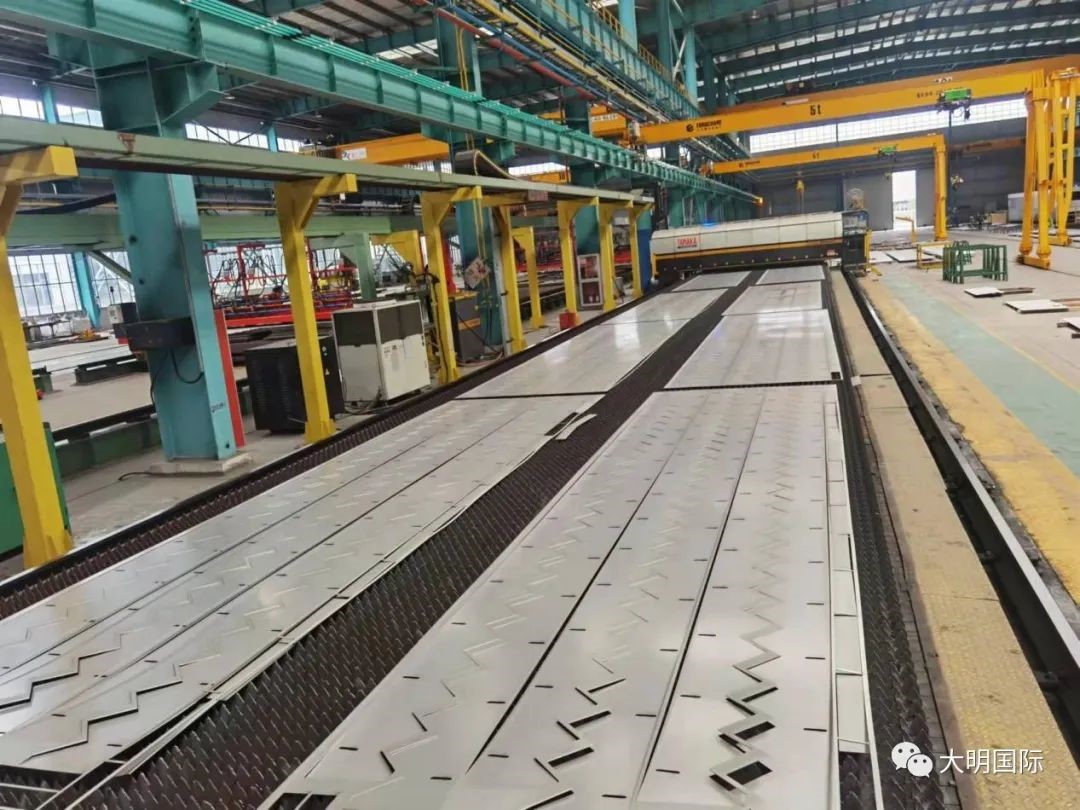

In the first half of 2020, Jiangsu Daming has processed 700,000 pieces of parts for a high-end electric vehicle project, with 4,000 pieces of incoming and shipping demand per week, the workshop is currently working overtime and continuously optimizing the cutting process and packaging.

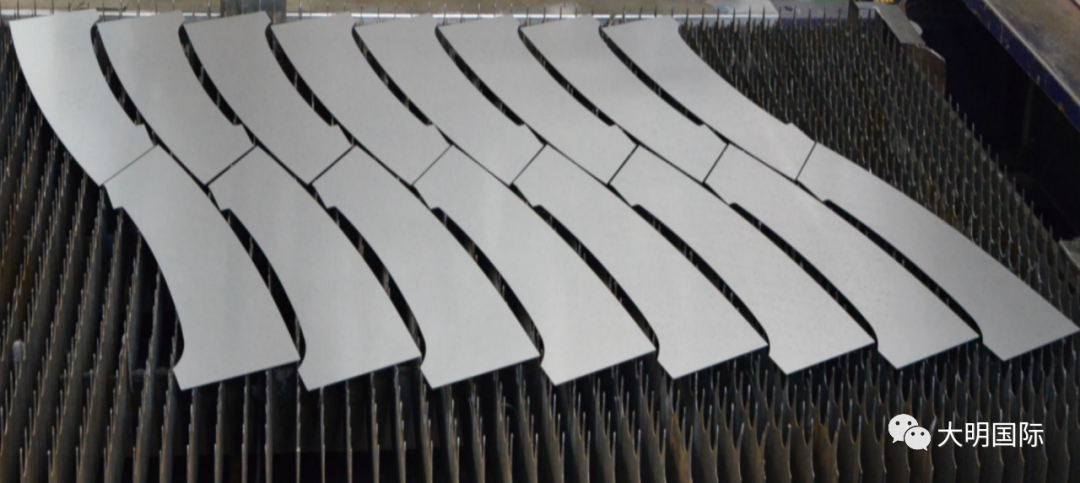

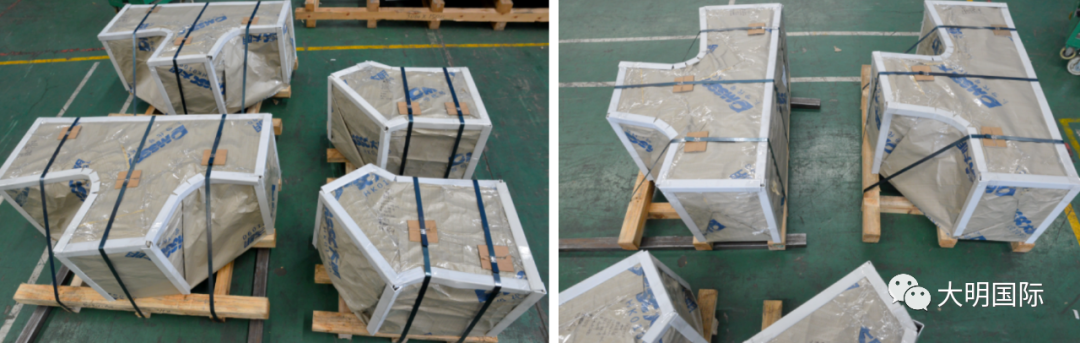

This batch of products is for high-end new energy vehicles supporting the body frame structural parts, by Jiangsu Daming to provide professional and efficient cutting and processing services, the products include 9 specifications, the total amount of millions of pieces. The products are made of special steel for automobiles, with a thickness of 1.2-2mm, and after being cut and processed by Jiangsu Daming through the fiber optic cutting process, the customer is in the process of stamping and other treatments. Through extensive market research and screening in the early stage, coupled with strict inspection, the customer was satisfied with Jiangsu Daming’s business responsiveness, processing quality, production management level and its supporting service capabilities, and thus reached a cooperation. During the pre-processing, Jiangsu Daming production and technical personnel solved some problems of plate shape, flatness, etc., and improved the processing quality and processing efficiency.

Launch of Jiangsu Daming’s high-end new energy automobile parts project (2020)

On January 10th, Jiangsu Daming held the launching ceremony of “High-end New Energy Vehicle Parts and Components Project”, which was attended by Zhang Feng, General Manager of Jiangsu Daming, Jin Jiandong, Vice General Manager of Jiangsu Daming, as well as the relevant sales, production, quality control, production management, logistics department heads and staff representatives, and General Manager Zhang Feng made a mobilization speech.

This batch of products is the body frame structural parts for high-end new energy vehicles, and Jiangsu Daming will provide professional and efficient cutting and processing services, the products include 9 specifications, the total amount of millions of pieces. The project has high quality requirements, tight delivery schedule and large batch size, which puts the company’s processing capability to the test. Jiangsu Daming has set up a special project team, which has greatly improved its production capacity by formulating standardized process flow and optimizing tooling and fixtures, and is now able to mass produce according to customer demand. The project is expected to last until April 2020, with guaranteed supply during the Spring Festival.

General Manager Zhang Feng emphasized the significance and importance of the project in his speech, hoping that through this project to further improve the quality and skills of employees, the level of operation of the project team, processing quality and efficiency, and ultimately enhance the company’s ability to serve large projects. He asked the technical, production, logistics and other departments to work closely together to ensure the successful completion of the supporting services.

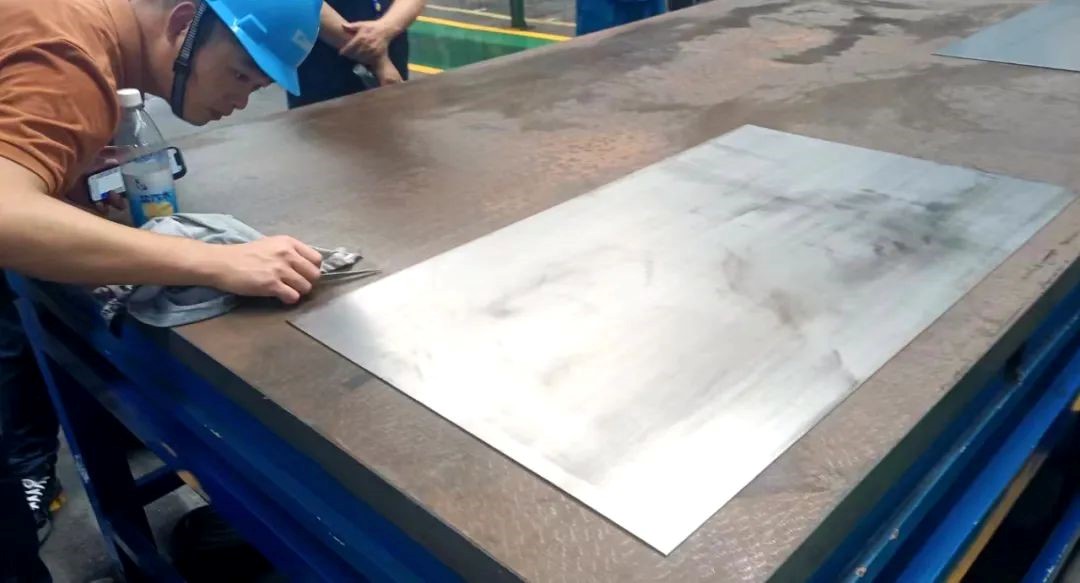

Daming Hubei processing center exquisite flat steel batch supporting passenger car beam (2019)

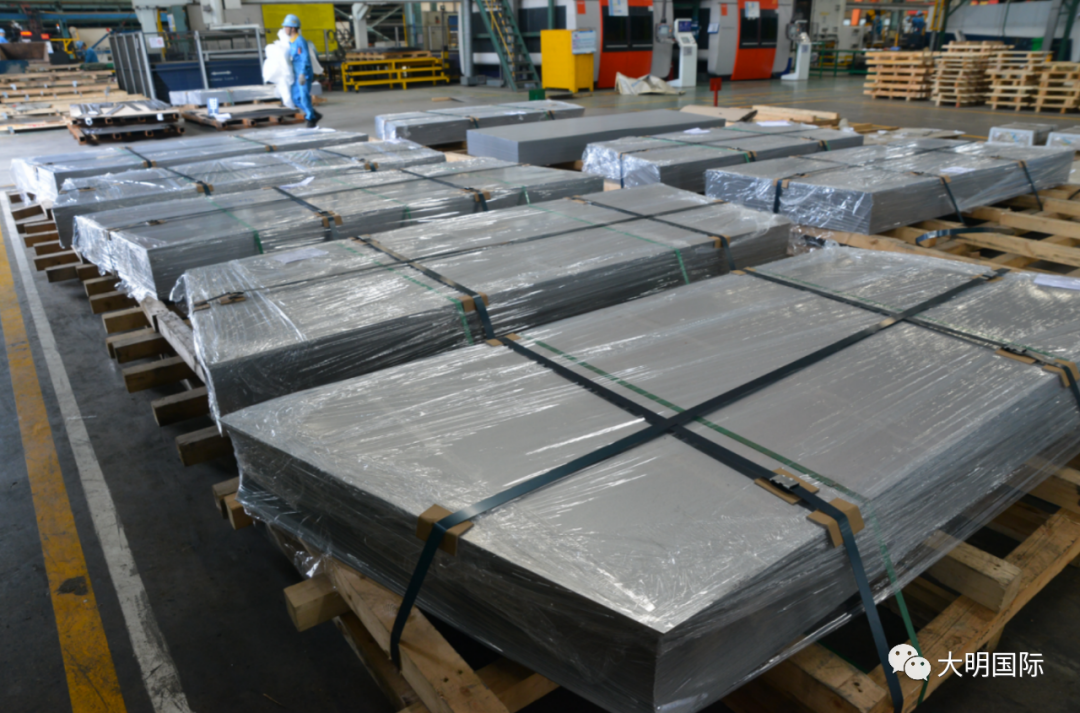

Recently, Daming Hubei Processing Center received a batch of orders for automotive beam flat steel, which requires processing WL510 5.0/6.0*1500*C automotive beam steel coils into 5*312.5*1180 and 6*207*760 flat steel, which is matched with a large passenger car plant as the main beam of the car. Daming Hubei Daming Center provides customers with high-quality and high-precision flat steel products by using high-strength steel flat steel line, and the finished products are also packaged with exquisite moisture-proof paper. Daming Hubei processing center flat steel products not only improve the customer’s production efficiency, but also help the customer to improve the quality of the product, the customer gave a good review, said that it will be a long-term and stable cooperation.

Exquisite flat steel products

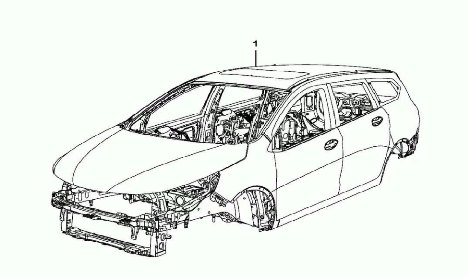

Schematic diagram of passenger car frame beams