Echipamentul medical pentru calitatea materialului din oțel inoxidabil, cerințele de precizie sunt foarte ridicate, Daming se bazează pe avantajele resurselor, comunicarea strânsă cu clienții, analizează nevoile lor și recomandările vizate. Departamentele de marketing și tehnologie de producție lucrează în strânsă colaborare și, în cele din urmă, completează serviciile de prelucrare și furnizare pentru clienți cu o calitate și o cantitate ridicate.

Medical Steam Sterilizer

Daming Heavy Industry Heavy Precision Manufacturing Branch, together with Jiangsu Daming Machining Division, has provided a well-known domestic medical equipment enterprises with supporting services for the processing of medical steam sterilizer door stall parts, and the products have been shipped to the customer in batches for assembly. This batch of orders totaling 1600 pieces, the raw material for the 40mm, thickness 304 hot-rolled plate, involving surface oil grinding, plasma cutting, shaping, machining and other processing technology. Since this part is the appearance surface of steam sterilizer, it has very high requirements for the consistency of product size and surface machining pattern, and does not allow any scratches and bumps.

Relying on advanced equipment, and the third generation of ERP system support, Jiangsu Daming Machining Division, through the optimization of the processing process, integrated processing solutions, the product quality and quantity of the delivery of customers on schedule.

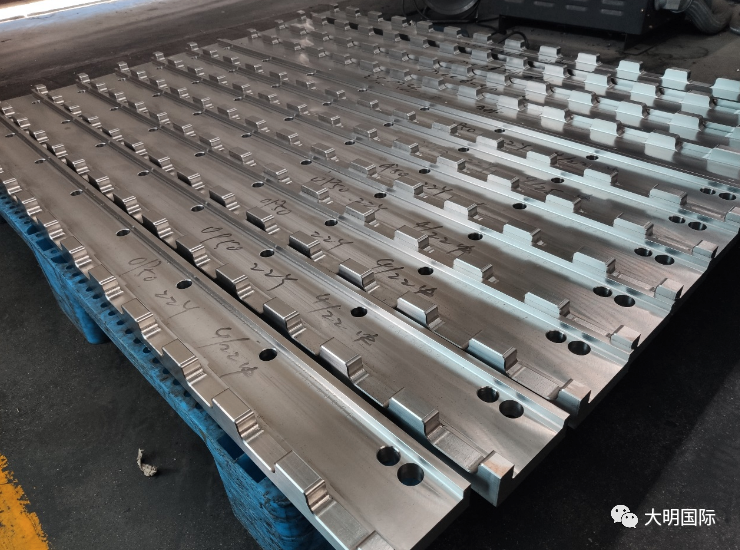

Since receiving the order in early June, the precision branch drew on the mature processing experience of Jiangsu Daming, made special tooling fixtures, and independently designed a special flow of wooden boxes to ensure the stability and reliability of the quality of the product in the process of machining, but also to help shorten the processing cycle. “High production efficiency, quality assurance synergy, cutting tools give strength”, up to now, the precision branch actively work together to cooperate with Jiangsu Daming to complete the delivery of 200 pieces of products, to alleviate Jiangsu Daming machining scheduling tight processing problems.

Relying on the advantages of the group and advanced equipment, the future Daming will be more competitive in the integration of resources and fast delivery, the molecular companies work together to win-win, and continue to deliver reliable quality products to customers as scheduled.

Medical Sterilizer

The medical sterilizers produced by Daming Precision Technology for a medical equipment enterprise in Hangzhou have successfully passed the acceptance inspection and have been shipped. The dry mist hydrogen peroxide sterilizers and vaporized hydrogen peroxide sterilizers produced by this enterprise are widely used in the front line of the fight against the new coronavirus.

The supporting products are mainly made of 304 stainless steel cold-rolled material with a thickness of 1.5mm. After processing such as leveling, roll grinding, laser cutting, bending, welding, grinding and wire trimming, it is still necessary to carry out secondary welding and grinding on some plates before assembly. Due to the thin plate material, welding is easy to produce deformation, coupled with the customer’s high requirements for the appearance and dimensional accuracy of the equipment, Daming Precision Technology and production departments after careful discussion, research and testing, successfully completed the first 8 sets of test samples for the customer, and shipped successfully.

Since the resumption of work, Daming Precision Engineering epidemic prevention and production of both, joint medical equipment and environmental protection equipment enterprises have for the epidemic areas and hospitals around the epidemic-proof sewage disinfection tank, biochemical tanks and other products processing supporting services, with sufficient resources, advanced equipment and excellent technology to help fight the “epidemic” front line.

Medical glove printing and dyeing equipment

Seizing the opportunity and giving full play to the advantages of stock resources and processing equipment, Daming Tianjin Processing Center successfully won the bidding for the medical glove printing and dyeing equipment supporting project of a medical equipment enterprise in Tangshan. The steel grade involved is mainly 304 and 316L cold rolled stainless steel, with a total of 500 sets, weighing about 500 tons. At present, it has been scheduled and shipped in three batches.

Infusion equipment supporting

Daming Tianjin machining center and Jiangsu Daming teamed up to complete 100 pieces of membrane and shell flanges for the supporting devices of infusion equipment in the medical industry, and gained recognition from the customers.

It is understood that Daming Tianjin machining center contracted to support the medical industry 100 pieces of membrane shell flange, selected the thickness of 20mm 304 stainless steel, made by Jiangsu Daming machining center. During the processing, it involves laser cutting, leveling, machining and other processes. The customer has clear quality requirements for flatness, size and surface. In response to the customer’s specific quality standards for processing, Jiangsu Daming related production, technology, sales and other personnel to seriously review, disassemble the drawings, develop a practical process plan, interlocking, taking 25 days to complete this batch of orders and pass the customer’s inspection.

High-end Medical Vehicle

Hubei Daming has provided high-end stainless steel products for a large special vehicle modification enterprise, which has been well received by users. The supporting vehicles for the Xiamen Jinlong wagon modified vaccine carriers, mainly used in major hospitals and emergency centers to transport short and medium distance vaccine preparations. Medical equipment for stainless steel steel material quality, precision requirements are very high, relying on the advantages of resources, Hubei Daming closely communicate with customers to analyze their needs and make targeted recommendations. Due to the tight delivery schedule, Hubei Daming marketing and production technology departments work closely together, and finally completed the processing and supply services with high quality and quantity. The customer is very satisfied with the cooperation with Hubei Daming, and said that it will start in-depth cooperation on other special-purpose vehicles later.

Vaccine Transportation Vehicle Interior

Matching CT machine detection guide rail realizes batch production

Since July 2016, Daming Heavy Industry completed the first set of medical equipment CT machine detection guide rail machining supporting, after 1 year of joint efforts with the customer, recently, Daming Heavy Industry processing of CT machine detection guide rail began to batch delivery.

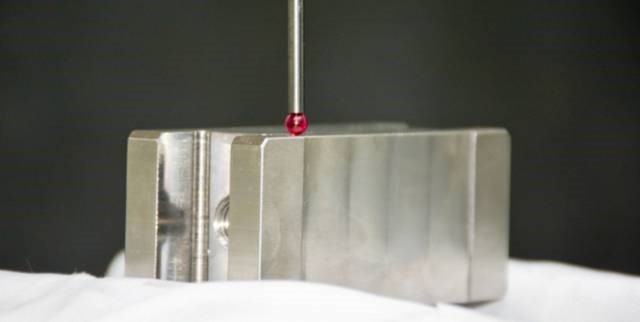

For the CT machine probe rail project, Daming Heavy Industry production and technical departments set up a special group, collaborate, for the matching of the product characteristics of the project, to determine the roughing, wire cutting, fine grinding, drilling and milling, finishing and clamping and other machining processes. The medical equipment has very high requirements for the matching precision, which requires the precision error to be less than 1µ (0.001mm). Daming Heavy Industry’s high-precision, flexible German Heath vertical turning and milling composite center and Zeiss coordinate inspection equipment provide a strong hardware guarantee for product processing and inspection; while the scientific specifications and rich experience in process control, assembly and debugging, and quality control supervision and inspection provide software support for product quality. At present, the machining process of CT machine probe guide is very stable and has been realized in batch.

It is reported that Daming Heavy Industry has processed more than 100 sets for this CT machine upper and lower detection guide rail project. Due to the maturity of Daming Heavy Industry’s processing and supporting program, from the incoming material to the processing to the overall assembly, which can be directly installed and used when delivered to the customer, the customer expressed great satisfaction, and then determined that Daming Heavy Industry would provide the overall supporting services from material to processing and assembly from 2018 onwards, which includes upper and lower guide rails and two The supporting products include the upper and lower guide rails and four parts of the support block, and are assembled at Daming Heavy Industry before shipment.

Performs aperture processing on products

Products are subjected to three-coordinate inspection

Molded Products

Assembly Inspection

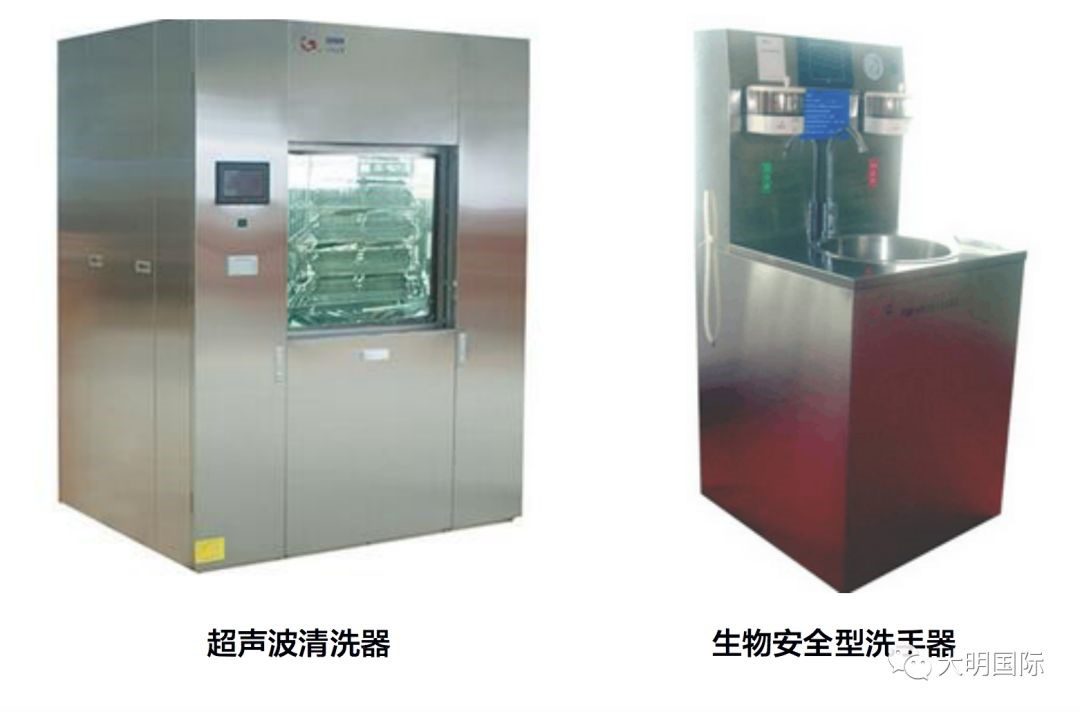

Ultrasonic cleaner, biosafety hand sanitizer

A well-known medical equipment company in Lianyungang, Jiangsu Province, donated to the Hubei Vulcan Mountain Hospital ultrasonic cleaner, biosafety hand sanitizer and other high-quality disinfection and sterilization equipment formally put into use, demonstrating the company’s great love.

Behind this batch of equipment put into use as scheduled, in fact, can not be separated from a group of silent Jingjiang Daming people. The manufacturing of this equipment requires 1.2mm-3.0mm 304/316L stainless steel as well as DC01 carbon steel cold rolled, Q345R6-10 container plate and other steel materials, with a material length of 1-12M, specifications involving more than 10 types and a quantity of more than 800 sheets. Multi-species, multi-specification and multi-batch orders have always been the difficulty of steel service, coupled with the supply chain problems caused by the epidemic, making customers anxious.

Supporting processing for medical and purification equipment

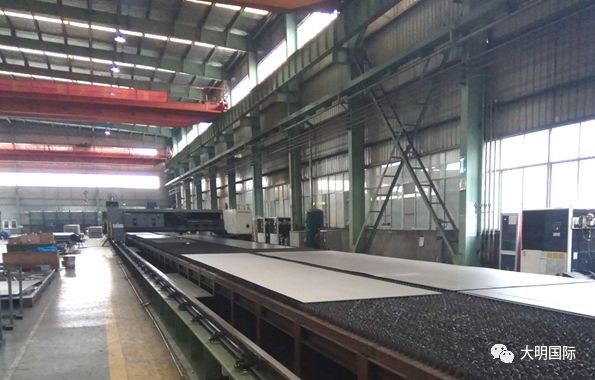

A large-scale medical and purification equipment enterprise entrusted Daming Hangzhou Processing Service Center with the processing of large-scale cutting and planing parts.

The product is a supporting assembly, the thickness of the material is 8mm, 10mm, 12mm, the longest length is more than 10 meters, and there are many sizes and specifications. After a number of preliminary consultations and drawing optimization, Hangzhou Processing Center finally determined that the 878 horizontal shear equipment first flat, and then by laser cutting, edge planing and other multi-process combination of processing, molding and then supporting the assembly.

This batch of products requires very high dimensional accuracy of the flat plate, Hangzhou processing center give full play to the Tanaka laser machine processing high precision, long length, wide range of features, production technicians in the processing of the perfect guarantee of the accuracy of the product, the customer’s technical staff recognized the level of processing.

Tianjin machining center high-precision processing supporting high-end medical equipment

Recently, Tianjin machining center provided a batch of supporting processing for a medical equipment enterprise in Beijing, the batch of products with more specifications, the number of more than 1,200 pieces, need to carry out laser cutting and bending processing. The customer has high requirements on processing accuracy and cutting seam, requiring the tolerance control in ±1mm, molding size and molding angle within the specified range.

Since the edge of the part is shaped, it is easy to cause deformation of the edge when bending; in addition, the thickness of the plate reaches 8mm and the length reaches about 2m, the extrusion deformation will occur at the bending line, which also increases the difficulty of bending. After the study of the process department, four cutting slits were added at the bending line, and then processed by 1600-ton bending machine, which avoided a series of problems such as extrusion and deformation of the workpiece, and met the customer’s requirements for precision, and was fully affirmed.

An enterprise after much Daming big visit, decided to commission Daming Tianjin machining center processing a batch of cutting parts supporting medical machinery.

This batch of products need laser cutting and bending two processes to complete. Customers have very high requirements for the accuracy of various holes and the precision of the cut seam, after the exchange of technical and field personnel, successfully solved a series of problems, smooth delivery and obtain customer praise, laying a good foundation for the later processing cooperation.