Caso de serviço:

Daming Hangzhou Processing Center Stainless Steel Products Service for Textile Enterprises Receives High Praise (2021)

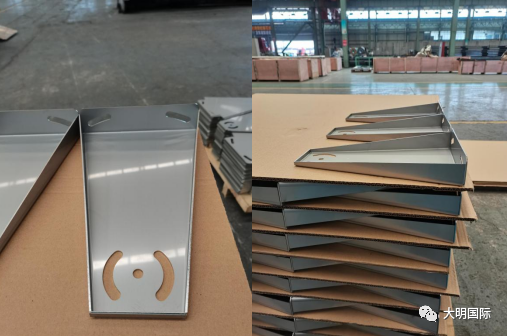

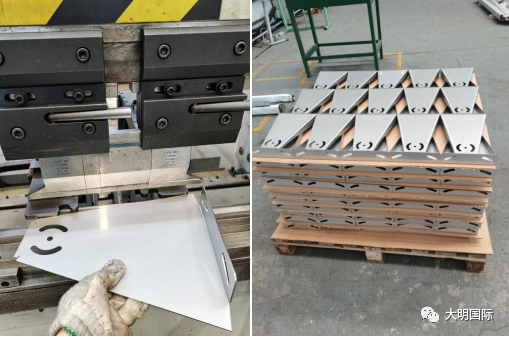

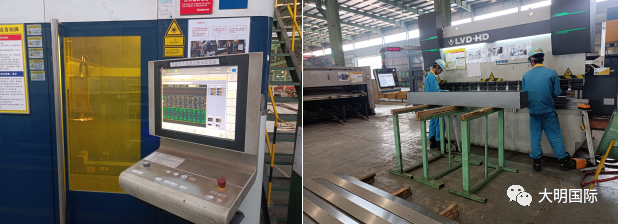

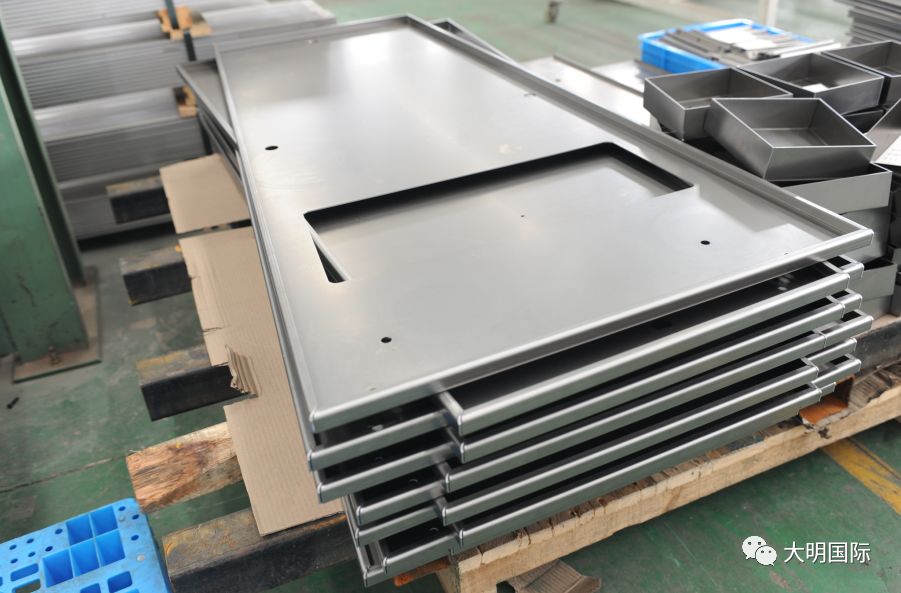

Hangzhou Daming received a batch of orders from textile enterprises. The order plate is 2mm thick 304 stainless steel, involving cutting and bending process. Due to the high requirements of this order, Hangzhou Processing Center effectively reduces the positioning and dimensional errors by fiber optic cutting with Thruflex equipment to ensure the required cutting accuracy of the product.

In addition, the bending pattern of this order is special, containing beveled edge bending, which requires higher dimensional accuracy for bending. According to the special characteristics of the graph, the production department of Hangzhou Processing Center chose the 100T bending machine forged by Huang forging for production. Yellow forging 100T bending machine has two independent backstop (backrest), according to the needs of individual back and forth, left and right movement, effectively reducing the dimensional error of the beveled edge bending, and ultimately the customer highly praised this batch of goods delivered.

Hangzhou Daming multi-channel process supporting a well-known spinning machine enterprise (2021)

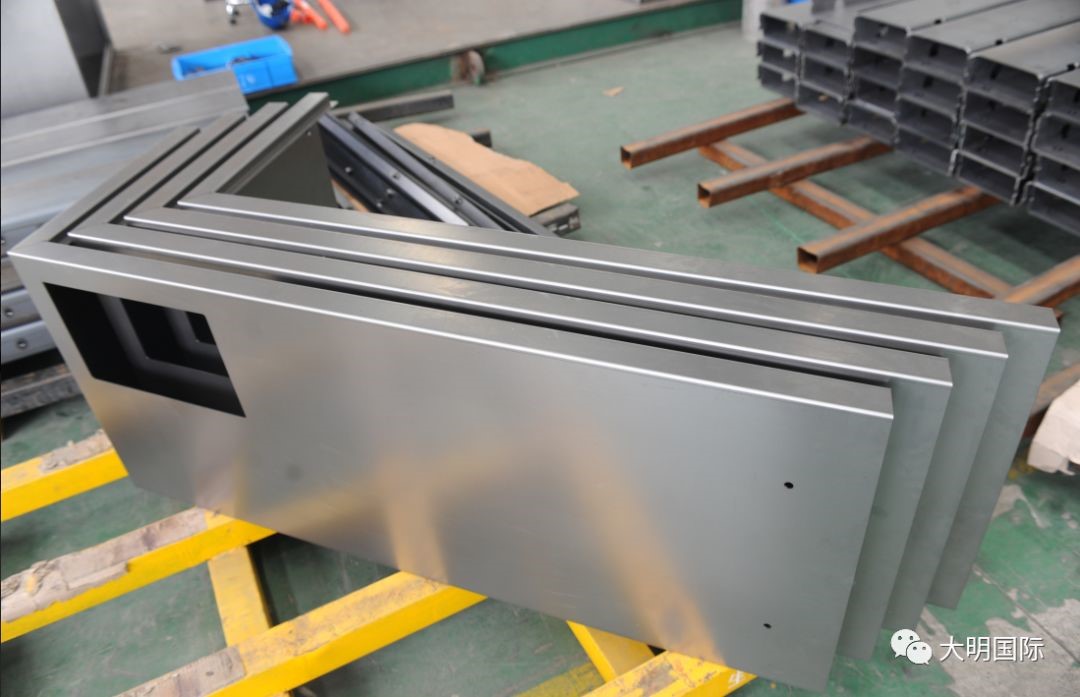

Daming Hangzhou Processing Center matched a batch of products for a famous spinning machine enterprise in Zhejiang Province, and the high quality control and efficient delivery of the products left a deep impression on the customer.

This batch of products need to go through many processes of leveling, cutting, bending, tapping and welding, Daming Hangzhou Processing Center provides one-stop service for the customer by virtue of its rich processing experience and perfect production and processing chain. At present, the first batch of 57 sets of products has been successfully completed and shipped to the customer 2 days in advance, which greatly saves the customer’s subsequent processing cycle, and the customer is also very satisfied with the processing quality of the products and said that it will add more than 100 sets of spinning machine product orders again.

Daming Hangzhou Processing Center has enough experience in deep processing for spinning machine enterprises (2021)

Daming Hangzhou Processing Center again successfully matched 99 sets of spinning machine products for a famous domestic spinning machine enterprise, which strengthened the customer’s adhesion and won the customer’s praise.

This batch of orders need to go through a number of processes, such as leveling, cutting, bending, leveling, tapping, welding, etc. With the “one-stop” service, rich processing experience and perfect equipment processing capacity, Daming Hangzhou Processing Center continuously improves the processing efficiency, which is highly recognized by the customer, and deepens the customer’s trust in Daming Hangzhou Processing Center.

Corte

Bengding

Welding

Transportation

Complementary products

Overcoming problems and improving efficiency, Daming Hangzhou Processing Center has reached a record high in supporting textile machinery (2020)

At the beginning of July, Daming Hangzhou Processing Center received an additional order from a textile machinery customer, from the first batch of 40 sets to 136 sets, and the monthly business volume was close to the limit of the processing center’s production capacity (the theoretical production capacity of a month is about 100 sets.) Hangzhou was already in the summer heat in July, and the surge of the order added a severe test to the production line. Daming Hangzhou Processing Center finally through the efforts of all staff, the actual completion of the July spinning machine orders 117 sets, more than 84 sets in April, 33 sets, processing efficiency from 3 sets a day to 4 sets a day level, in time to meet the customer’s deadline requirements.

Customers require a single month’s supply must reach more than 100 sets, the production department is anxious to customers’ urgency, the production task for the breakdown of refinement, the first process of cutting the material to put forward specific requirements, two shifts of 12-hour shifts to open the full force of the implementation of staggered meals, dinner, the weekend shift implementation of the interspersed rotation system to ensure that the equipment is 24 hours without stopping; welding process due to the shortage of manpower, and in a timely manner with the sister units Daming Due to the shortage of manpower in the welding process, the company communicated with the sister unit Daming Processing Center in time to get the support of personnel, realizing the “interoperability of personnel and business linkage”, which reflects the important role of the group’s linkage mechanism.

The temperature in Hangzhou in July is hot, the highest temperature has reached 36 ℃, cutting material personnel sweating to rush orders!

Molding process using “small, fast and precise” bending equipment to rush orders.

Daming supporting spinning machine spray equipment is highly praised (2019)

Recently, the spray tanks contracted by Jiangsu Daming and processed by Daming Precision Industry have been shipped and highly recognized by customers.

It is understood that the processing of the spray tank is supporting the textile machinery to deal with the residue of the previous process cleaning equipment, a total of 4 sets, the delivery period of only one week. Adopting 316L material with thickness of 2mm, the processing involves leveling, laser cutting, bending, filming and other processes, as the exposed surface needs to be single-sided film. Facing the situation of high product quality requirement and tight time, Daming production, technology and sales coordinated with each other and took the advantage of imported equipments and mature processing experience, and finally satisfied the customer’s requirements smoothly and got good comments.

Daming’s integrated matching service for the spinning machine industry steps into a new stage (2019)

Recently, the first batch of orders for a leading textile machinery enterprise in Zhejiang Province, jointly developed by the Market Development Department and Hangzhou Processing Center of Daming Group, were successfully delivered, which marks that the integrated distribution service of Daming Group in the textile machinery industry has entered a brand new stage.

This time, Daming provided the textile machinery enterprise with a complete set of sheet metal parts for the twisting machine. As the product subsequently involves surface coating and overall assembly processes, the surface flatness, hole spacing accuracy and edge smoothness are directly related to the production cycle and service life of the final product, so in addition to the strict requirements for the delivery date, the pass rate of all product sampling needs to reach over 99%. After continuous research and debugging between the market development department and the production and technical departments of Hangzhou Processing Center, relying on advanced processing equipment and rich processing experience, Daming successfully delivered the order and all the products passed the inspection at one time.

In recent years, the textile industry represented by chemical fiber and non-woven technology has been developing well, which drives the growth of textile machinery industry. Relying on its own advantages, Daming Group provides textile machinery manufacturers with a full range of integrated supporting services for dyeing and finishing equipment, washing equipment and twisting system. With nine continuous processing platforms and its own logistics services, it can effectively reduce customers’ production costs, compress the production cycle, and help customers enhance product competitiveness.

The continuous expansion of business in the textile machinery industry also benefits from the collaborative and focused development of the Group’s Market Development Department and Publicity and Planning Department. From training at industry conferences to on-site technical support for enterprises, and from material preference to optimization of processing and production, Daming’s strengths and service advantages have been recognized by more enterprises, and at present, Daming has been providing supporting services for well-known enterprises in the industry.

High-quality materials, high-quality processing, collaborative development, consulting services, Daming join hands with the textile industry and China’s manufacturing industry to grow together.