A Daming tem experiência no processamento e apoio de equipamento marítimo, baseando-se na rica equipa de produção e serviço, e depois nas equipas de vendas, tecnologia, produção, qualidade e outras equipas de cooperação multipartidária. Atualmente, a Daming tem fornecido pacotes de alta qualidade para clientes da indústria marítima, tais como anteparas interiores de navios-tanque de produtos químicos, a maior estrutura de estacas sólidas (caixa de velocidades) de navios de instalação de energia eólica offshore, torres de depuração marítima, tanques de combustível marítimo, etc.

Análise de casos:

Torre de depuração para navios da Yara Marine Technology (YMT)

Em 15 de janeiro de 2019, a Daming Heavy Industries (DHI) entregou com sucesso o primeiro conjunto de torres de depuração marítima offshore de apoio à YMT, e esta entrega é um marco importante para a DHI no serviço de processamento de produtos de torres de depuração marítima.

A YMT é um fornecedor de serviços integrados de dessulfurização e desnitrificação (FGD) que opera a nível mundial, com mais de um milhão de horas de funcionamento fiável para mais de uma centena de armadores em todo o mundo. No domínio do purificador de dessulfurização marítima, a YMT sempre teve a vantagem dominante e a liderança tecnológica no mercado.

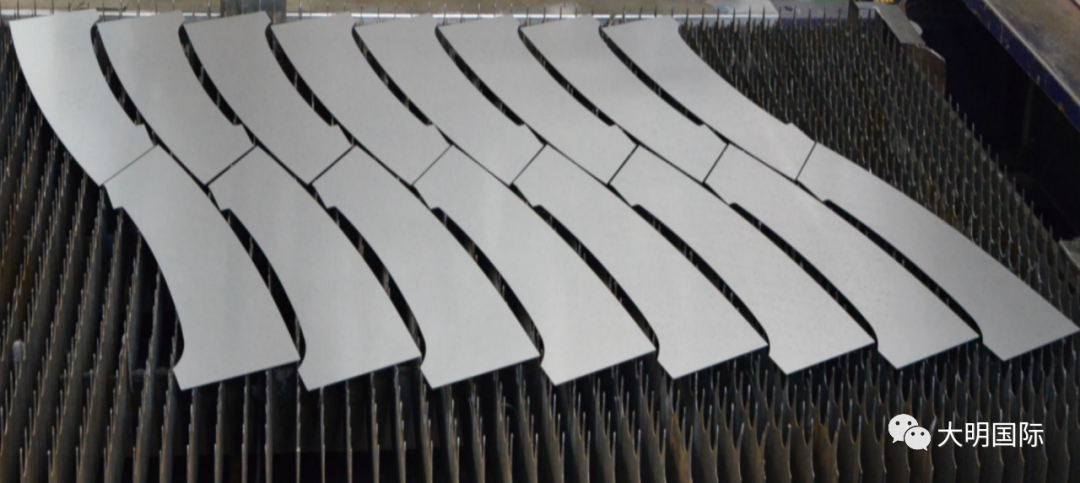

Como principal equipamento de proteção ambiental no domínio da navegação marítima, a torre do purificador de dessulfurização marítima é feita de uma liga de alta qualidade à base de níquel, cujo fabrico é difícil e arriscado. A Daming Heavy Industry superou muitas dificuldades técnicas durante o processo de produção, como a deformação da soldadura, as juntas de cilindros de paredes finas são fáceis de deformar, etc. Através dos esforços conjuntos de todos os membros do projeto e da luta dia e noite, o primeiro conjunto de torres de lavagem foi entregue um mês antes do previsto.

Os representantes do cliente e do armador reconheceram a eficiência e o profissionalismo da Daiming Heavy Industry e expressaram a sua forte vontade de cooperação a longo prazo. Atualmente, os produtos subsequentes de grande volume estão a ser produzidos de forma ordenada na oficina da Daming Heavy Industry.

Revisão de casos:

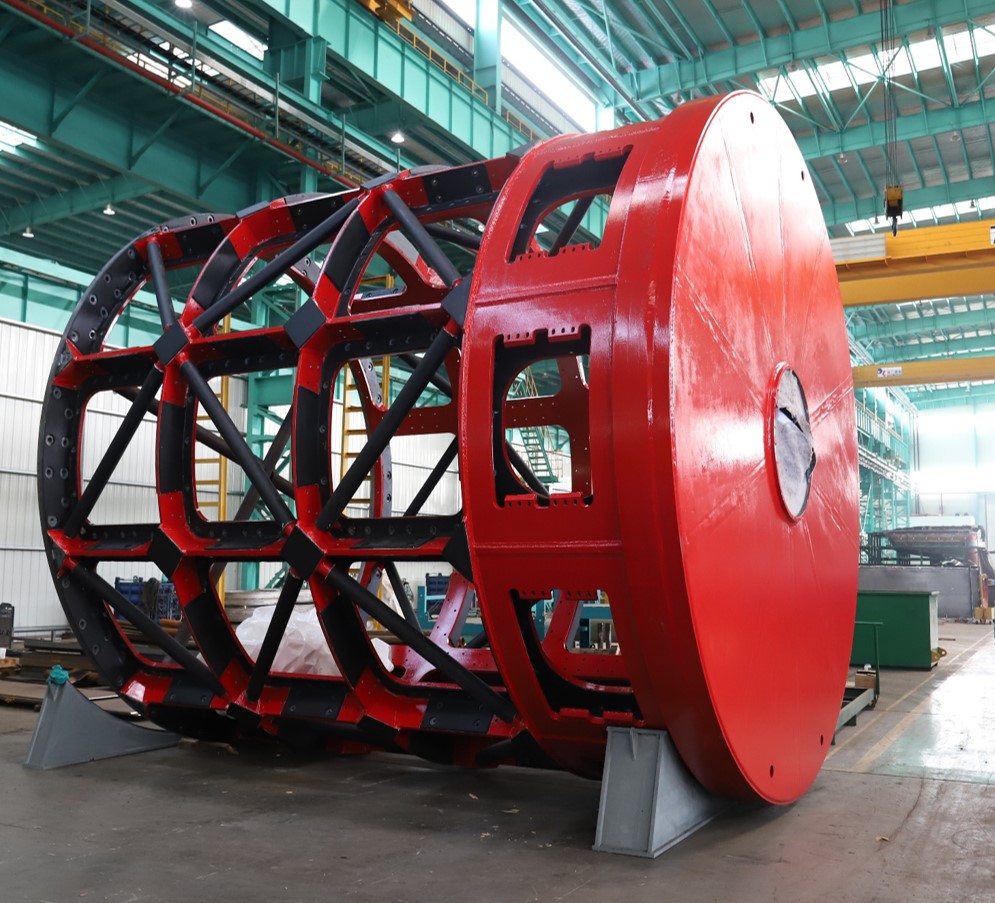

Entrega bem sucedida do maior navio de instalação de energia eólica offshore do mundo e do primeiro navio de instalação de energia eólica offshore da China, o projeto de estrutura de estacas fixas N966

A Daming entregou com sucesso a maior estrutura de estacas fixas (caixa de engrenagens) do mundo para a Qidong COSCO Shipping Offshore Engineering Co., Ltd, marcando a entrada bem-sucedida da Daming no campo da fabricação de grandes peças estruturais mecânicas usadas em embarcações de instalação de energia eólica offshore.

O projeto do navio de instalação de energia eólica jack-up N966 da empresa europeia de armadores construído pela Qidong COSCO foi especialmente concebido para o transporte, elevação e instalação de turbinas eólicas offshore, peças de ligação e bases. Em comparação com os navios de instalação de turbinas eólicas jack-up existentes, o navio oferece uma melhor manobrabilidade; não só o navio poderá transportar WTGs e bases da próxima geração, como o maior espaço de convés optimizará o trabalho de instalação offshore e reduzirá o consumo de combustível e as emissões. O navio não só estará pronto para o futuro da energia renovável offshore, como também estará disponível para utilização na indústria do petróleo e do gás, bem como para a demolição de estruturas offshore.

A embarcação é composta principalmente por uma grua de estacaria de mais de 3.000 toneladas com uma profundidade de operação de mais de 80 metros, uma carga útil de cerca de 14.000 toneladas e uma capacidade de 110 pessoas. A embarcação está equipada com quatro estacas para manter condições de trabalho estáveis no mar e está equipada com um sistema DP2. O produto entregue desta vez é a estrutura de estaca fixa (caixa de engrenagens) para as quatro pernas de estaca do navio, 12 peças no total, com o peso de uma única peça a atingir 90 toneladas. A Daiming completou com sucesso o processamento de apoio deste projeto, tirando partido da capacidade de serviço único desde o fornecimento de material, corte, soldadura, tratamento térmico, maquinagem, pulverização, etc.

Revisão de casos:

Entrega com sucesso da nova torre de dessulfuração marítima da COSCO para a Daiming Heavy Industries.

Recentemente, a Daming Heavy Industry completou dois conjuntos de torres de dessulfurização em aço inoxidável para novos navios da COSCO do Nantong COSCO Group e entregou-os com sucesso ao proprietário do terminal de Zhoushan, e o quarto conjunto foi basicamente concluído no final de 28 de novembro. No dia 28 de novembro, o proprietário, a CLEAN MARINE e a COSCO reconheceram o nível e a capacidade de fabrico e apoio da Daming e apresentaram uma faixa para mostrar o seu apreço e encorajamento. encorajamento.

Durante o processo de produção, o departamento de produção da Daiming Heavy Industry conta com a rica experiência de apoio à torre de depuração, o departamento técnico para fazer um bom trabalho de regulamentação do processo de fabrico e a produção em conjunto com a dificuldade do produto na fase inicial da produção de um por um decomposição. Todas as partes do projeto no centro de processamento de Jiangsu Daming e Daming Jingjiang para corte e processamento, fluxo de alta eficiência para a próxima soldadura, círculo redondo, dobragem e outros processos, reflectindo plenamente as vantagens da colaboração em grupo. Como os produtos são todos de chapa fina de aço inoxidável de material especial, é necessário ter em conta a placa de parede e a placa inferior de soldadura de fácil deformação e outros factores, a Daiming Heavy Industry utilizou a soldadura automática por plasma, a soldadura de belas formas, a velocidade de soldadura rápida, a elevada eficiência.

Devido ao calendário apertado do proprietário do navio, face às elevadas exigências de qualidade e entrega, a equipa do projeto fez uma distribuição razoável de todo o progresso e superou as dificuldades com os esforços conjuntos. Foram necessários apenas 45 dias desde a entrada do material até à entrega do primeiro produto, completando uma série de processos desde a descarga, emenda e soldadura, dobragem, circunferência, montagem, perfuração, decapagem e passivação. A promoção bem sucedida deste projeto representa um salto na capacidade de apoio à produção da Daming Heavy Industry e estabelece uma nova referência.

Para além disso, a Daming também fez corresponder a antepara interior do maior navio-tanque de produtos químicos do mundo, com 49 000 toneladas de tonelagem, que foi processado com aço inoxidável duplex. Com base na vantagem regional do local do projeto e na forte vantagem de processamento alargado da Daming Heavy Industry, a Daming Heavy Industry forneceu aos clientes os seguintes serviços: "Remoção de desenho - remoção de material - biselagem - soldadura - dobragem - distribuição". -Soldadura - Dobra - Distribuição", todo o processo de serviços de apoio ao processamento profundo do "mordomo", mas também a maior tonelagem do mundo de componentes principais de petroleiros químicos de aço inoxidável da localização geral do caso clássico.

Estas realizações de apoio são o testemunho passo a passo da reputação de serviço da Daming na indústria naval e offshore, e é também o resultado dos esforços da Daming em aprofundar o sector. Quais são as vantagens competitivas diferenciadas da Daming no sector do equipamento de apoio à indústria naval e offshore?