As the global automotive industry accelerates its structural transition, Daming Group continues to strengthen its leadership in automotive stainless steel. Against a backdrop of sustained pressure in the domestic internal combustion engine (ICE) market, the company has delivered resilient growth, underpinned by clear strategic direction, differentiated product capabilities, and an integrated service model. These strengths position Daming Group to lead the next industry cycle in 2026.

Resilient Growth Amid Market Headwinds

In 2025, Daming Group’s automotive stainless steel business reached an important inflection point. Despite overall softness in the automotive market, the Exhaust Stainless Steel segment achieved annual sales exceeding 175,000 tons, representing a year-on-year increase of 16%. Performance surpassed internal targets and reinforced the stability and competitiveness of Daming’s core automotive business.

Momentum has continued into 2026. January automotive stainless steel sales exceeded 17,000 tons, up 43% year on year, marking a strong start to the year and providing solid visibility toward full-year objectives.

At the same time, sales of 201 series stainless steel reached a record high, reflecting the effectiveness of Daming Group’s diversified product portfolio and category-driven growth strategy. Together, these results further consolidate the company’s leading position in the stainless steel value chain.

Core Competencies in Automotive Stainless Steel

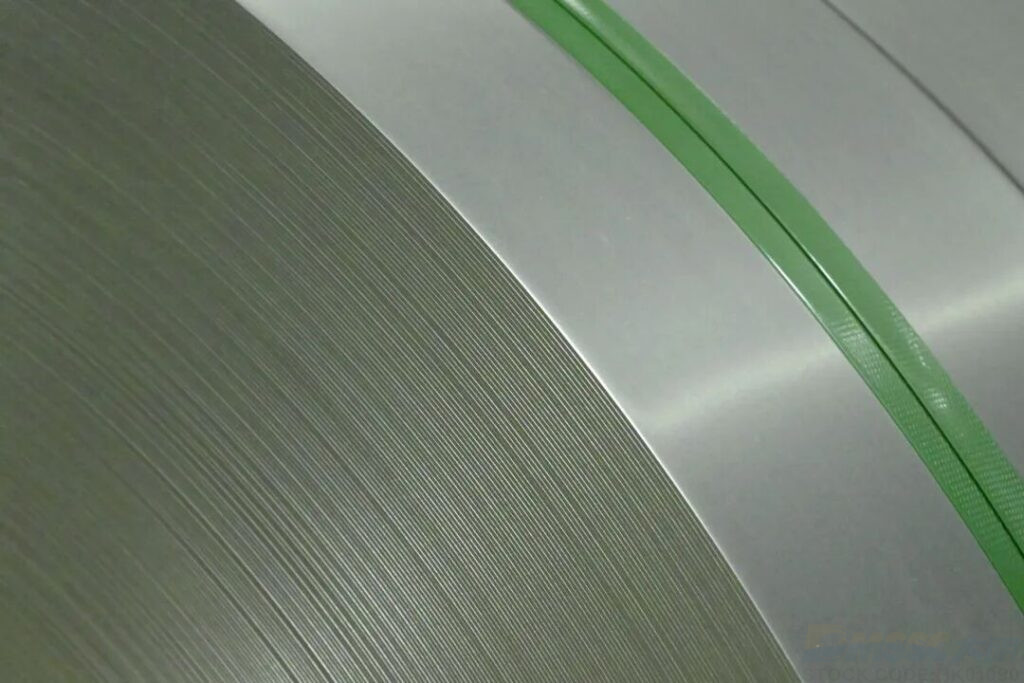

Automotive exhaust systems remain a critical application for stainless steel, with stringent requirements for high-temperature resistance, corrosion performance, and lightweight design. Leveraging deep industry experience, a nationwide distribution network, and stable upstream supply partnerships, Daming Group has established itself as a long-term, reliable supplier to automotive OEMs and Tier-1 manufacturers.

Quality remains a cornerstone of the company’s competitiveness. Daming Group operates rigorous quality assurance and process control systems to ensure consistent performance across all products. Through its integrated “one-stop” service platform, the company provides end-to-end solutions—from material selection and processing to logistics and delivery—tailored to the specific needs of automotive customers. This capability has enabled Daming to sustain leadership even as the ICE vehicle market faces structural challenges.

Aligning with Industry Evolution

As new energy vehicles (NEVs) continue to reshape the automotive landscape, Daming Group is proactively adapting its product and application strategy. While NEV penetration is altering material demand patterns, ICE vehicles continue to demonstrate stable demand in export markets, lower-tier cities, and niche applications, supporting long-term demand for high-performance stainless steel in exhaust systems and related components.

In parallel, industry trends such as lightweighting and vehicle premiumization are expanding stainless steel applications into fuel systems, body structures, chassis components, and NEV battery enclosures. Daming Group’s technical adaptability and application development capabilities enable it to capture opportunities across both traditional and new energy vehicle platforms.

Sustained Leadership in a Transforming Market

Daming Group’s performance in automotive stainless steel highlights its ability to identify high-value segments, build differentiated competitive advantages, and deliver consistent growth through market cycles.

Looking ahead, the company will continue to prioritize product innovation, service capability upgrades, and strategic collaboration with automotive customers. By deepening its presence across both ICE and NEV material systems, Daming Group is well positioned to strengthen its leadership while supporting the high-quality development of the global automotive industry.

As the industry enters a new phase in 2026 and beyond, Daming Group’s focus on execution, innovation, and customer value is set to remain a key driver of long-term growth and sustainable competitiveness.