Jingjiang Daming has once again demonstrated its industry-leading expertise in heavy equipment manufacturing by successfully entering the critical processing and shipment phase of a major project involving ultra-thick, high-strength specialty plates. This landmark project not only showcases Daming’s advanced manufacturing capabilities but also highlights its commitment to craftsmanship, innovation, and uncompromising quality standards.

Rising to the Challenge: Complex Processes Define Advanced Manufacturing

At the heart of this project lies an engineering and manufacturing challenge rarely encountered in conventional fabrication. The core difficulty began with processing steel plates that significantly exceeded typical thickness standards. Each step — from CNC cutting and precision beveling to heavy-duty rolling — demanded exacting control and coordination.

When plate dimensions surpassed in-house equipment limits, Daming’s project team swiftly implemented a carefully planned outsourcing strategy, integrating rigorous quality inspections and process controls. The result: outsourced rolling operations that met — and exceeded — the project’s stringent technical and safety requirements.

Excellence in Every Detail: Traceable, Certified, and Quality-Assured

For Jingjiang Daming, quality is not a goal — it’s a guarantee. Every processed plate undergoes traceable quality assurance procedures, culminating in the application of an internationally recognized classification society certification stamp before packaging. This stamp confirms compliance with global standards and offers customers tangible proof of Daming’s dedication to excellence, traceability, and quality assurance.

Ingenious Packaging: Engineering a Shield for the Steel Giants

Transporting ultra-heavy and oversized plates across oceans demands more than conventional logistics — it calls for engineering ingenuity. Daming responded by designing a highly specialized packaging solution, treating the shipping process as an extension of the production line, with the same degree of precision and care.

-

Custom Steel Frames: Tailor-made reinforced steel structures serve as heavy-duty carriers, securing plates during transport.

-

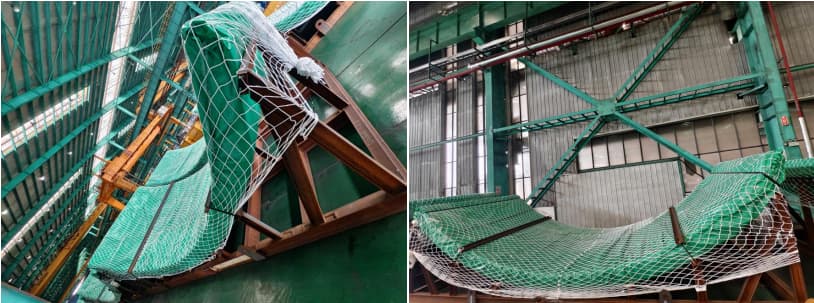

Layered Protection: Fumigated wooden planks separate each plate within the frames, preventing damage from friction and impact. Waterproof tarpaulins create the first layer of moisture protection, while high-strength mesh netting forms a secondary restraint.

-

Secure Fastening: A pressure plate is affixed atop each stack, tightly bolted to resist oceanic shocks and vibrations.

-

Data-Driven Packaging: Frames are organized under the “same drawing number, four sheets per package” rule. Each plate’s identification and drawing numbers are meticulously recorded to ensure full traceability and streamlined construction workflows at the destination site.

A Testament to Capability and Commitment

“This project is a comprehensive test of our technical and organizational strengths,” said the project leader at Jingjiang Daming. “We approach every detail with the mindset of a craftsman, ensuring that what we deliver is not only functionally sound but flawless in execution. The smooth advancement of this project once again confirms our leading position and core competitiveness in the high-end equipment manufacturing industry.”

As industries evolve and engineering demands grow more complex, Jingjiang Daming continues to push the boundaries of what’s possible — delivering not only heavy-duty solutions but also heavy-duty trust.