Lightweighting of commercial vehicles is an external requirement for the country to achieve “carbon peak” and “carbon neutral”, and also an internal driving force for enterprises to upgrade their products and enhance their competitiveness. However, as a variety of carbon steel – advanced high-strength steel, wear-resistant steel in the application of commercial vehicles, to varying degrees, facing a series of problems such as material selection and processing support.

Daming, as a leading enterprise of metal material processing and high-end manufacturing supporting services in China, has the whole process industrial chain of material processing, parts production and finished product manufacturing, professional and technical services, etc., and has formed a relatively mature “lightweight” supporting solutions for many years in the field of commercial vehicle supporting layout.

Daming is the first in the industry to create a new manufacturing model of “steel mill – processing center – manufacturing plant”, and provides downstream enterprises with “one-stop” solutions for material processing, parts and components, and manufacturing support by virtue of its competitive advantage in technological innovation. “Adhering to the idea of “lightweight”, it also integrates steel mills, professional institutes and its own resources to create a lightweight supporting platform for commercial vehicles in the whole process from design, materials to processing and supporting, which has been recognized by many representative enterprises up and down the industrial chain.

Daming adheres to the “customer-centered”, constantly innovates the service mode, strengthens the technology leadership, establishes joint R&D and application centers with Baowu and Hegang, provides EVI services to docking the end market, and constantly improves the technology and quality of parts and manufacturing support.

For example, in the field of wear-resistant steel, HISCO Handan Steel and Daming International, relying on the “HISCO – Daming International New Materials R & D and Application Center” technology platform, through the hardware configuration and soft strength of the Daming International, the processing of non-tempered wear-resistant steel open plate products with good plate shape, full stress release, high rate of success, which has caused a sensation in the industry.

In addition, in stainless steel materials, TISCO Group and Daming also jointly established the “Advanced Stainless Steel Materials State Key Laboratory Forming and Application Technology Research Center”, through technology leadership, joint innovation, and jointly promote high-end manufacturing.

Representative supporting products:

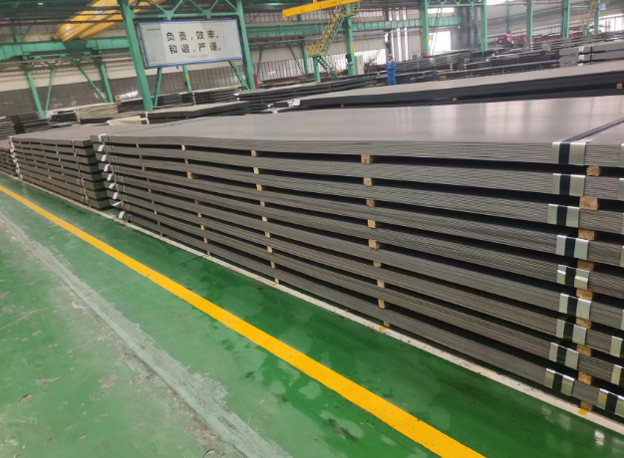

1、Girder steel

Daming’s bending and processing of beam steel is characterized by leading technology, individualization and high efficiency, especially in the continuous processing of super-long automotive beam steel, with outstanding advantages in straightening-straightening-cutting-bending-perforating-planing, and excellent control of straightness and internal stress of the products. The advantages of batching and high efficiency are also prominent in the processing and supporting of roll-type beam steel.

2、Daru és légi munkagépek gémjének feldolgozása

Crane boom steel has very high requirements for internal stress control. Daiming has formed systematic solutions for deformation control in the processes of unloading, bending, welding, etc., and effectively eliminates internal stresses and improves plate shape through precise heat treatment and leveling. Together with the advantages of advanced equipments, such as Sweden Usviken 3000T bending machine with maximum processing length of 15 meters and maximum processing thickness of 100mm, Daming has frequently received large orders for boom processing.

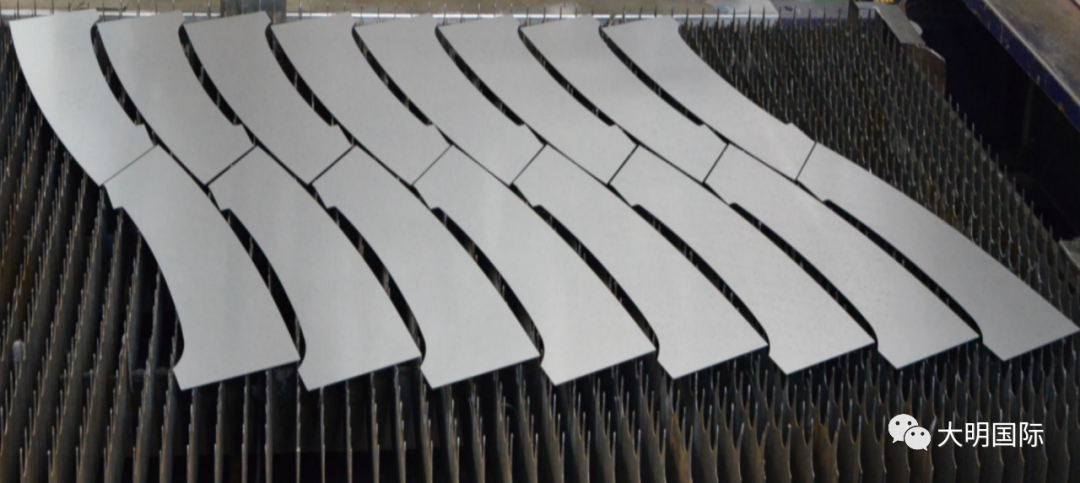

3、Wear-resistant steel (TP steel) coil leveling advantages.

With the strong growth momentum of China’s dump trucks, high strength, high wear-resistant, thin specification, processable compartment materials are more and more favored by the industry. Through the cooperation with HISCO Handan Steel, Baowu and other steel mills, Daming has launched the service mode of offline coil flattening of non-tempered wear-resistant steel, which is highly recognized by the industry for its good plate shape, full stress release and high rate of material formation, and has helped to promote the substitution of localization of this steel type.