Service Case:

Daming Import and Export Company supporting a food storage tank project of the Saudi government in the Middle East

Relying on the advantages of high-precision slitting and flattening equipments, Daming Import & Export Company has successfully supported a food storage tank project of the Saudi government in the Middle East.

Project supporting services

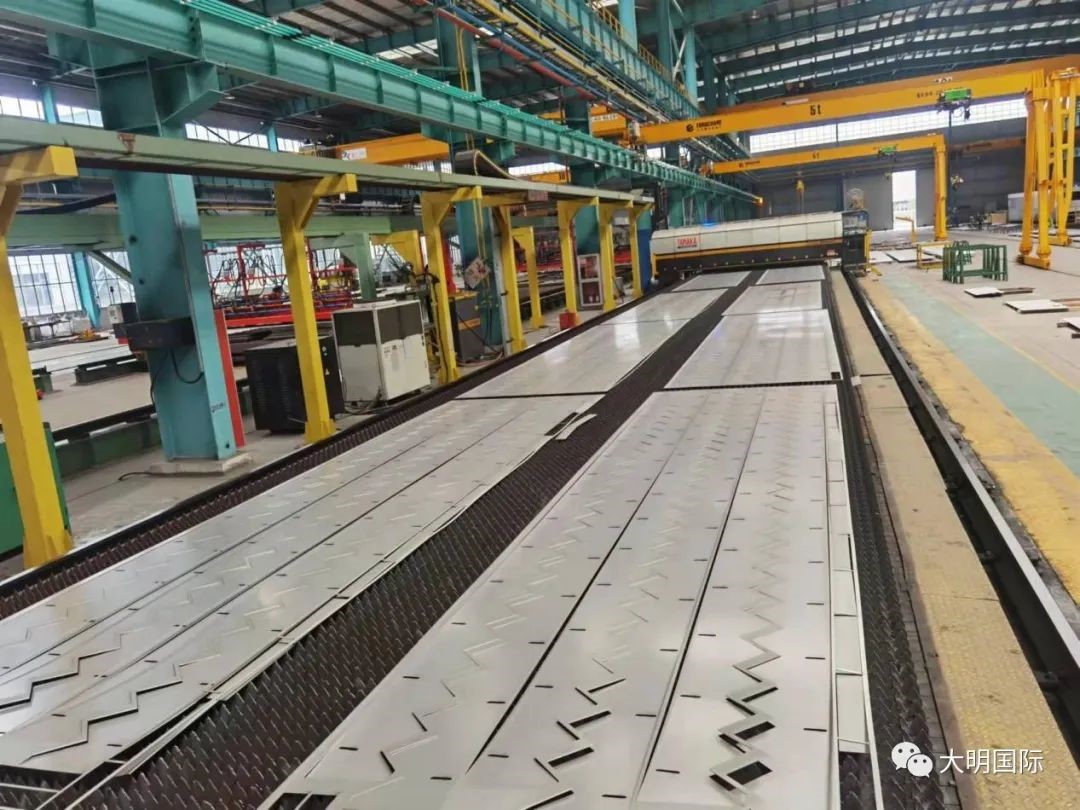

This time the customer material 200 tons, require the use of TISCO original 316L stainless steel material, involving many specifications, size miscellaneous, and also put forward high requirements for processing accuracy.

In response to the customer’s needs, Daming Import & Export Corporation, relying on sufficient material inventory resources, as well as the advantages of precision slitting and processing, has solved the customer’s problem of high requirements for single specification order quantity and complicated specifications of the steel mill, and has effectively saved the processing cost. Meanwhile, during the processing, the flatness of the plate is controlled at 3mm/2m with high precision, which greatly facilitates the rounding, edge planing and welding process for the customer.

The successful matching for the Middle East Saudi Arabia customers further consolidates the influence of Daming’s industry services in the Middle East market, strengthens the confidence of Daming’s development in the Middle East market, and lays a good foundation for the expansion of the deep processing business in the later stage.

Daming import and export team will continue to work hard, digging deeper into the direction of tank matching, with advanced processing equipment, refined “one-stop” service to continue to win the recognition of more overseas customers, and further to obtain more industry and high-end users of trust.

Tai’an processing center cold rolled stainless steel limited width cutting, service food customers customized needs (2023)

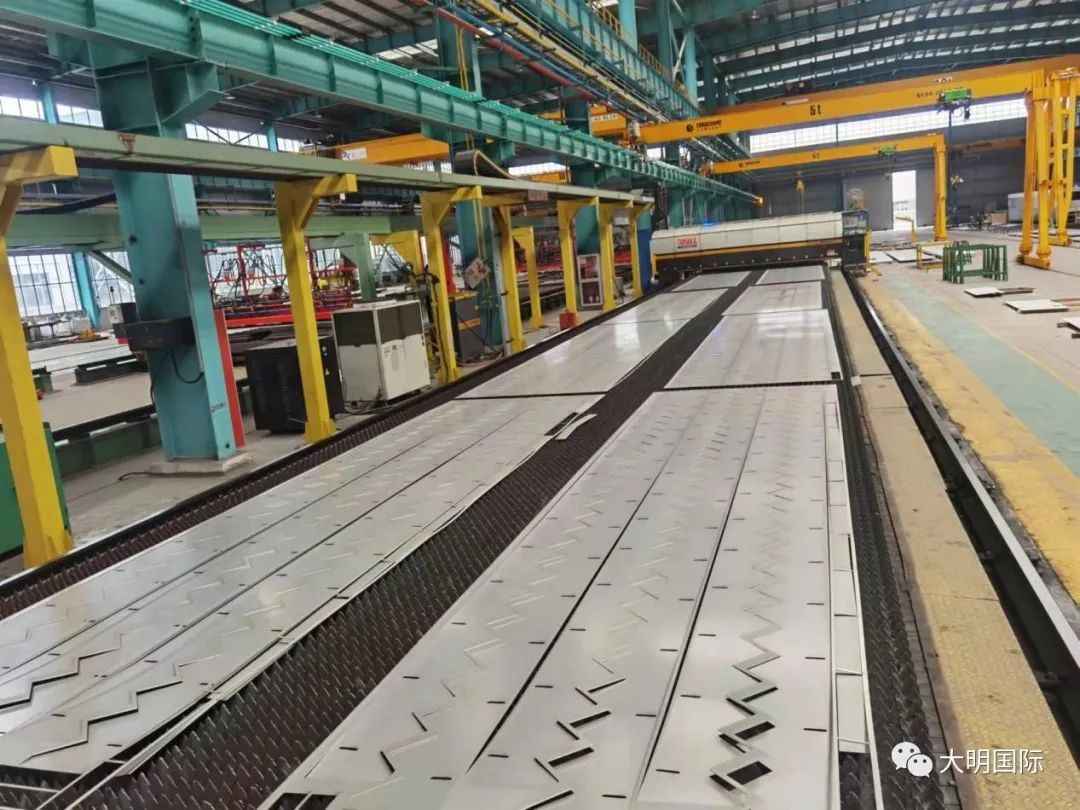

The cold rolled horizontal shear unit of Daming Tai’an Processing Center has successfully completed a batch of sheet leveling processing with a thickness of 3mm, a width of only 219mm, and a length of 4,940mm, which was delivered to the customer on schedule and fully recognized by the customer for its effectiveness in use.

Because the order is used in the food industry, the surface quality requirements are very high, and need to be padded flat, but the existing cold rolled cutting equipment in Tai’an processing center can only process a maximum width of 350MM.

In order to meet the customer’s demand for high quality, the project team quickly convened the cutting and processing technology backbone of the cross-cutting and leveling equipment to carry out a comprehensive transformation, and ultimately after the longitudinal shear to the cross-cutting and leveling success, highlighting the strong strength of the process technology of Daming, but also highly praised by the customer.

This process and technological innovation also laid a good foundation for undertaking more difficult processing orders in the future, while further motivating the Daming business team to forge ahead, innovate and provide high-quality services to more customers.

Hangzhou Daming multi-process supporting food machinery decorative plate (2023)

Daming Hangzhou Processing Center has processed several batches of decorative boards with high surface quality requirements for a well-known food machinery industry customer. The “one-stop” service with high quality, excellent cost and quick delivery has been well received by the customer: “The appearance is especially beautiful after the brushed treatment”.

Hangzhou Daming Processing Panel for Food Machinery Company (2023)

As the year is approaching the end, the demand of each customer for fast delivery is more and more urgent. In order to better meet the requirements of product quality and delivery, Daming dedicated service, sales and production, warehousing and other departments actively cooperate for a well-known domestic food machinery enterprises processing a number of panels highly recognized by the customer. The customer’s requirements for product quality are extremely strict, more than 70 kinds of specifications, which need to go through multiple processing of leveling, plate grinding, cutting and bending.

Hangzhou Daming Processing Center Serves Famous Food Machinery Enterprises (2022)

Daming Hangzhou machining center processed a batch of exterior panels for high-end large-scale food equipment for a long-term strategic partner – a food machinery enterprise, and the “one-stop” high-quality and efficient service from material, to surface grinding, precision cutting, bending and forming, and then to distribution won the high appreciation of the customer. We have won high appreciation from the customer for our “one-stop” high quality and efficient service.

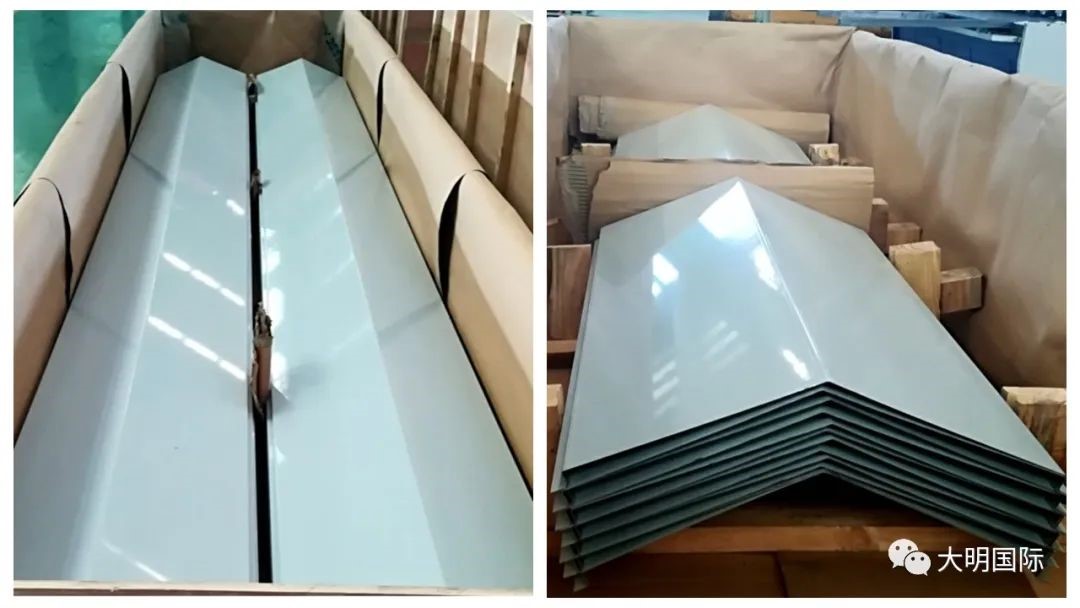

This batch of orders has more than 20 kinds of specifications, totaling more than 3,000 pieces, distributed in Sichuan, Guangdong and Shanxi Taiyuan and other projects. Due to the high requirements of the product on the surface of the material, Hangzhou machining center gives full play to the performance of Tanaka, Baichao and other machining equipment, and rich experience in service and other advantages to complete the work efficiently. In the transportation process, wooden box packaging was specially adopted to ensure long-distance transportation, and the customer feedback was “very satisfied” after the delivery.

Previously, the company also processed a number of emergency orders involving plate grinding, cutting and discharging of medium-thick plate. After understanding the situation, Hangzhou Processing Center responded quickly to the customer’s urgency and actively scheduled production; at the same time, it coordinated with the organization to increase the number of shifts in a timely manner, which ensured on-time delivery and saved valuable time for the customer in the logistics link.

The successive high-quality and efficient supply services not only further deepened the customer’s impression of Daming’s services, but also more comprehensively promoted the downstream owners of the enterprise’s visibility in the domestic market, and also laid a solid foundation for closer and stronger cooperation between the two sides.

Hangzhou Daming Processes Side Seal Plate for a Famous Food Machinery Enterprise (2022)

Daming Hangzhou machining center processed a batch of side sealing plate for a famous food machinery enterprise in China. The “one-stop” service with large platform, high quality and high efficiency helped the customer to solve the urgent problem.

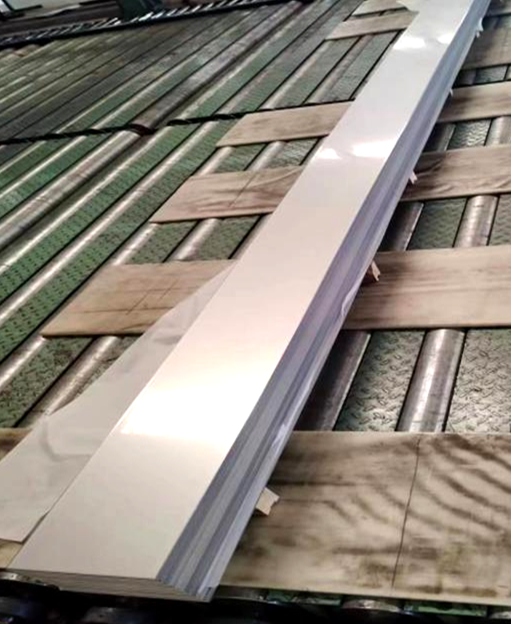

This batch of products need to be slitting, sanding, flattening, cutting multi-processes, product surface requirements NO.4 style. The size of the finished product is 12.5 meters long, most of the flattening equipment and cutting equipment on the market can not meet the processing requirements, and segmented processing will increase the cost and affect the appearance of the finished product.

Relying on the advanced processing equipment cluster, Hangzhou processing center gives full play to the advantage of large table of Tanaka laser cutting in Japan, the maximum cutting length can reach 33.5 meters, the maximum cutting width up to 4.1 meters, coupled with rich experience in service, the final high quality of processing is completed, and won a high degree of recognition from the customer.

Hangzhou Daming service export food and beverage equipment project (2022)

Daming Hangzhou machining center processed a batch of stainless steel products for a Zhejiang fluid equipment company for food and beverage equipment manufacturing for export to Africa. Due to the customer’s tight shipping schedule and urgent delivery date, Hangzhou machining center responded quickly and completed the work with high quality as scheduled and gained the customer’s recognition and thanks.

The order products involved in flattening, slitting, embossing and other processes, and the customer has strict requirements for precision, after careful discussion, through sales, planning, production of joint collaboration, and ultimately work overtime, before the delivery date to complete the processing of quality and quantity.

The staff of horizontal shear crew checked the products carefully to ensure the quality of the products:

Slitting crews complete production with high quality to ensure customer satisfaction:

Crews pack with care to show the quality of Daming:

Lentil punching flower process quality, beautiful appearance, export packaging:

It is Daming everyone in all aspects of the heart of the service, always maintain the “customer-centric” heart, in close collaboration between the departments to successfully complete the order, but also further highlights the professional strength of the Daming, and further in-depth cooperation with customers to lay a solid foundation.

Zhejiang Daming service a head dairy production base (2022)

Jiaxing processing center and a food machinery company in Zhejiang collaborated to complete a batch of orders for a Taiwanese group’s largest dairy beverage production base project. The project order involves hot rolled coil grinding, leveling, cutting, bending and other processes, with an urgent delivery schedule and strict control over quality and weight.

Jiaxing Processing Center planning, production, quality and other joint efforts, first of all, according to customer demand for the development of a detailed processing program, in the processing process, give full play to the performance advantages of advanced equipment, with a wealth of experience in machinery and equipment services, and ultimately a one-time successful completion.