Hubei Daming, one of Dmaing’s elven steel processong centers, has completed a major order for Russia’s first high-speed rail line, marking a significant milestone in international cooperation and infrastructure development. The company partnered with a leading domestic manufacturer to provide precision materials for this critical project, earning high praise from the client.

A Key Project for Regional Connectivity

The high-speed rail line, stretching from St. Petersburg to Vladivostok, is part of Russia’s long-term plan to enhance connectivity across its vast territory, particularly in the Far East. With Russia’s vast land area and growing need for modern transportation, this project represents a significant investment in both infrastructure and regional development. As China’s global influence continues to rise, this project is also a symbol of strengthening Sino-Russian ties and enhancing economic cooperation between the two nations.

The high-speed rail network, which is expected to significantly cut travel time and increase mobility, will serve as a catalyst for not just transport, but also economic integration in the region. By connecting key cities and boosting access to remote areas, the project will encourage investments, improve trade flow, and contribute to Russia’s modernization efforts.

Meeting Exacting Standards with Precision Engineering

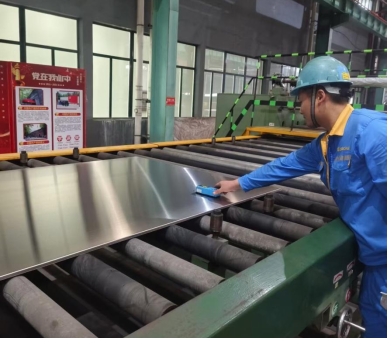

Hubei Daming was tasked with delivering plates ranging from 6-12mm in thickness, all while meeting stringent requirements for appearance, flatness, surface quality, and cutting precision. The high standards were critical because the materials would be used in the core infrastructure of the rail network, where even the smallest imperfection could compromise safety, durability, and operational efficiency.

The company’s ability to meet these high specifications is a testament to its advanced manufacturing capabilities, which leverage state-of-the-art technology to ensure top-tier results. High-speed rail projects require precision in every step of production — from material selection and processing to final delivery — and this collaboration with Russia’s leading rail infrastructure developers was no exception.

Hubei Daming’s team worked closely with the client to develop a tailored solution, focusing on specialized processes like cross-cutting, oil grinding, and laser cutting to ensure the materials met the precise dimensions and finishing requirements. After conducting small-batch trials and verification tests, the final product met all quality standards, ensuring that production timelines were met with minimal delays. This level of technical collaboration and innovation highlights the growing role of Chinese manufacturers in global high-tech infrastructure projects.

Fast and Reliable Delivery

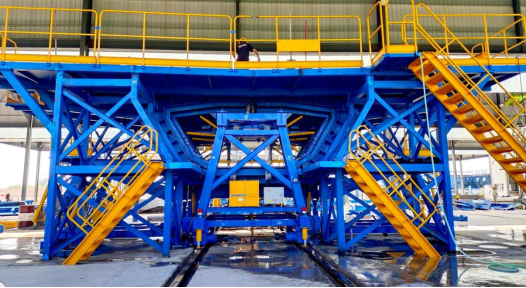

One of the standout aspects of this project was Hubei Daming’s ability to deliver the required 3,700 tons of materials in a compressed timeline of just four months. In the high-speed rail industry, where deadlines are often tight and every delay can disrupt the broader construction timeline, the ability to meet production and delivery targets is critical.

By leveraging its well-established production systems and deep technical expertise, Hubei Daming was able to fast-track production while maintaining the highest levels of quality control. This ensured that the customer could proceed with the project without any disruptions to the critical on-site construction schedules. The client expressed full satisfaction not only with the product’s quality but also with the reliability and punctuality of Hubei Daming’s delivery.

Industry Insights: The Growing Role of Precision Manufacturing in High-Speed Rail

The high-speed rail industry, which has seen rapid growth over the past few decades, requires the highest quality materials and components to meet the demands of modern transportation. High-speed rail systems are built with the goal of reducing travel times significantly, which requires advanced engineering, cutting-edge manufacturing techniques, and extremely precise materials.

In many countries, including Russia, China, and Japan, high-speed rail is seen as the backbone of future transportation systems, offering an environmentally friendly, efficient, and cost-effective alternative to air and road travel. As the industry evolves, it is increasingly reliant on materials like high-strength steel, aluminum alloys, and other advanced composites, all of which must be fabricated with meticulous precision.

China, as a global leader in high-speed rail technology, is playing a central role in setting international standards and providing the necessary expertise to support projects in markets worldwide. In fact, China has become one of the world’s largest producers of high-speed rail equipment and related materials, with companies like Hubei Daming leading the way in ensuring that each component meets international safety and performance standards.

Strengthening Long-Term Cooperation

This partnership between Hubei Daming and the Russian client highlights not just the company’s technological capabilities but also its ability to foster long-term relationships in key international markets. As China and Russia continue to deepen their economic and political ties, projects like the high-speed rail line will become increasingly important for both countries.

For Hubei Daming, this project is a stepping stone toward greater international expansion. By demonstrating its capacity to deliver high-quality materials on time and at scale, the company is positioning itself as a reliable partner in future global infrastructure projects. This success will likely open doors for additional projects along the Belt and Road Initiative and in other markets that are investing heavily in advanced transportation systems.

Looking Ahead: The Future of High-Speed Rail and Precision Manufacturing

The demand for high-speed rail infrastructure is expected to continue growing worldwide. According to industry reports, global investments in high-speed rail networks are projected to exceed $100 billion over the next decade. This growth is driven by the increasing need for faster, more efficient modes of transport to support urbanization and meet sustainability goals.

For manufacturers like Hubei Daming, the future is bright. The company is well-positioned to play a key role in supplying materials for these large-scale projects, as well as driving innovation in the manufacturing processes that support them. With a strong commitment to quality, precision, and efficiency, Hubei Daming is set to continue its success in global high-speed rail projects and other critical infrastructure initiatives.

A Global Partnership Story

This project serves as a powerful example of China’s high-end equipment manufacturing capabilities and its growing influence in international infrastructure. By providing high-quality materials and meeting stringent deadlines, Hubei Daming has proven itself as a key player in global transportation networks, setting the stage for continued growth in the industry. As the world embraces a future of faster, greener, and more efficient transport, Hubei Daming is committed to supporting the development of these transformative global projects.