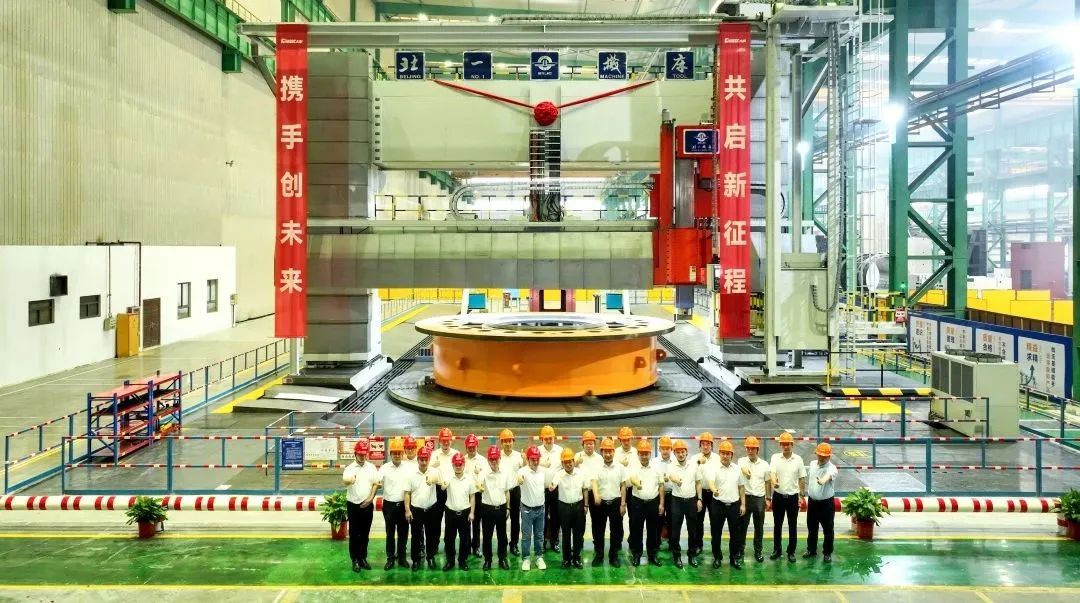

Start a new journey together, hand in hand to create the future! July 25, Daming Heavy Industry’s Beiyi CNC turning and milling machine tool production start-up ceremony was held in Daming Heavy Equipment Manufacturing Workshop.

The commissioning of the Beiyi CNC turning and milling machine tool is a heavy machinery processing equipment integrating machinery, electricity, liquid and other advanced technologies, which, as a big country’s heavy equipment, will become another treasure of Daming and further enhance the competitiveness of Daming’s equipment manufacturing.

Before the ceremony, Chairman Ruan Zhongkui of Jingcheng Machinery Electric and his team have visited the production workshop and logistics terminal of Jiangsu Daming and Daming Jingjiang base, and highly evaluated the scale of equipment, product type and service mode of Daming.

Mr. Keming Zhou, Chairman of Daming Group, expressed his warm welcome to the guests attending the ceremony, and expressed his heartfelt thanks to the support services of Beiyi Machine Tool. He pointed out that the two sides have complemented each other’s strengths and combined their strengths over the years, and have continuously deepened their cooperation and strengthened their interactions and exchanges, and signed a strategic cooperation agreement, which has successfully created a model of ecosystem cooperation. The cooperation with Beiyi machine tool will further expand the service scope of Daming Heavy Industry, so that the machining capacity has been qualitatively improved and the scale of expansion, but also highlights the determination of the two sides to deepen the strategic cooperation, which is a great gift for the 35th anniversary of Daming.

Beiyi XKA28120×200 CNC gantry boring and milling machine:

A super-heavy-duty machining equipment integrating machinery, electricity, liquid and other advanced technologies, it is mainly used for roughing and finishing machining of plane surfaces, rotary surfaces, curved surfaces, holes and grooves of large-medium-sized and large-weight parts of machine tools, engineering machinery, mining machinery and other manufacturing industries in multi-processes, such as milling, boring, turning, drilling, hinging, tapping, milling threads and so on.

Machining range:

The maximum passing width is 12.5 meters, the maximum passing height is 7.15 meters, the working platform is 11×20 meters, the diameter of rotary table is 10.5 meters, the maximum stroke of ram is up to 4 meters, the power of main motor is 105Kw.

Processing advantages:

According to the processing needs to configure a variety of accessory head, to realize automatic 720 × 0.5 ° indexing, a clamping can be simultaneously five surfaces for milling, boring, drilling, dumpling, tapping, etc., but also for oblique surfaces, oblique holes, two-dimensional surface, three-dimensional surfaces, holes inside the cavity of the parts and the plane in the narrow space for processing.

In addition, it is equipped with a rotary table with a diameter of 10.5 meters, which is capable of milling and turning workpieces. Its degree of automation and product strain are superior to other machine tools.