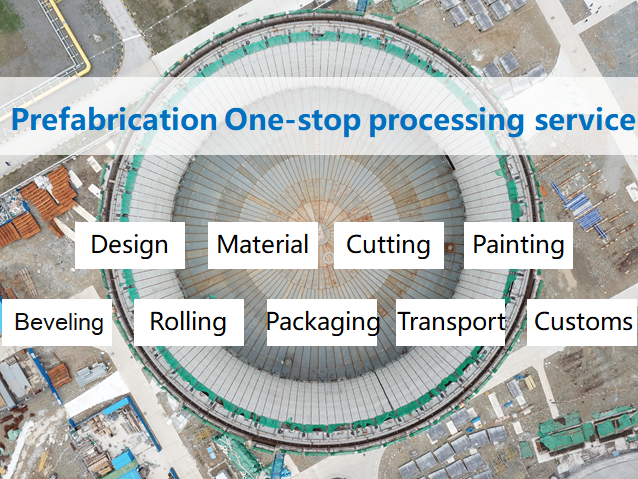

There are three major pain points in prefabrication for major projects:

First, insufficient processing capacity;

Two, too high labor costs at the construction site;

Third, too many project associates, affecting quality and efficiency.

Over the years, Daming has been focusing on the industry’s pain points, continuously strengthening its software and hardware capacity building, and is committed to building the world’s most competitive engineering project prefabrication service platform, providing professional full-process large-scale tank prefabrication service solutions for domestic and international projects, and helping customers realize light assets, fast delivery, high quality, and excellent cost.

01

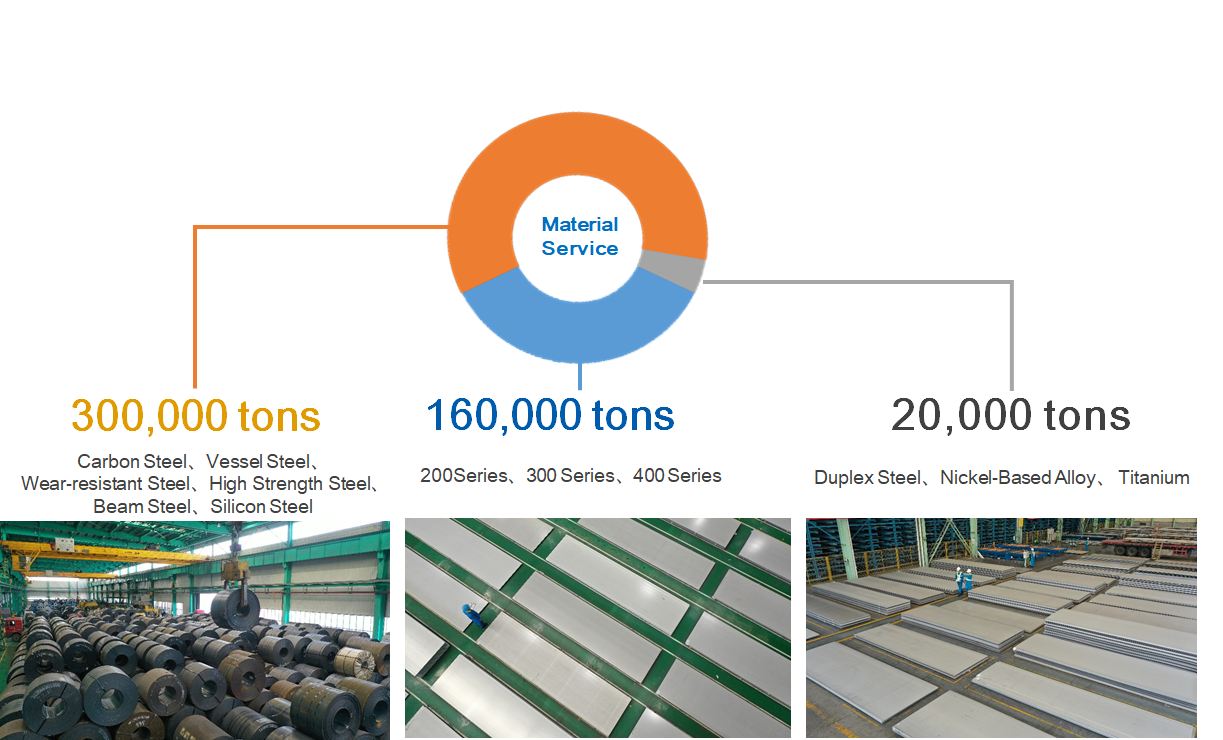

Material Guarantee:

Closely associated with the steel mills, Daming steel resources with large inventory, full range, excellent quality, the combination of spot and futures to ensure the stability of supply.

02

Prefabrication processing hard power:

Advanced equipment cluster, global leading processing equipment, assembly line operation.

▽Linsinger beveling processing line imported from Austria

▽Plasma or traveling flame and plasma cutting machine: fast cutting speed, not limited by the site

Plasma cutting equipment to process 9Ni plate to serve LNG cryogenic tanks

▽Rolling equipment: roll horizontal CNC rolling machine or vertical CNC plate rolling machine

Reduce packaging cost, roll with use, very suitable for small tanks and thin plate, of which Hausler circle round equipment up to 200mm thick molding (warm roll up to 300mm).

03

Soft power of technical service:

Relying on the accumulation of decades of processing technology and experience, and in-depth cooperation with steel mills, we provide the whole process of technical service support in the project, design and execution stages.

04

JIT logistics and after-sales:

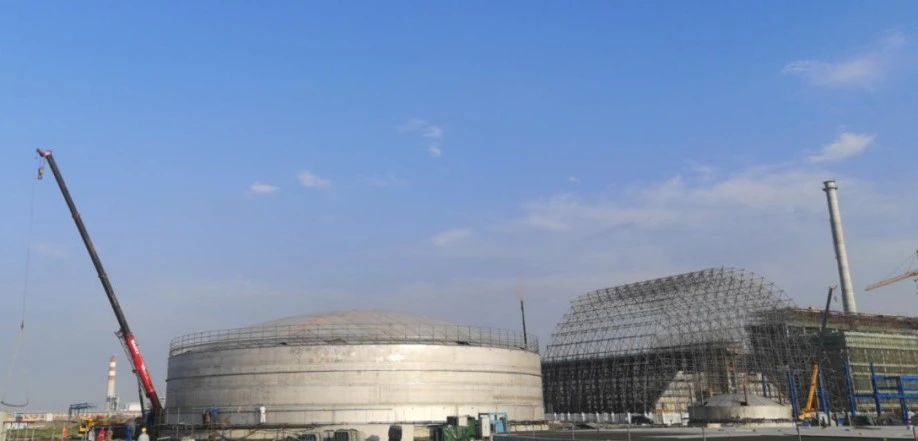

Service Cases of Daming’s “Full Prefabrication” Platform

Together with steel mills, international trading companies, design institutes and engineering companies, and taking advantage of the network layout and professional leveling platform, Daming has served many large-scale high-quality engineering projects at home and abroad, covering natural gas, non-ferrous metal mines, petrochemicals, new energy, bio-fermentation, food and beverage and other industries, and has been widely recognized for its ability to help solve the customer’s cost and efficiency problems.

In order to better serve the engineering projects, Daming will continue to optimize the manufacturing process and build more efficient assembly lines (on the basis of two fully automated edge milling lines in the Jingjiang base, one line will be added to each of the Tianjin and Taiyuan machining centers in 2023), and at the same time improve the domestic and overseas service network. At the same time, we will improve the service network at home and abroad. In addition to the two production and manufacturing export bases in Jingjiang and Tianjin for overseas projects, we will also set up service organizations in Europe, the United States, Singapore and other places to prepare for the establishment of an engineering service company, striving to provide optimal full prefabrication service solutions for large-scale global projects.

Examples of large storage tanks in various industries served by Daming

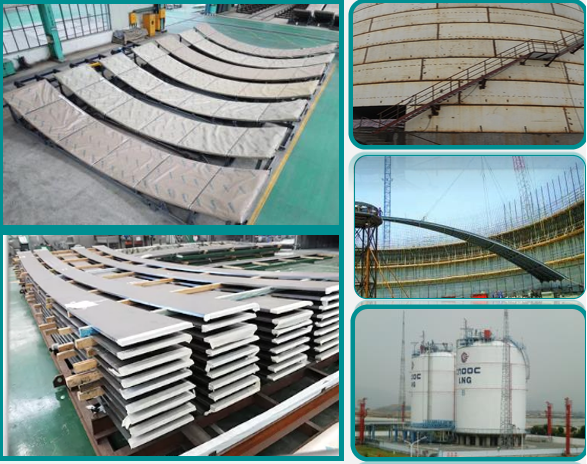

1、Complementary services for LNG industry

Daming LNG tank prefabrication has successfully served more than 40% of LNG receiving stations from Guangxi to Caofeidian in Tianjin. With the excellent 9Ni steel prefabrication processing, it has successfully cooperated with Baosteel and TISCO to support CNOOC’s LNG projects in Jiangsu Binhai, Hebei Tangshan and Shanghai Yangshan Port, and PetroChina’s LNG project in Jiangsu Nantong Rudong.

In addition, it has also cooperated with Nangang, Nippon Steel, Xingcheng Special Steel, etc. to support other LNG storage tank projects. As well as stainless steel and carbon steel outer tanks on LNG storage tanks, and LNG-related prefabricated panels, cryogenic tankers, gas tank support parts and so on.

2、Supporting services for petrochemical industry

A large-scale backbone enterprise in the field of petrochemical engineering and construction within the United Nations provided a total of more than 1,700 tons of prefabricated steel plates of tanks for PTA chemical raw material storage tanks of a base in Nantong, which were used for tank assembly and welding directly after arriving at the site after multiple processes such as leveling, cutting, edge planing and circle rounding, and the supporting tanks reached a maximum of 20,000 cubic meters.

In addition, TISCO also joined hands with PetroChina to support the tank prefabrication molding for the Anyue gas field project, to promote the new downstream application of 6 molybdenum steel plate and to complete the corresponding support.

Jointly with Chengdu Deep Cooling, Samsung Engineering and other well-known equipment engineering enterprises, to provide high-quality supporting services for the oil and gas industry, and has been highly recognized by the industry.

3、Supporting services for new energy industry

For the world’s largest solar thermal photovoltaic power generation project, “Belt and Road” key and highlight project – Dubai 950 MW solar thermal photovoltaic composite power plant project to provide solar thermal storage tank pre-fabricated steel plate SA516GR70 material processing support. Combined with Shanghai Electric and Baosteel, the company has successfully completed the processing of PT1, PT2 and PT3 with a total of more than 20,000 tons, relying on high-end equipment, technology and rich experience.

4、Matching Mining and Metallurgical Industry

Providing supporting equipment for Metso Otoutei’s large-scale container tank project will serve the world-class mega copper and cobalt mine in DRC, which is a model project of China-Africa cooperation and a good case study in the active African copper and cobalt market.

For Liqin Mining’s Indonesia OBI nickel and cobalt metallurgy project supporting 2,200 tons of stainless steel, duplex steel large tank prefabrication (316L), Daiming successfully completed duplex steel cone plate coiling through the first-class circle forming equipment HAEUSLER coiler imported from Switzerland.

5、Supporting services for the brewing industry

The Beibuwan New Material Company has provided more than 20,000 tons of stainless steel materials for the Luzhou Laojiao Brewery Project, which is a model project for improving quality and efficiency in the domestic brewery industry with a total investment of more than 7 billion yuan, and the excellent processing quality and distribution services have extended the service industry chain of the steel plant. At present, Daming has provided perfect stainless steel material processing and distribution services for many large-scale winery projects in China jointly with steel mills.

6、Supporting services for pulp industry

Daming has also joined forces with TISCO to provide ancillary services for ANDRITZ’s Brazilian pulp tank prefabrication project.

In addition, Daming also provides many biopharmaceutical and grain storage enterprises with prefabricated panel processing for large storage tanks and silos, and the products can be directly assembled at the site after edge shaving, which greatly prompts the efficiency.