Η Daming έχει την εμπειρία της επεξεργασίας και της υποστήριξης του θαλάσσιου εξοπλισμού, βασιζόμενη στην πλούσια ομάδα παραγωγής και εξυπηρέτησης και στη συνέχεια στις πωλήσεις, την τεχνολογία, την παραγωγή, την ποιότητα και άλλες ομάδες πολυμερούς συνεργασίας. Επί του παρόντος, η Daming έχει παράσχει πακέτα υψηλής ποιότητας για τους πελάτες της ναυτιλιακής βιομηχανίας, όπως εσωτερικά διαφράγματα χημικών δεξαμενόπλοιων, το μεγαλύτερο υπεράκτιο σκάφος εγκατάστασης αιολικής ενέργειας στερεό πλαίσιο πασσάλων (κιβώτιο ταχυτήτων), πύργους θαλάσσιων καθαριστών, δεξαμενές καυσίμων θαλάσσης και ούτω καθεξής.

Ανασκόπηση περίπτωσης:

Πύργος καθαρισμού για τα πλοία της Yara Marine Technology (YMT)

Στις 15 Ιανουαρίου 2019, η Daming Heavy Industries (DHI) παρέδωσε με επιτυχία το πρώτο σετ υπεράκτιων πύργων θαλάσσιων καθαριστών που υποστηρίζουν την YMT και αυτή η παράδοση αποτελεί σημαντικό ορόσημο για την DHI στην υπηρεσία επεξεργασίας προϊόντων θαλάσσιων πύργων καθαρισμού.

Η YMT είναι ένας παγκοσμίως δραστηριοποιούμενος, ολοκληρωμένος πάροχος υπηρεσιών αποθείωσης και απονιτροποίησης (FGD) με περισσότερες από ένα εκατομμύριο ώρες αξιόπιστης λειτουργίας για περισσότερους από εκατό πλοιοκτήτες σε όλο τον κόσμο. Στον τομέα των πλυντηρίων αποθείωσης πλοίων, η YMT είχε πάντα το κυρίαρχο πλεονέκτημα και την τεχνολογική ηγεσία στην αγορά.

Ως ο κύριος εξοπλισμός προστασίας του περιβάλλοντος στον τομέα της ναυσιπλοΐας, ο πύργος καθαρισμού θαλάσσιας αποθείωσης είναι κατασκευασμένος από κράμα υψηλής ποιότητας με βάση το νικέλιο, η κατασκευή του οποίου είναι δύσκολη και επικίνδυνη. Η Daming Heavy Industry ξεπέρασε πολλές τεχνικές δυσκολίες κατά τη διαδικασία παραγωγής, όπως η παραμόρφωση συγκόλλησης, οι αρμοί κυλίνδρων με λεπτά τοιχώματα είναι εύκολο να παραμορφωθούν κ.λπ. Μέσω των κοινών προσπαθειών όλων των μελών του έργου και του αγώνα μέρα και νύχτα, το πρώτο σετ πύργου καθαρισμού παραδόθηκε ένα μήνα νωρίτερα από το χρονοδιάγραμμα.

Οι εκπρόσωποι του πελάτη και του πλοιοκτήτη αναγνώρισαν ιδιαίτερα την αποτελεσματικότητα και τον επαγγελματισμό της Daiming Heavy Industry και εξέφρασαν την ισχυρή βούλησή τους για μακροχρόνια συνεργασία. Επί του παρόντος, τα επόμενα προϊόντα μεγάλου όγκου παράγονται με ομαλό τρόπο στο εργαστήριο της Daiming Heavy Industry.

Ανασκόπηση περίπτωσης:

Επιτυχής παράδοση του μεγαλύτερου στον κόσμο και του πρώτου υπεράκτιου σκάφους εγκατάστασης αιολικής ενέργειας της Κίνας N966 με σταθερό πασσαλοειδές πλαίσιο έργου

Η Daming παρέδωσε με επιτυχία το μεγαλύτερο υπεράκτιο σκάφος εγκατάστασης αιολικής ενέργειας στον κόσμο με σταθερό πλαίσιο πασσάλου (κιβώτιο ταχυτήτων) στην Qidong COSCO Shipping Offshore Engineering Co., Ltd., σηματοδοτώντας την επιτυχή είσοδο της Daming στον τομέα της κατασκευής μεγάλων μηχανικών δομικών εξαρτημάτων που χρησιμοποιούνται σε υπεράκτια σκάφη εγκατάστασης αιολικής ενέργειας.

Το έργο του σκάφους εγκατάστασης αιολικής ενέργειας N966 jack-up της ευρωπαϊκής πλοιοκτήτριας εταιρείας που κατασκευάστηκε από την Qidong COSCO είναι ειδικά σχεδιασμένο για τη μεταφορά, την ανύψωση και την εγκατάσταση υπεράκτιων ανεμογεννητριών, εξαρτημάτων σύνδεσης και βάσεων. Σε σύγκριση με τα υπάρχοντα σκάφη εγκατάστασης ανεμογεννητριών jack-up, το σκάφος προσφέρει καλύτερη ευελιξία- όχι μόνο θα μπορεί να μεταφέρει WTGs και βάσεις επόμενης γενιάς, αλλά ο μεγαλύτερος χώρος καταστρώματος θα βελτιστοποιήσει τις εργασίες υπεράκτιας εγκατάστασης και θα μειώσει την κατανάλωση καυσίμων και τις εκπομπές. Το σκάφος δεν θα είναι μόνο έτοιμο για το μέλλον των υπεράκτιων ανανεώσιμων πηγών ενέργειας, αλλά θα είναι επίσης διαθέσιμο για χρήση στη βιομηχανία πετρελαίου και φυσικού αερίου, καθώς και για την κατεδάφιση υπεράκτιων κατασκευών.

Το σκάφος αποτελείται κυρίως από έναν γερανό περιτύλιξης πασσάλων άνω των 3.000 τόνων με βάθος λειτουργίας άνω των 80 μέτρων, ωφέλιμο φορτίο περίπου 14.000 τόνων και χωρητικότητα 110 ατόμων. Το σκάφος είναι εξοπλισμένο με τέσσερα πασσαλοφόρα πόδια για τη διατήρηση σταθερών συνθηκών εργασίας στη θάλασσα και είναι εξοπλισμένο με σύστημα DP2. Το προϊόν που παραδόθηκε αυτή τη φορά είναι το σταθερό πλαίσιο πασσάλων (κιβώτιο ταχυτήτων) για τα τέσσερα πασσαλοπόδαρα του πλοίου, 12 τεμάχια συνολικά, με το βάρος ενός τεμαχίου να φτάνει τους 90 τόνους. Η Daiming ολοκλήρωσε με επιτυχία την υποστηρικτική επεξεργασία αυτού του έργου εκμεταλλευόμενη την ικανότητα παροχής υπηρεσιών μίας στάσης από την προμήθεια υλικών, την κοπή, τη συγκόλληση, τη θερμική επεξεργασία, τη μηχανική κατεργασία, τον ψεκασμό κ.ο.κ.

Ανασκόπηση περίπτωσης:

Επιτυχής παράδοση του νέου θαλάσσιου πύργου αποθείωσης της COSCO για την Daiming Heavy Industries.

Πρόσφατα, η Daming Heavy Industry ολοκλήρωσε δύο σύνολα πύργων αποθείωσης από ανοξείδωτο χάλυβα για νέα πλοία υπό την COSCO του ομίλου Nantong COSCO και τα παρέδωσε με επιτυχία στον ιδιοκτήτη του τερματικού σταθμού Zhoushan, ενώ το τέταρτο σύνολο ολοκληρώθηκε ουσιαστικά στο τέλος της 28ης Νοεμβρίου. Στις 28 Νοεμβρίου, ο πλοιοκτήτης, η CLEAN MARINE και η COSCO αναγνώρισαν το επίπεδο και την ικανότητα κατασκευής και υποστήριξης της Daming και παρουσίασαν ένα πανό για να δείξουν την εκτίμησή τους και την ενθάρρυνσή τους. ενθάρρυνση.

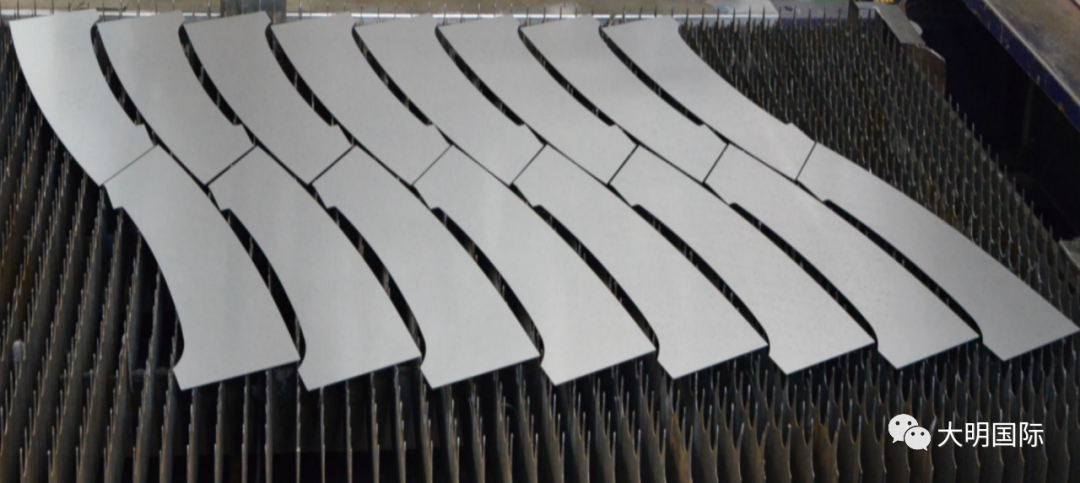

Κατά τη διάρκεια της παραγωγικής διαδικασίας, το τμήμα παραγωγής της Daiming Heavy Industry βασίζεται στην πλούσια εμπειρία της υποστήριξης πύργου πλυντηρίου, το τεχνικό τμήμα να κάνει καλή δουλειά στους κανονισμούς της διαδικασίας παραγωγής και την παραγωγή μαζί με τη δυσκολία του προϊόντος στο αρχικό στάδιο της παραγωγής ενός προς ένα αποσύνθεση. Όλα τα μέρη του έργου στο κέντρο επεξεργασίας Jiangsu Daming και Daming Jingjiang για την κοπή και την επεξεργασία, τη ροή υψηλής απόδοσης στην επόμενη συγκόλληση, το στρογγυλό κύκλο, την κάμψη και άλλες διαδικασίες, αντικατοπτρίζοντας πλήρως τα πλεονεκτήματα της ομαδικής συνεργασίας. Καθώς τα προϊόντα είναι όλα λεπτά πλάκα από ανοξείδωτο χάλυβα ειδικό υλικό, πρέπει να εξετάσουμε την πλάκα τοίχου και την πλάκα πυθμένα συγκόλλησης εύκολη παραμόρφωση και άλλους παράγοντες, η Daiming Heavy Industry χρησιμοποίησε αυτόματη συγκόλληση πλάσματος, συγκόλληση που διαμορφώνει όμορφη, γρήγορη ταχύτητα συγκόλλησης, υψηλή απόδοση.

Λόγω του αυστηρού χρονοδιαγράμματος του πλοίου του ιδιοκτήτη, αντιμετωπίζοντας τις υψηλές απαιτήσεις ποιότητας και παράδοσης, η ομάδα έργου έκανε λογική ανάπτυξη για όλη την πρόοδο και ξεπέρασε τις δυσκολίες στο πλαίσιο των κοινών προσπαθειών. Χρειάστηκαν μόνο 45 ημέρες από την είσοδο των υλικών έως την παράδοση του πρώτου προϊόντος, ολοκληρώνοντας μια σειρά διαδικασιών από την εκφόρτωση, τη συγκόλληση και τη συγκόλληση, την κάμψη, την περιτύλιξη, τη συναρμολόγηση, τη διάτρηση, το πάστωμα και την παθητικοποίηση. Η επιτυχής προώθηση αυτού του έργου αντιπροσωπεύει ένα άλμα στην ικανότητα υποστήριξης της παραγωγής της Daming Heavy Industry και θέτει ένα νέο σημείο αναφοράς.

Επιπλέον, η Daming ταίριαξε επίσης το εσωτερικό διάφραγμα του μεγαλύτερου σε χωρητικότητα χημικού δεξαμενόπλοιου 49.000 τόνων της Hudong-Zhonghua, το οποίο επεξεργάστηκε με ανοξείδωτο χάλυβα duplex. Στηριζόμενη στο περιφερειακό πλεονέκτημα της τοποθεσίας του έργου και στο ισχυρό πλεονέκτημα εκτεταμένης επεξεργασίας της Daming Heavy Industry, η Daming Heavy Industry παρείχε στους πελάτες τις ακόλουθες υπηρεσίες: "Αφαίρεση σχεδίων - αφαίρεση υλικού - λοξοτομή - συγκόλληση - κάμψη - διανομή". -Συγκόλληση - κάμψη - διανομή" η όλη διαδικασία των υποστηρικτικών υπηρεσιών βαθιάς επεξεργασίας "μπάτλερ", αλλά και η μεγαλύτερη στον κόσμο χωρητικότητα των βασικών συστατικών των χημικών δεξαμενόπλοιων από ανοξείδωτο χάλυβα του συνολικού εντοπισμού της κλασικής περίπτωσης.

Τέτοια επιτεύγματα υποστήριξης είναι η βήμα προς βήμα μαρτυρία της φήμης των υπηρεσιών της Daming στη ναυπηγική και υπεράκτια βιομηχανία, και είναι επίσης το αποτέλεσμα των προσπαθειών της Daming για βαθιά όργωμα της βιομηχανίας. Ποια είναι τα διαφοροποιημένα ανταγωνιστικά πλεονεκτήματα της Daming στην υποστήριξη του σχετικού με τη ναυπηγική βιομηχανία υπεράκτιου εξοπλισμού;