Περίπτωση υπηρεσίας:

Daming Hangzhou κέντρο επεξεργασίας από ανοξείδωτο χάλυβα υπηρεσία προϊόντων για κλωστοϋφαντουργικές επιχειρήσεις λαμβάνει υψηλούς επαίνους (2021)

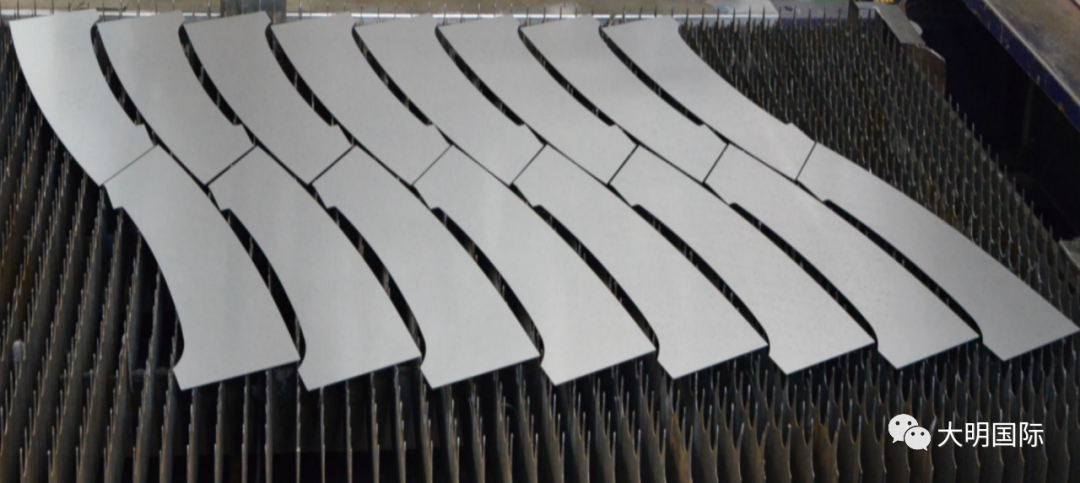

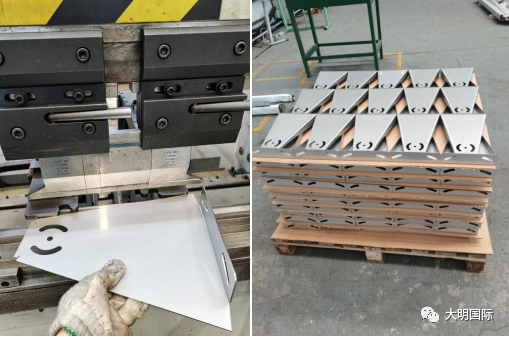

Η Hangzhou Daming έλαβε μια παρτίδα παραγγελιών από κλωστοϋφαντουργικές επιχειρήσεις. Η πλάκα παραγγελίας είναι από ανοξείδωτο χάλυβα πάχους 2mm 304, που περιλαμβάνει διαδικασία κοπής και κάμψης. Λόγω των υψηλών απαιτήσεων αυτής της παραγγελίας, το Κέντρο Επεξεργασίας της Hangzhou μειώνει αποτελεσματικά τα σφάλματα τοποθέτησης και διαστάσεων με κοπή μέσω οπτικών ινών με εξοπλισμό Thruflex για να διασφαλίσει την απαιτούμενη ακρίβεια κοπής του προϊόντος.

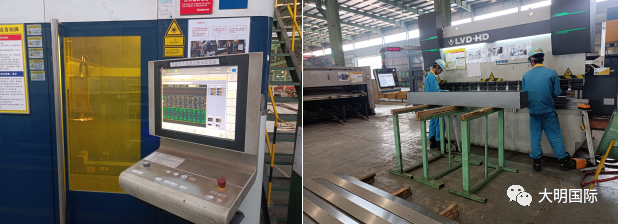

Επιπλέον, το μοτίβο κάμψης αυτής της παραγγελίας είναι ειδικό και περιέχει κάμψη με λοξές άκρες, η οποία απαιτεί μεγαλύτερη ακρίβεια διαστάσεων για την κάμψη. Σύμφωνα με τα ειδικά χαρακτηριστικά του γραφήματος, το τμήμα παραγωγής του κέντρου επεξεργασίας Hangzhou επέλεξε για την παραγωγή τη μηχανή κάμψης 100T που σφυρηλατήθηκε από την Huang forging. Η κίτρινη σφυρηλατημένη μηχανή κάμψης 100T έχει δύο ανεξάρτητα πίσω εμπόδια (backstop), σύμφωνα με τις ανάγκες της ατομικής κίνησης προς τα εμπρός και πίσω, αριστερά και δεξιά, μειώνοντας αποτελεσματικά το σφάλμα διαστάσεων της κάμψης της λοξής άκρης και τελικά ο πελάτης επαίνεσε ιδιαίτερα αυτή την παρτίδα των αγαθών που παραδόθηκαν.

Hangzhou Daming διαδικασία πολλαπλών καναλιών που υποστηρίζει μια γνωστή επιχείρηση κλωστικής μηχανής (2021)

Το Κέντρο Επεξεργασίας Daming Hangzhou ταίριαξε μια παρτίδα προϊόντων για μια διάσημη επιχείρηση κλωστηρίων στην επαρχία Zhejiang και ο υψηλός ποιοτικός έλεγχος και η αποτελεσματική παράδοση των προϊόντων άφησαν βαθιά εντύπωση στον πελάτη.

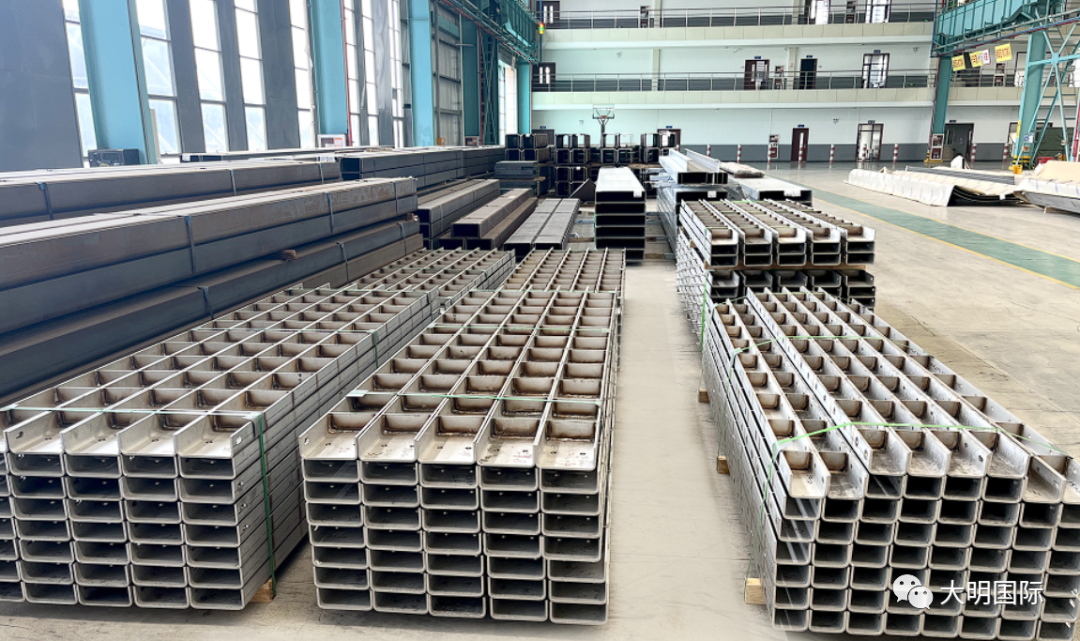

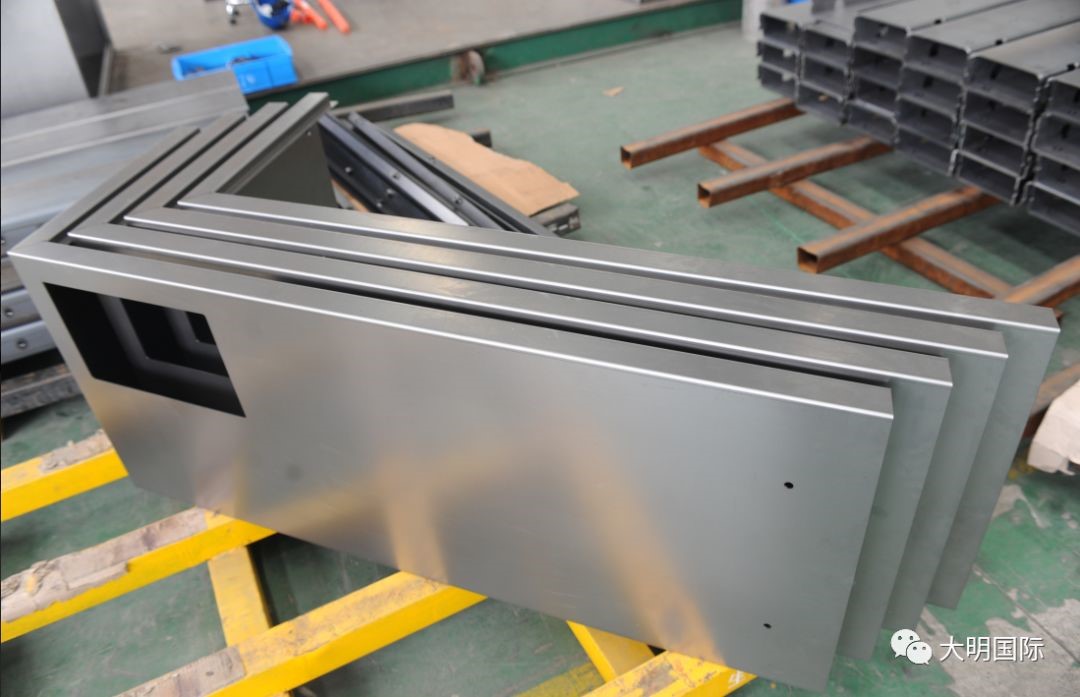

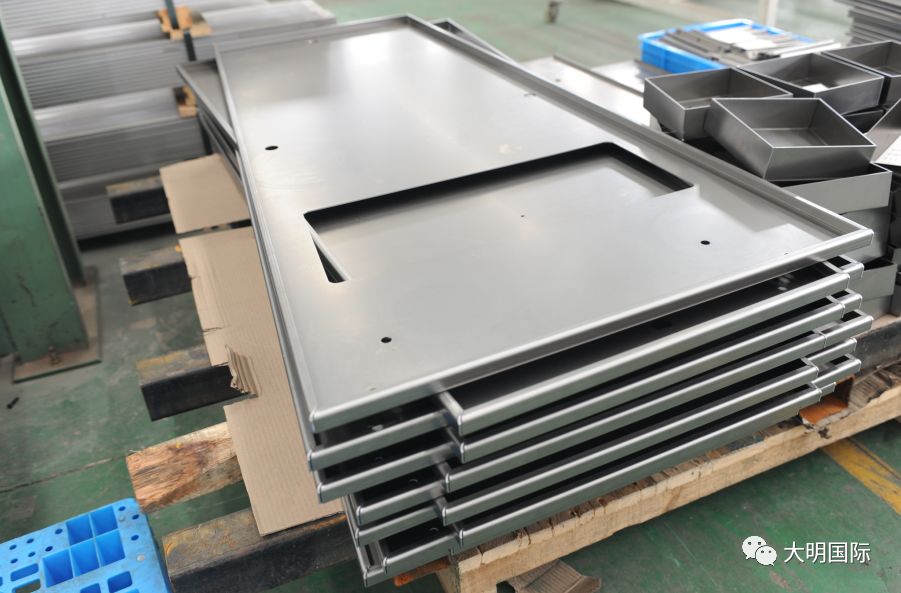

Αυτή η παρτίδα προϊόντων πρέπει να περάσει από πολλές διαδικασίες ισοπέδωσης, κοπής, κάμψης, τοποθέτησης και συγκόλλησης, το κέντρο επεξεργασίας Daming Hangzhou παρέχει υπηρεσίες μιας στάσης για τον πελάτη χάρη στην πλούσια εμπειρία επεξεργασίας και την τέλεια αλυσίδα παραγωγής και επεξεργασίας. Επί του παρόντος, η πρώτη παρτίδα των 57 συνόλων προϊόντων έχει ολοκληρωθεί με επιτυχία και έχει αποσταλεί στον πελάτη 2 ημέρες νωρίτερα, γεγονός που εξοικονομεί σε μεγάλο βαθμό τον επόμενο κύκλο επεξεργασίας του πελάτη και ο πελάτης είναι επίσης πολύ ικανοποιημένος με την ποιότητα επεξεργασίας των προϊόντων και δήλωσε ότι θα προσθέσει και πάλι περισσότερες από 100 σειρές παραγγελιών προϊόντων μηχανής κλώσης.

Το κέντρο επεξεργασίας Daming Hangzhou έχει αρκετή εμπειρία στη βαθιά επεξεργασία για τις επιχειρήσεις μηχανών κλώσης (2021)

Το Κέντρο Επεξεργασίας Daming Hangzhou ταίριαξε και πάλι με επιτυχία 99 σύνολα προϊόντων κλωστικής μηχανής για μια διάσημη εγχώρια επιχείρηση κλωστικής μηχανής, η οποία ενίσχυσε την προσκόλληση του πελάτη και κέρδισε τον έπαινο του πελάτη.

Αυτή η παρτίδα παραγγελιών πρέπει να περάσει από μια σειρά διαδικασιών, όπως ισοπέδωση, κοπή, κάμψη, ισοπέδωση, βρύση, συγκόλληση κ.λπ. Με την υπηρεσία "μιας στάσης", την πλούσια εμπειρία επεξεργασίας και την τέλεια ικανότητα επεξεργασίας εξοπλισμού, το Κέντρο Επεξεργασίας Daming Hangzhou βελτιώνει συνεχώς την αποτελεσματικότητα της επεξεργασίας, η οποία αναγνωρίζεται ιδιαίτερα από τον πελάτη και εμβαθύνει την εμπιστοσύνη του πελάτη στο Κέντρο Επεξεργασίας Daming Hangzhou.

Κοπή

Bengding

Συγκόλληση

Μεταφορά

Συμπληρωματικά προϊόντα

Ξεπερνώντας τα προβλήματα και βελτιώνοντας την αποδοτικότητα, το κέντρο επεξεργασίας Daming Hangzhou έχει φτάσει σε ρεκόρ στην υποστήριξη κλωστοϋφαντουργικών μηχανημάτων (2020)

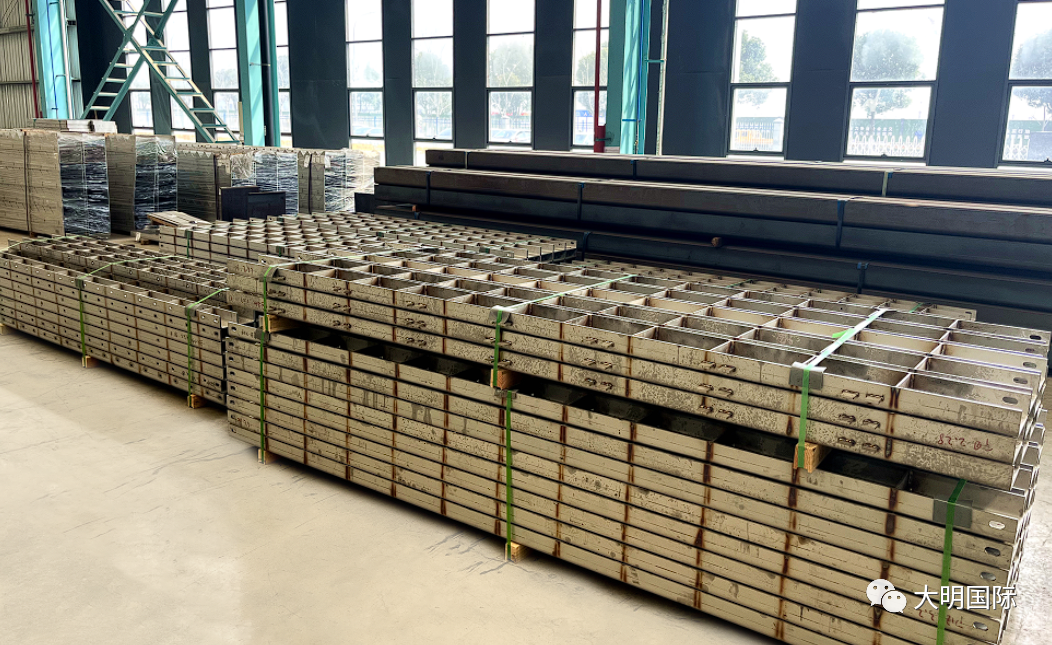

Στις αρχές Ιουλίου, το κέντρο επεξεργασίας Daming Hangzhou έλαβε μια πρόσθετη παραγγελία από έναν πελάτη κλωστοϋφαντουργικών μηχανημάτων, από την πρώτη παρτίδα των 40 σετ σε 136 σετ, και ο μηνιαίος όγκος εργασιών ήταν κοντά στο όριο της παραγωγικής ικανότητας του κέντρου επεξεργασίας (η θεωρητική παραγωγική ικανότητα ενός μήνα είναι περίπου 100 σετ). Daming Hangzhou κέντρο επεξεργασίας τελικά μέσα από τις προσπάθειες όλου του προσωπικού, η πραγματική ολοκλήρωση των παραγγελιών κλώση μηχανή τον Ιούλιο 117 σύνολα, περισσότερο από 84 σύνολα τον Απρίλιο, 33 σύνολα, την αποτελεσματικότητα της επεξεργασίας από 3 σύνολα την ημέρα σε 4 σύνολα την ημέρα επίπεδο, εγκαίρως για να ανταποκριθεί στις απαιτήσεις προθεσμία του πελάτη.

Οι πελάτες απαιτούν την προμήθεια ενός μηνός πρέπει να φτάσει σε περισσότερα από 100 σύνολα, το τμήμα παραγωγής είναι ανήσυχο για την επείγουσα ανάγκη των πελατών, το έργο παραγωγής για την κατανομή του εξευγενισμού, η πρώτη διαδικασία της κοπής του υλικού για να θέσει συγκεκριμένες απαιτήσεις, δύο βάρδιες των 12 ωρών βάρδιες για να ανοίξει την πλήρη δύναμη της εφαρμογής της κλιμακωτής γεύματα, δείπνο, το Σαββατοκύριακο βάρδια εφαρμογή του συστήματος διακεκομμένη εναλλαγή για να εξασφαλιστεί ότι ο εξοπλισμός είναι 24 ώρες χωρίς διακοπή, διαδικασία συγκόλλησης λόγω της έλλειψης ανθρώπινου δυναμικού, και εγκαίρως με τις αδελφές μονάδες Daming Λόγω της έλλειψης ανθρώπινου δυναμικού στη διαδικασία συγκόλλησης, η εταιρεία επικοινώνησε εγκαίρως με την αδελφή μονάδα Daming Processing Center για να λάβει την υποστήριξη του προσωπικού, πραγματοποιώντας τη "διαλειτουργικότητα του προσωπικού και της επιχειρηματικής σύνδεσης", η οποία αντικατοπτρίζει τον σημαντικό ρόλο του μηχανισμού σύνδεσης του ομίλου.

Η θερμοκρασία στο Hangzhou τον Ιούλιο είναι καυτή, η υψηλότερη θερμοκρασία έχει φτάσει τους 36 ℃, το προσωπικό κοπής υλικού που ιδρώνει για να σπεύσει τις παραγγελίες!

Διαδικασία χύτευσης με τη χρήση "μικρού, γρήγορου και ακριβούς" εξοπλισμού κάμψης για παραγγελίες βιασύνης.

Ο εξοπλισμός ψεκασμού της μηχανής κλώσης Daming υποστηρίζοντας τον εξοπλισμό ψεκασμού είναι ιδιαίτερα επαινετός (2019)

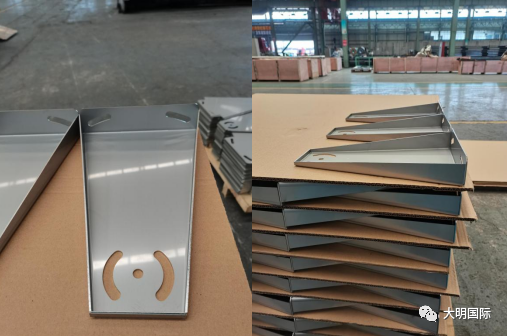

Πρόσφατα, οι δεξαμενές ψεκασμού που ανατέθηκαν από την Jiangsu Daming και επεξεργάστηκαν από την Daming Precision Industry έχουν αποσταλεί και έχουν αναγνωριστεί ιδιαίτερα από τους πελάτες.

Είναι κατανοητό ότι η επεξεργασία της δεξαμενής ψεκασμού υποστηρίζει τα κλωστοϋφαντουργικά μηχανήματα για την αντιμετώπιση των υπολειμμάτων του εξοπλισμού καθαρισμού της προηγούμενης διαδικασίας, συνολικά 4 σύνολα, η περίοδος παράδοσης μόνο μία εβδομάδα. Υιοθετώντας υλικό 316L με πάχος 2mm, η επεξεργασία περιλαμβάνει ισοπέδωση, κοπή με λέιζερ, κάμψη, κινηματογράφηση και άλλες διαδικασίες, καθώς η εκτεθειμένη επιφάνεια πρέπει να είναι ταινία μονής όψης. Αντιμετωπίζοντας την κατάσταση των υψηλών απαιτήσεων ποιότητας του προϊόντος και του στενού χρόνου, η παραγωγή, η τεχνολογία και οι πωλήσεις της Daming συντονίστηκαν μεταξύ τους και εκμεταλλεύτηκαν τον εισαγόμενο εξοπλισμό και την ώριμη εμπειρία επεξεργασίας και τελικά ικανοποίησαν ομαλά τις απαιτήσεις του πελάτη και έλαβαν καλά σχόλια.

Η ολοκληρωμένη υπηρεσία αντιστοίχισης της Daming για τη βιομηχανία μηχανών κλώσης εισέρχεται σε ένα νέο στάδιο (2019)

Πρόσφατα, η πρώτη παρτίδα παραγγελιών για μια κορυφαία επιχείρηση κλωστοϋφαντουργικών μηχανημάτων στην επαρχία Zhejiang, που αναπτύχθηκε από κοινού από το Τμήμα Ανάπτυξης Αγοράς και το Κέντρο Επεξεργασίας Hangzhou του Ομίλου Daming, παραδόθηκε με επιτυχία, γεγονός που σηματοδοτεί ότι η ολοκληρωμένη υπηρεσία διανομής του Ομίλου Daming στον κλάδο των κλωστοϋφαντουργικών μηχανημάτων έχει εισέλθει σε ένα ολοκαίνουργιο στάδιο.

Αυτή τη φορά, η Daming παρείχε στην επιχείρηση κλωστοϋφαντουργικών μηχανημάτων ένα πλήρες σετ εξαρτημάτων λαμαρίνας για τη μηχανή συστροφής. Καθώς το προϊόν περιλαμβάνει στη συνέχεια διαδικασίες επιφανειακής επίστρωσης και συνολικής συναρμολόγησης, η επιπεδότητα της επιφάνειας, η ακρίβεια της απόστασης των οπών και η ομαλότητα των άκρων σχετίζονται άμεσα με τον κύκλο παραγωγής και τη διάρκεια ζωής του τελικού προϊόντος, οπότε εκτός από τις αυστηρές απαιτήσεις για την ημερομηνία παράδοσης, το ποσοστό επιτυχίας όλων των δειγματοληψιών του προϊόντος πρέπει να φτάσει πάνω από 99%. Μετά από συνεχή έρευνα και αποσφαλμάτωση μεταξύ του τμήματος ανάπτυξης της αγοράς και των τμημάτων παραγωγής και των τεχνικών τμημάτων του κέντρου επεξεργασίας Hangzhou, βασιζόμενη στον προηγμένο εξοπλισμό επεξεργασίας και την πλούσια εμπειρία επεξεργασίας, η Daming παρέδωσε με επιτυχία την παραγγελία και όλα τα προϊόντα πέρασαν την επιθεώρηση ταυτόχρονα.

Τα τελευταία χρόνια, η κλωστοϋφαντουργία που αντιπροσωπεύεται από την τεχνολογία των χημικών ινών και των μη υφασμένων υλικών αναπτύσσεται καλά, γεγονός που οδηγεί στην ανάπτυξη της βιομηχανίας κλωστοϋφαντουργικών μηχανημάτων. Βασιζόμενος στα δικά του πλεονεκτήματα, ο όμιλος Daming παρέχει στους κατασκευαστές κλωστοϋφαντουργικών μηχανημάτων ένα πλήρες φάσμα ολοκληρωμένων υποστηρικτικών υπηρεσιών για εξοπλισμό βαφής και φινιρίσματος, εξοπλισμό πλύσης και σύστημα συστροφής. Με εννέα πλατφόρμες συνεχούς επεξεργασίας και τις δικές της υπηρεσίες logistics, μπορεί να μειώσει αποτελεσματικά το κόστος παραγωγής των πελατών, να συμπιέσει τον κύκλο παραγωγής και να βοηθήσει τους πελάτες να ενισχύσουν την ανταγωνιστικότητα των προϊόντων.

Η συνεχής επέκταση των δραστηριοτήτων στον κλάδο των κλωστοϋφαντουργικών μηχανημάτων επωφελείται επίσης από τη συνεργατική και εστιασμένη ανάπτυξη του Τμήματος Ανάπτυξης της Αγοράς και του Τμήματος Δημοσιότητας και Σχεδιασμού του Ομίλου. Από την κατάρτιση σε συνέδρια του κλάδου έως την επιτόπια τεχνική υποστήριξη των επιχειρήσεων, και από την προτίμηση υλικών έως τη βελτιστοποίηση της επεξεργασίας και της παραγωγής, τα πλεονεκτήματα της Daming και τα πλεονεκτήματα των υπηρεσιών της έχουν αναγνωριστεί από περισσότερες επιχειρήσεις, και επί του παρόντος, η Daming παρέχει υπηρεσίες υποστήριξης σε γνωστές επιχειρήσεις του κλάδου.

Υλικά υψηλής ποιότητας, επεξεργασία υψηλής ποιότητας, συνεργατική ανάπτυξη, συμβουλευτικές υπηρεσίες, η Daming ενώνει τα χέρια με την κλωστοϋφαντουργία και τη μεταποιητική βιομηχανία της Κίνας για να αναπτυχθούν μαζί.