Jingjiang Daming has completed the delivery of a 1,800-ton steel plate order for a major construction machinery manufacturer. The shipment was the company’s largest individual order fulfilled in September and marks a significant achievement in terms of scale, complexity, and execution.

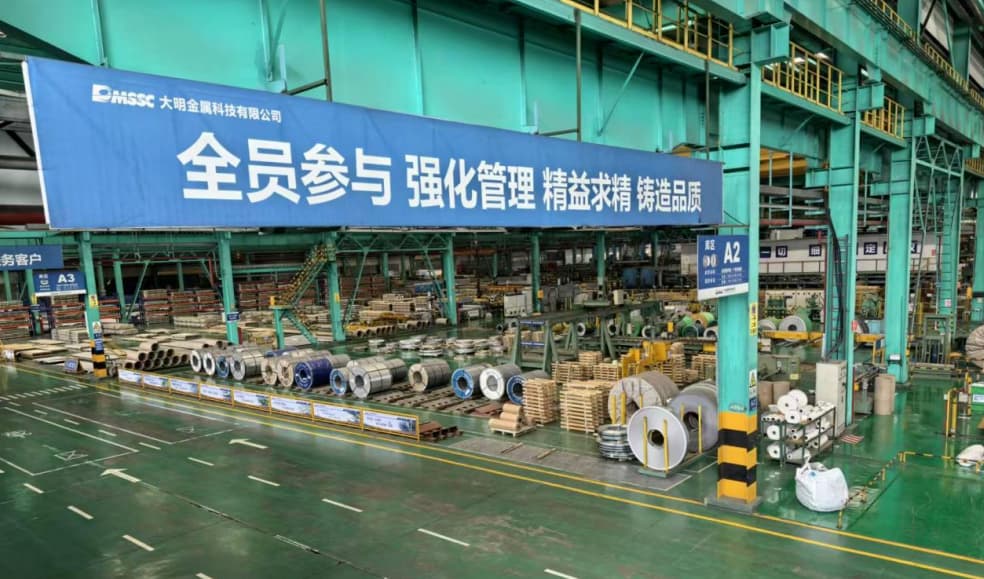

As one’s Daming’s eleven processing centers, Jiangjiang Daming focuses on carbon steel processing, supporting various industries including mining, construction machinery, energy, shipbuilding, etc.

Seamless Execution for a Time-Critical Project

The order, received in late September, involved stringent delivery deadlines and demanding technical specifications. Jingjiang Daming’s departments — from procurement and production to quality control and logistics — mobilized rapidly to meet the customer’s needs. The project was completed ahead of China’s National Day holiday, a period that typically brings production constraints due to rising order volumes. The success further reinforces Daming’s operational reliability and responsiveness under pressure.

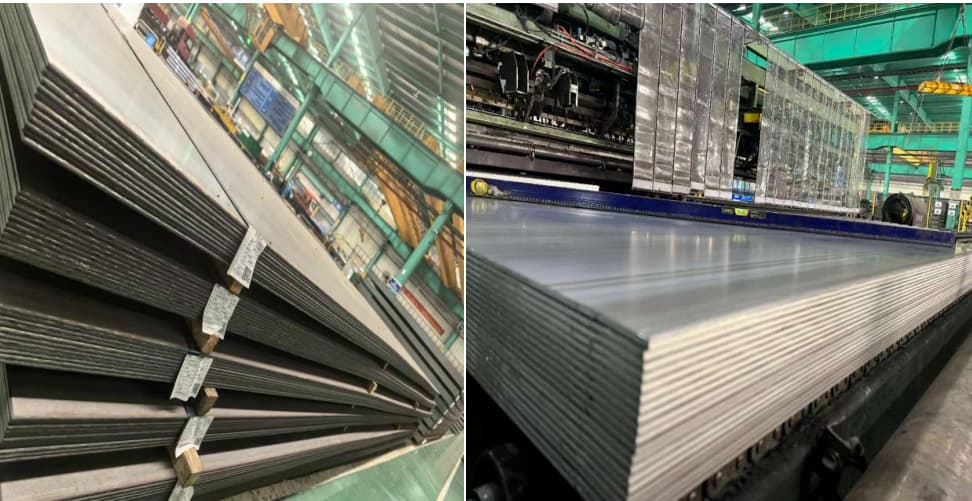

Strong Inventory Backbone Supports Fast Turnaround

One of the key enablers of this timely delivery was Jingjiang Daming’s strategic inventory management, particularly its robust stock of carbon steel plates. As one of the company’s core strengths, maintaining a large inventory — especially of medium-thickness (around 20mm) carbon steel plates — allows Daming to respond quickly to urgent or large-scale customer requirements without being delayed by upstream supply constraints.

This deep stockholding strategy not only shortens lead times but also gives customers greater flexibility in adjusting order volumes and specifications. For this project, Daming’s pre-stocked 20mm plates played a pivotal role in meeting tight production schedules and material availability, providing a critical edge over competitors who rely solely on just-in-time sourcing.

Advanced Steel Plate Processing Ensures Quality and Performance

The steel plates supplied were required to meet strict criteria for flatness, tensile strength, and mechanical consistency, as they were intended for use in high-precision downstream processes such as laser cutting, CNC bending, and robotic welding. These processes are essential in the fabrication of key construction machinery components — including frames, chassis elements, booms, and load-bearing arms — where dimensional accuracy and structural integrity are paramount.

To meet these quality demands, Jingjiang Daming utilized its VIGANO 20 cut-to-length machine, an advanced piece of European equipment specifically designed to reduce internal stress and enhance the flatness of thick steel plates. This investment in state-of-the-art processing equipment ensured compliance with technical standards and helped reduce the customer’s own processing time and costs.

Steel Plates in Construction Machinery: Critical Role and Requirements

Steel plates, especially medium and heavy carbon steel types, are foundational to the construction machinery industry. These materials must withstand extreme mechanical loads, dynamic vibrations, and abrasive environments, often over prolonged usage periods. Components fabricated from these plates are used in excavators, bulldozers, cranes, and other heavy equipment, where strength, weldability, and fatigue resistance are non-negotiable.

The construction machinery industry is asking for steel that has very specific measurements, consistent performance, and good surface quality to keep things running smoothly in automated manufacturing settings. Daming’s ability to supply pre-processed, precision-flat, high-quality steel plates makes it a preferred partner for leading OEMs in this space.

Cross-Functional Collaboration Drives Results

The successful delivery of this major order was the result of tight-knit coordination between the sales, production, and logistics teams. The sales department maintained ongoing dialogue with the customer to track changing specifications and timelines, while production operated at full capacity with strict quality control oversight. Logistics teams efficiently managed warehousing and transportation to ensure on-time delivery without compromising material condition.

The client praised Jingjiang Daming not only for the high quality of the steel products but also for the company’s ability to offer flexible, fast, and cost-effective service throughout the project lifecycle.

Long-Term Commitment to Industrial Partnerships

Looking ahead, Jingjiang Daming will continue to invest in supply chain resilience, processing innovation, and digital transformation to support the evolving needs of its customers in the construction machinery, shipbuilding, energy, and infrastructure sectors. By leveraging its strengths in inventory management, precision processing, and customer service, the company aims to provide even greater value and foster long-term partnerships with clients in high-performance industries.

“Maintaining a strong inventory base is not just a logistics strategy — it’s a commitment to being ready when our customers need us the most,” said a sales manager. “In today’s fast-paced industrial landscape, responsiveness is just as important as quality, and we strive to deliver both.”